Melt spinning component device capable of improving quality of super fine-denier filament

A technology of ultra-fine denier and spinning components, which is applied in the direction of spinneret assembly, filament forming treatment, textile and papermaking, etc., and can solve the problem of non-uniform fineness of finished filament tow, decrease of tow strength, and inconsistent melt quality and other problems, to achieve uniform quality, reduce broken ends, and avoid viscosity differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

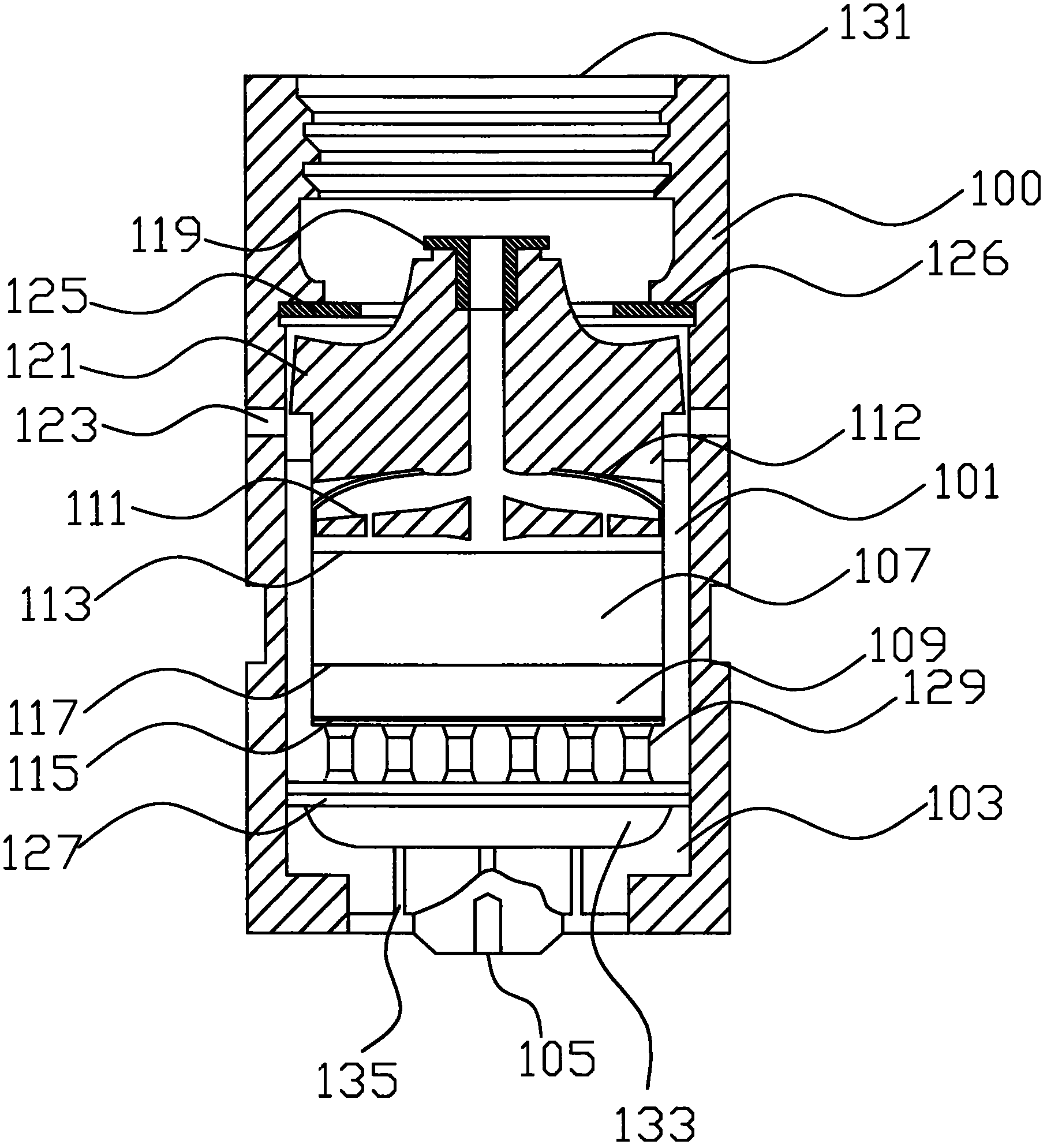

[0022] The structure and working process of the present invention will be further described with respect to an embodiment of the present invention with reference to the accompanying drawings.

[0023] Such as figure 1 As shown, a kind of melt-spinning assembly device capable of improving the quality of ultra-fine denier silk of the present invention comprises:

[0024] A component housing 100, the top of the component housing 100 is designed as an internal thread female screw 131, which is connected with the external thread male screw of the melt pipe of the spinning beam. A distribution cup mechanism 101 is provided in the middle of the assembly housing 100 , and a spinneret 103 and a tightening slot 105 are provided at the bottom of the assembly housing 100 .

[0025] It is worth mentioning that the two symmetrical tightening slots 105 are provided on the outside of the bottom of the component housing 100 , so that the operator can tighten the component by hand.

[0026] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com