A kind of manufacturing process of face paper in insulating steel paper

A production process and technology of facial paper, applied in papermaking, paper, papermaking and other directions, can solve problems such as poor evenness, and achieve the effects of improving evenness, increasing specific surface area, and preventing foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

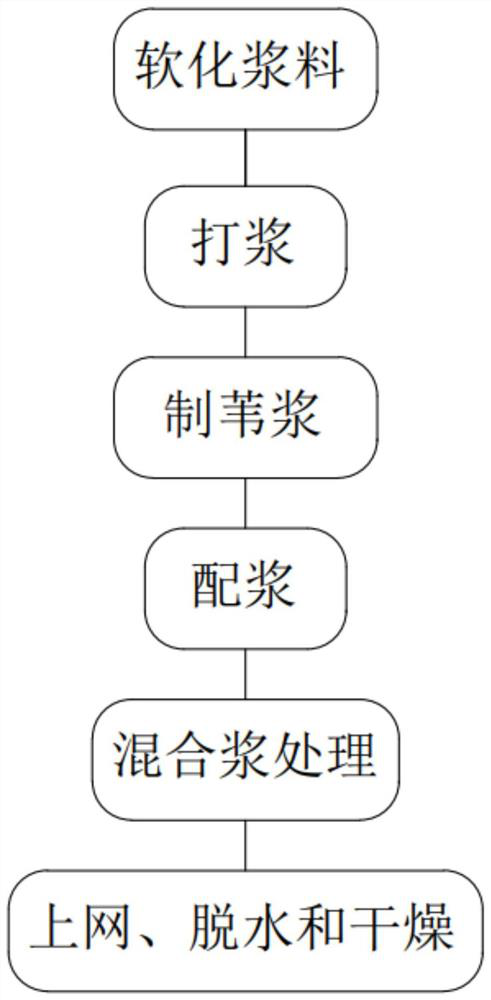

[0037] Embodiment one is basically as attached figure 1 Shown:

[0038] Step 1, soften the slurry: get the unbeaten wood fiber with a degree of polymerization of 1200n-1500n, send the wood fiber into the unbeaten pond, add a softener (quaternary ammonium salt type) that accounts for 0.33% of the total wood fiber in the unbeaten pond Softener), stirring evenly, after stirring for 25 minutes, the untapped wood pulp with a mass concentration of 3.5-4.0% and a wet weight of 17g was prepared.

[0039]Step 2, beating: send the unbeaten wood pulp through step 1 into a disc refiner for beating until the beaten wood pulp with a beating degree of 24-27°SR and a wet weight of 5-8g is obtained; wherein the disc refiner The number is at least two, all disc refiners are connected in series, the first disc refiner that does not enter the wood pulp adopts a cut-off type disc refiner (that is, the disc refiner uses a cut-off type disc refiner), and the rest of the disc refiners The disc refi...

Embodiment 2

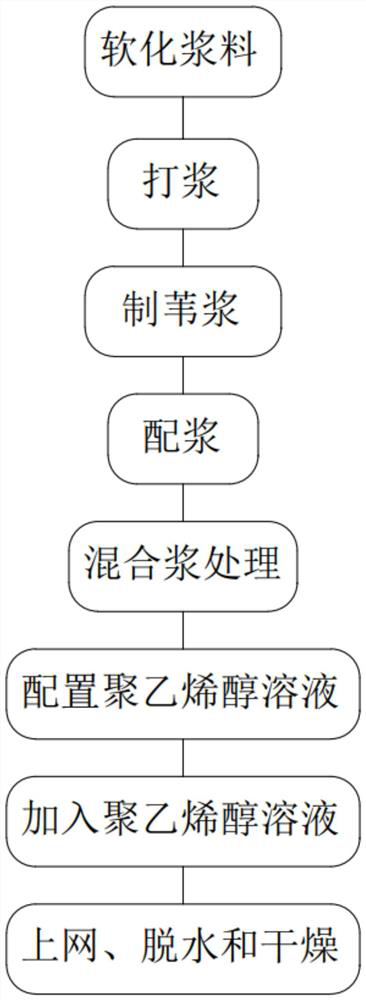

[0045] Embodiment two is basically as attached figure 2 As shown, the difference between embodiment two and embodiment one is that embodiment two has also carried out the following improvements:

[0046] There are also step A and step B between step five and step six of embodiment one, specifically as follows:

[0047] Step A, configure polyvinyl alcohol solution: take polyvinyl alcohol with a melting temperature of 100°C, the content of polyvinyl alcohol accounts for 0.9% of the total wood fiber content, dissolve polyvinyl alcohol in water at 100°C, and obtain a mass concentration of 1%. polyvinyl alcohol solution;

[0048] Step B, add polyvinyl alcohol solution: add the polyvinyl alcohol solution that has completed step A to the mixed slurry that has completed step 5; specifically, send the mixed slurry that has completed step 5 into the conical high-level tank, and when the mixed slurry enters In the case of a conical high-level tank, use a metering pump to add the polyv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com