Treatment system for slaughter house wastewater

A wastewater treatment system and technology for slaughterhouses, applied in animal processing wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve problems such as ineffective wastewater treatment, and achieve enhanced wastewater treatment efficiency and scope of application The effect of widening and reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

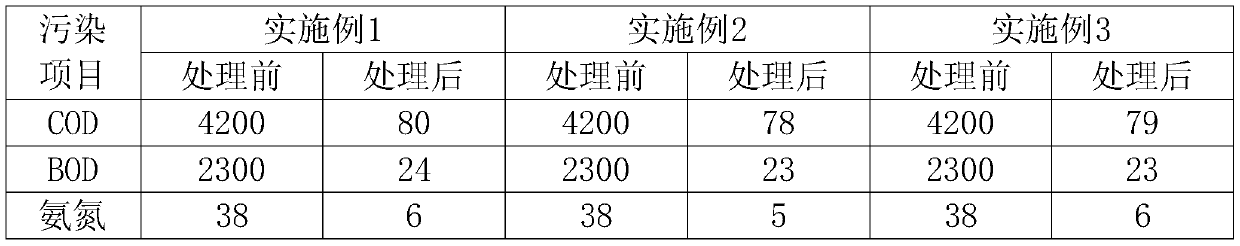

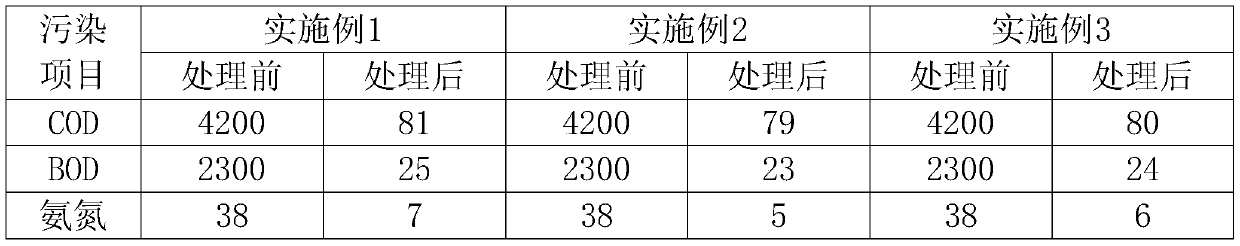

Embodiment 1

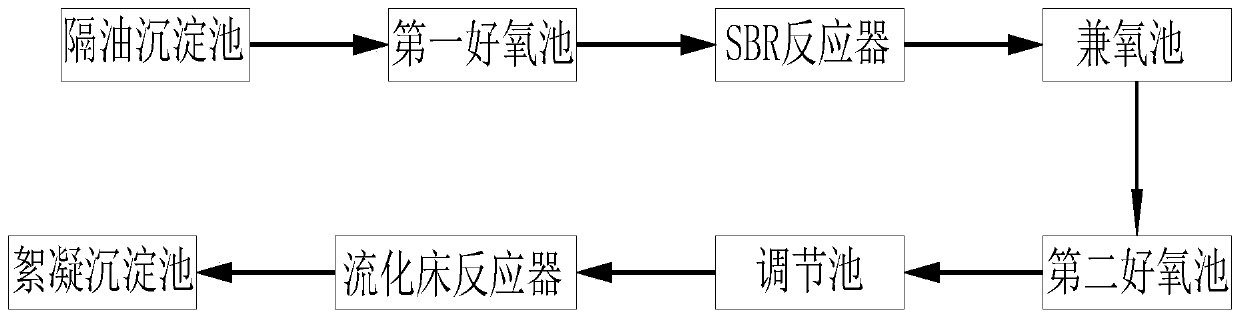

[0026] A slaughterhouse wastewater treatment system, comprising an oil separation sedimentation tank, a first aerobic tank, an SBR reactor, a facultative oxygen tank, a second aerobic tank, a regulating tank, a fluidized bed reactor, and a flocculation sedimentation tank connected in sequence, There are two mutually symmetrical sludge discharge pipes on the lower side of the oil separation sedimentation tank, which are connected to the sludge pool below the sludge discharge pipes, and a middle grid is installed at the outlet of the fluidized bed reactor. Coarse grids are installed at the outlet of the flocculation sedimentation tank, and screens are connected to both the middle grid and the coarse grid. The distance between the bars of the coarse grid is 50mm, and the distance between the bars of the medium grid is 30mm. The SBR reactor contains activated sludge, and a mixture of sawdust, diatom mud and peat soil is added to the activated sludge for domestication treatment, an...

Embodiment 2

[0032] A slaughterhouse wastewater treatment system, comprising an oil separation sedimentation tank, a first aerobic tank, an SBR reactor, a facultative oxygen tank, a second aerobic tank, a regulating tank, a fluidized bed reactor, and a flocculation sedimentation tank connected in sequence, There are two mutually symmetrical sludge discharge pipes on the lower side of the oil separation sedimentation tank, which are connected to the sludge pool below the sludge discharge pipes, and a middle grid is installed at the outlet of the fluidized bed reactor. Coarse grids are installed at the outlet of the flocculation sedimentation tank, and screens are connected to both the middle grid and the coarse grid. The distance between the bars of the coarse grid is 55 mm, and the distance between the bars of the medium grid is 35 mm. The SBR reactor contains activated sludge, and a mixture of sawdust, diatom mud and peat soil is added to the activated sludge for domestication treatment, ...

Embodiment 3

[0038]A slaughterhouse wastewater treatment system, comprising an oil separation sedimentation tank, a first aerobic tank, an SBR reactor, a facultative oxygen tank, a second aerobic tank, a regulating tank, a fluidized bed reactor, and a flocculation sedimentation tank connected in sequence, There are two mutually symmetrical sludge discharge pipes on the lower side of the oil separation sedimentation tank, which are connected to the sludge pool below the sludge discharge pipes, and a middle grid is installed at the outlet of the fluidized bed reactor. Coarse grids are installed at the outlet of the flocculation sedimentation tank, and screens are connected to both the middle grid and the coarse grid. The grid spacing of the coarse grid is 60mm, and the grid spacing of the medium grid is 40mm. The SBR reactor contains activated sludge, and a mixture of sawdust, diatom mud and peat soil is added to the activated sludge for domestication treatment, and the mass ratio of these t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com