Method for detecting equipment failure

A detection method and technology for equipment failure, applied in the direction of comprehensive factory control, instrumentation, sustainable manufacturing/processing, etc., can solve problems such as reducing equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (Embodiment 1) Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail

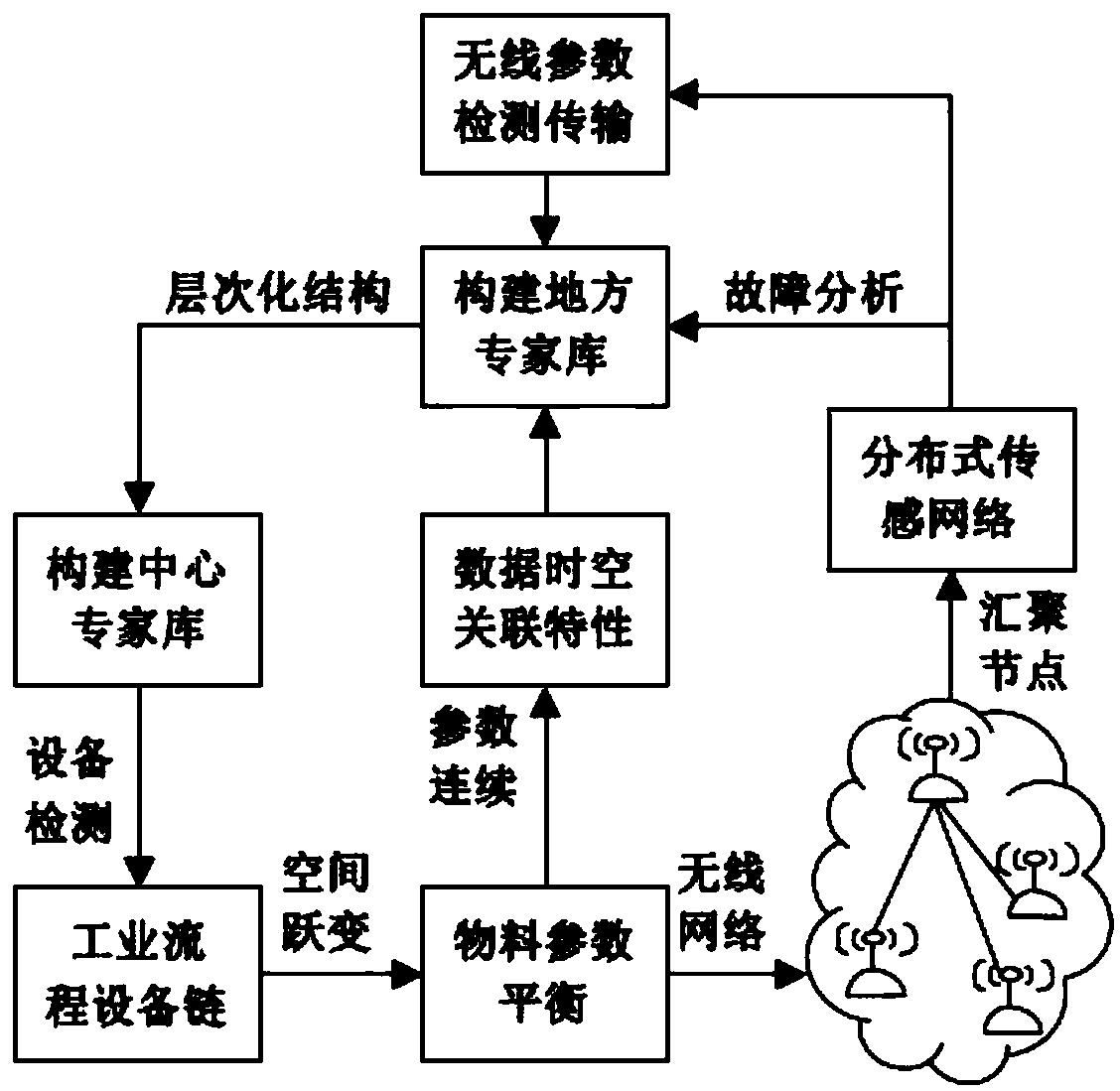

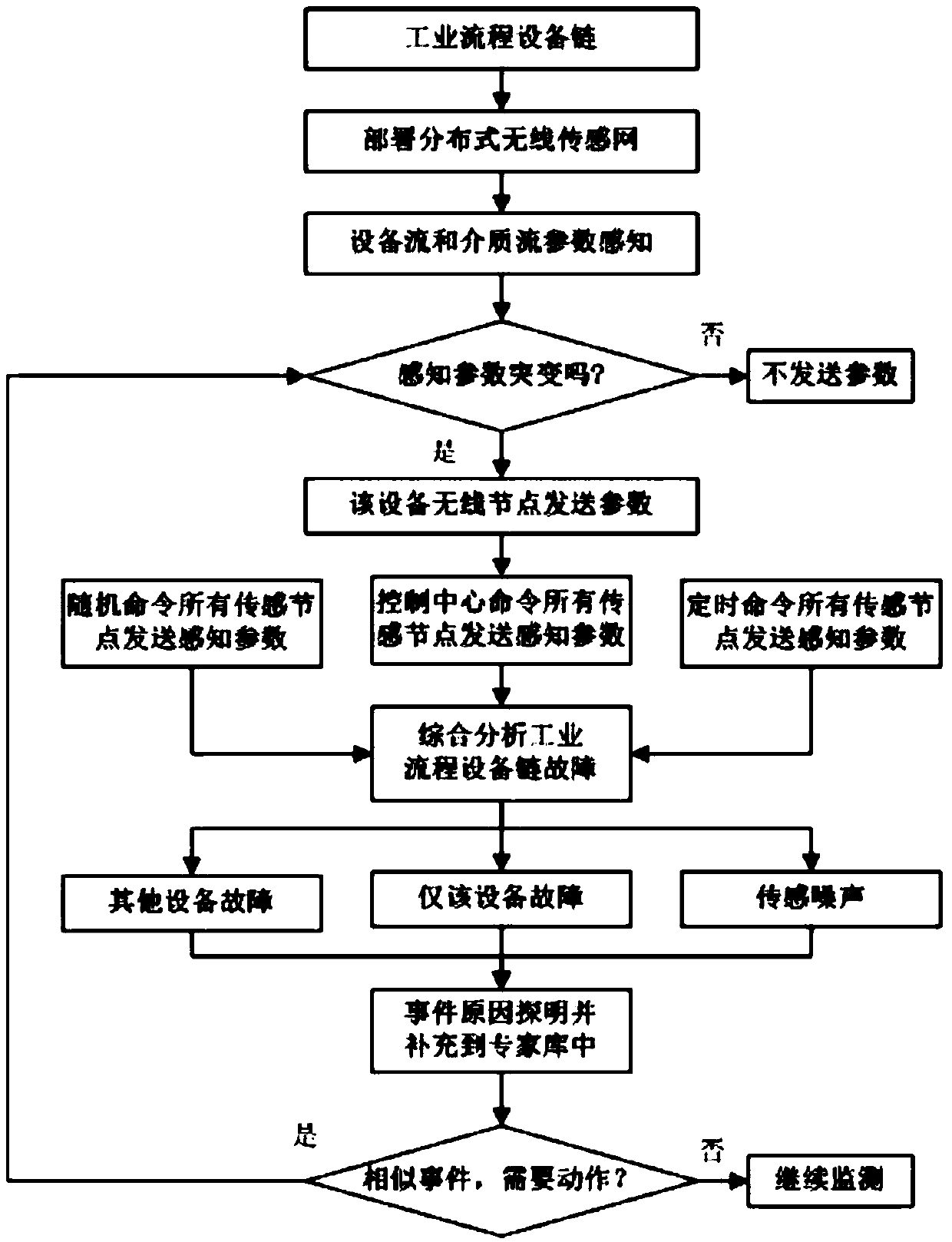

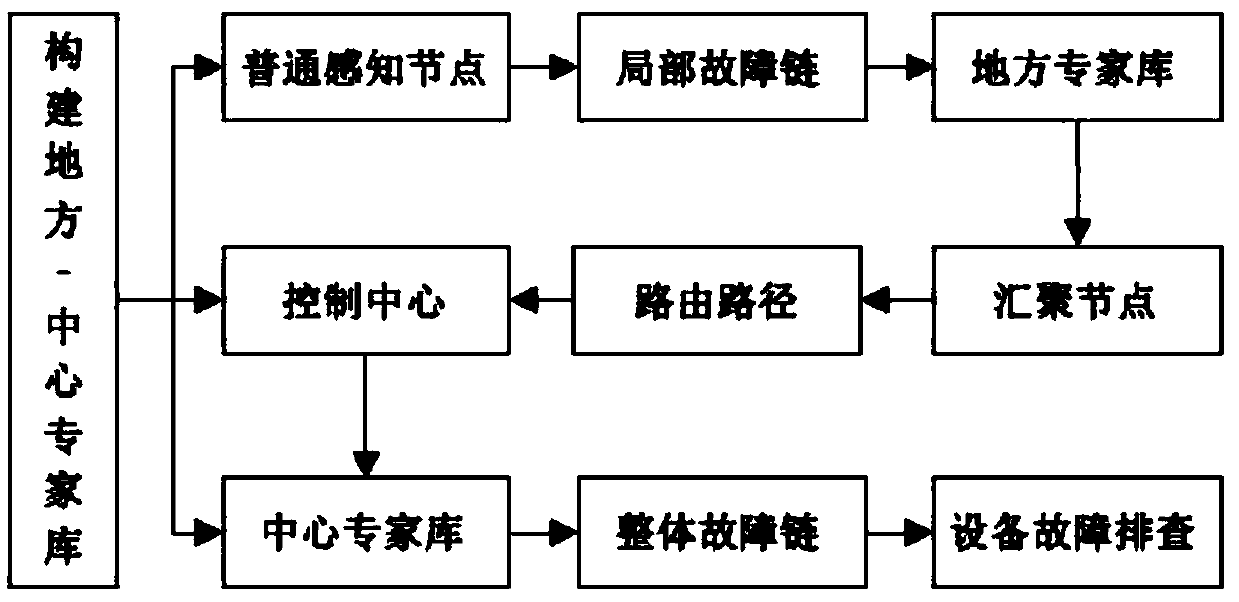

[0022] See Figure 1 to Figure 3 , according to the scattered distribution of each equipment in the industrial process equipment chain due to the process itself or the spatial layout requirements and the continuous characteristics of raw materials and medium flow, establish a parameter sensing and communication function (data transmission) including wireless sensing nodes and convergence nodes The wireless nodes self-organize to build a distributed wireless sensor network in the factory. Based on the distributed wireless sensor network, the detection method for the equipment failure in the industrial process equipment chain includes the following steps:

[0023] Step 1: Use the distributed wireless sensor network to perceive the industrial equipment operation and material parameters with frequency difference and time-space correlation, and buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com