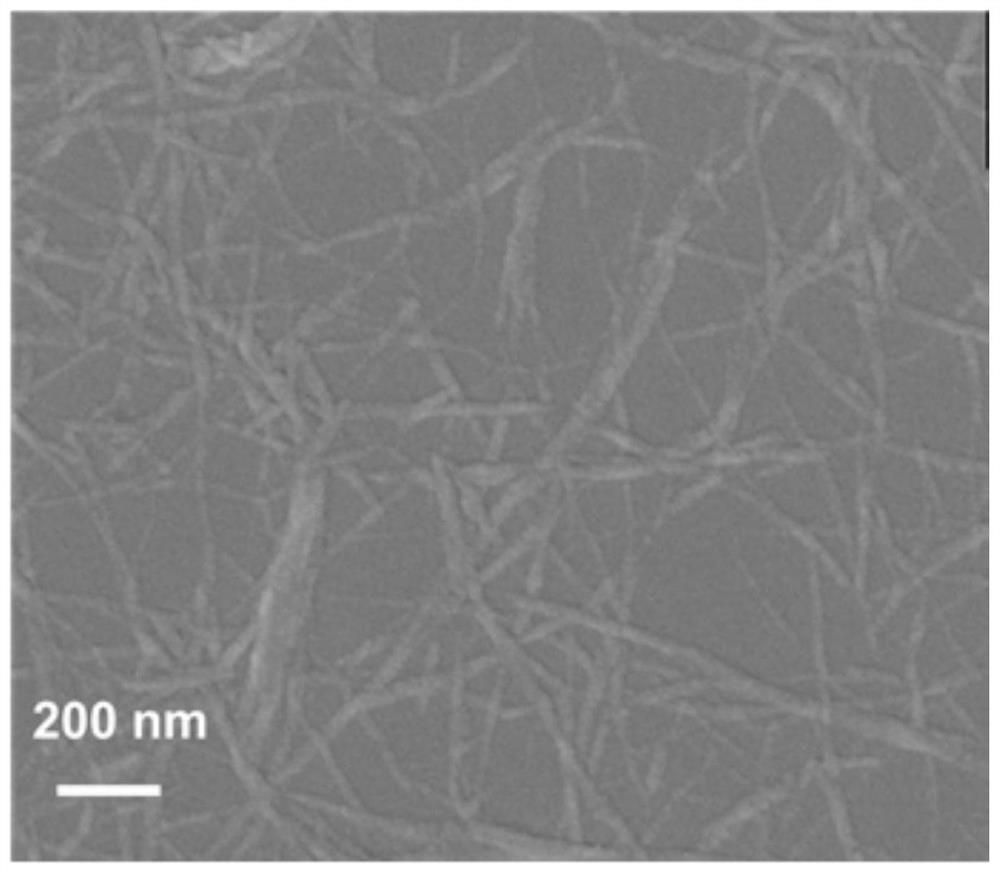

Plant-based cellulose nanofibril as well as preparation method and application thereof

A nanofibril and cellulose technology, which is applied in the post-processing of cellulose pulp, fiber raw material processing, pulp beating method, etc., can solve the problems of staying in the laboratory research stage, less large-scale production, and large energy consumption. The effect of promoting dissociation and miniaturization, promoting fibrillation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing plant-based cellulose nanofibrils of the present embodiment, the specific preparation steps are as follows:

[0039] (1) Ball milling treatment: the bleaching chemical thermomechanical slurry is configured into a mixed solution with a concentration of 1.0% (w / w), and 160 g of the mixed slurry quality is poured into a 500 mL ball milling tank, and a large ball (diameter: 10 mm ) and small balls (diameter: 6mm), wherein the mass ratio of large balls to small balls is 3:2. And control the mass ratio of mixing balls and slurry dry to 30:1. During the ball milling process, the rotating speed of the ball mill was set to 400rpm. In order to avoid overheating of the slurry, the ball milling was set for 5 minutes, and the suspension was 5 minutes as a cycle. The ball milling time was 0.5h to obtain the ball milled slurry.

[0040] (2) High-speed shearing treatment: the slurry after the ball milling treatment obtained in step (1) is configured into a suspe...

Embodiment 2

[0044] A method for preparing plant-based cellulose nanofibrils of the present embodiment, the specific preparation steps are as follows:

[0045] (1) Ball milling treatment: the bleaching chemical thermomechanical slurry is configured into a mixed solution with a concentration of 1.5% (w / w), and 180 g of the mixed slurry quality is poured into a 500 mL ball milling tank, and a large ball (diameter: 10 mm ) and small balls (diameter: 6mm), wherein the mass ratio of large balls to small balls is 4:2. And control the mass ratio of mixing balls and slurry dry to 35:1. During the ball milling process, the rotating speed of the ball mill was set to 400rpm. In order to avoid overheating of the slurry, the ball milling was set for 7 minutes, and a cycle of 7 minutes was suspended. The ball milling time was 1 hour to obtain the ball milled slurry.

[0046] (2) High-speed shearing treatment: the slurry after the ball milling treatment obtained in step (1) is configured into a suspensi...

Embodiment 3

[0050] A method for preparing plant-based cellulose nanofibrils of the present embodiment, the specific preparation steps are as follows:

[0051] (1) Ball milling treatment: the bleaching chemical thermomechanical slurry is configured into a mixed solution with a concentration of 2.0% (w / w), and 200 g of the mixed slurry quality is poured into a 500 mL ball milling tank, and a large ball (diameter: 10 mm ) and small balls (diameter: 6mm), wherein the mass ratio of large balls to small balls is 5:2. And control the mass ratio of mixing balls and slurry dry to 35:1. During the ball milling process, the rotating speed of the ball mill was set at 500rpm. In order to avoid overheating of the slurry, the ball milling was set for 8 minutes, and a cycle of pausing for 8 minutes was used. The ball milling time was 1.5 hours to obtain the ball milled slurry.

[0052] (2) High-speed shearing treatment: the slurry after the ball milling treatment obtained in step (1) is configured into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com