Application of bacillus DL-1 whole cell in catalytic resolution of styralyl acetate

A technology of styroyl acetate and Bacillus, applied in bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of expensive reagents, high cost, large pollution, etc., and achieve high application value and high substrate resistance. The effects of receptivity and optical selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the identification of bacillus strain

[0024] The strain Bacillus sp.DL-1 after screening and purification was identified by its conserved 16S rRNA sequence. 16S rRNA universal primers 27F: 5'-AGAGTTTATCCTGGCTCAG-3'; and 1492R: 5'-GGTTACCTTGTTACGACTT-3' were used for PCR amplification using the Bacillus DL-1 bacterial liquid as a DNA template. Set up the reaction system shown in Table 1:

[0025] Table 1 PCR reaction system

[0026]

[0027] PCR amplification conditions: pre-denaturation at 94°C for 10 min, followed by denaturation at 94°C for 30 s, annealing at 56°C for 30 s, extension at 72°C for 2 min and 30 s, and 30 cycles; finally, extension at 72°C for 10 min, and cooling to 18°C. The amplified products were detected by 1% agarose gel electrophoresis, and then sent to Meiji Biotechnology Co., Ltd. for bidirectional sequencing. After splicing the 16S rRNA sequence of the strain (its nucleotide sequence is shown in SEQ ID NO.1), the strain was ...

Embodiment 2

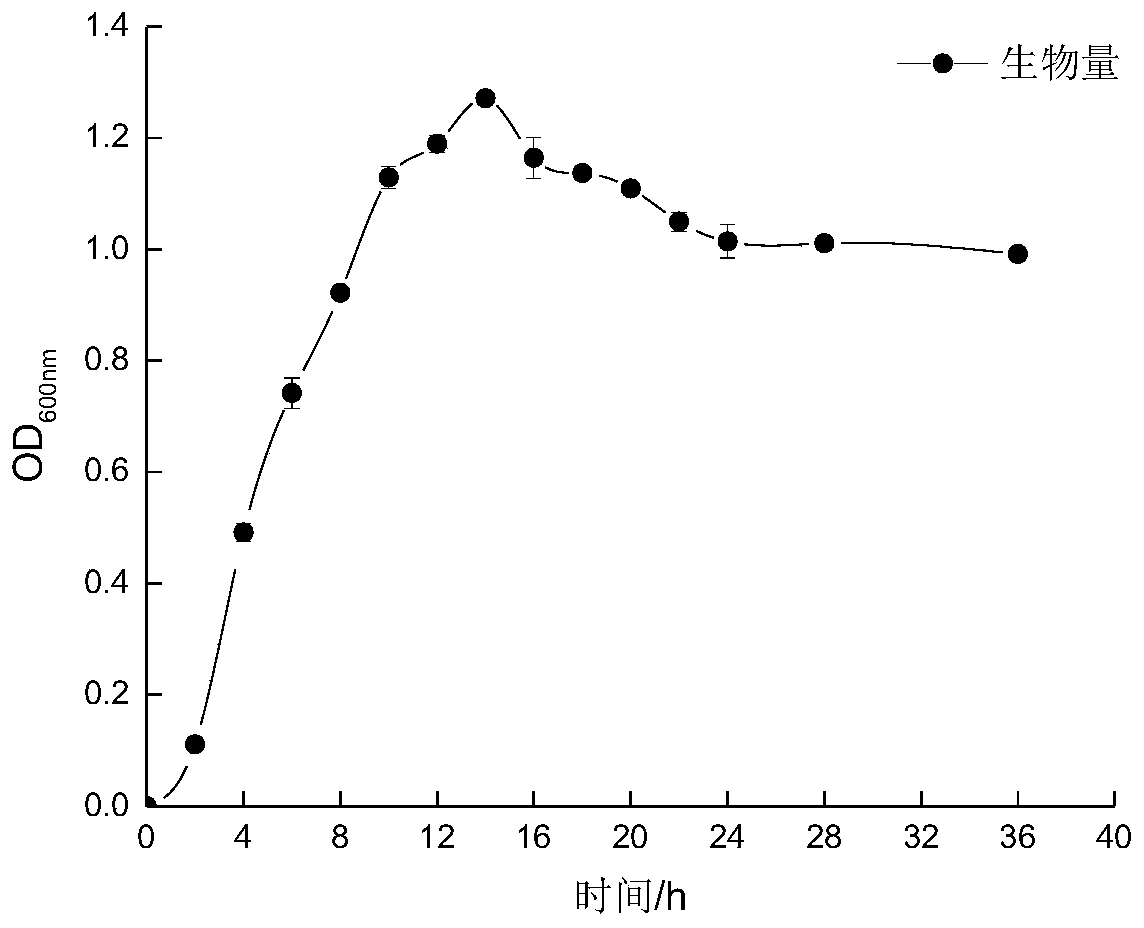

[0028] Example 2: Growth curve of Bacillus sp.DL-1

[0029] Streak the preserved Bacillus sp.DL-1 onto LB solid medium (1% tryptone, 0.5% yeast powder, 1% NaCl, 1.5% agar powder, solvent is water; above all are mass fractions), Cultivate at 37°C for 16 hours, then pick a single colony and inoculate it into 100 mL of LB liquid medium (1% tryptone, 0.5% yeast powder, 1% NaCl, the solvent is water; the above are all mass fractions), 200r / min, 37 Cultivate at ℃ for 12 hours to obtain seed solution, inoculate in LB liquid medium according to the inoculation amount of 1% v / v and cultivate at 200r / min, cultivate at 37℃, measure its biomass OD-600nm every 2h, the results are as follows figure 1 shown.

Embodiment 3

[0030] Example 3: Preparation of whole cells of Bacillus sp.DL-1

[0031] The seed solution of Bacillus sp.DL-1 was inoculated in skimmed milk powder liquid culture medium according to the inoculation amount of 1% v / v (dissolving 10 g high-protein skimmed high-calcium milk powder (purchased from Inner Mongolia Yili Industrial Group Co., Ltd.) in 1 L of water , sterilized at 115°C for 30min, and cooled to obtain) for fermentation culture, 200r / min, 37°C for 24h (the medium became clear), to obtain the fermentation liquid, centrifuged to remove the supernatant, and the cell pellet was sterilized with pH=7.2 Tris / HCl buffer was washed three times, and the cell pellet was collected by centrifugation to obtain whole cells of Bacillus sp.DL-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com