Recovery process of dilute sulfuric acid in industrial wastewater

A technology for industrial wastewater and dilute sulfuric acid, applied in sulfur trioxide/sulfuric acid, sulfur compounds, inorganic chemistry, etc., can solve the problems of insufficient recycling and reuse of by-products, the precipitation rate of dilute sulfuric acid needs to be improved, and the equipment is corrosive. , to achieve the effect of difficult equipment, high safety and avoiding side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

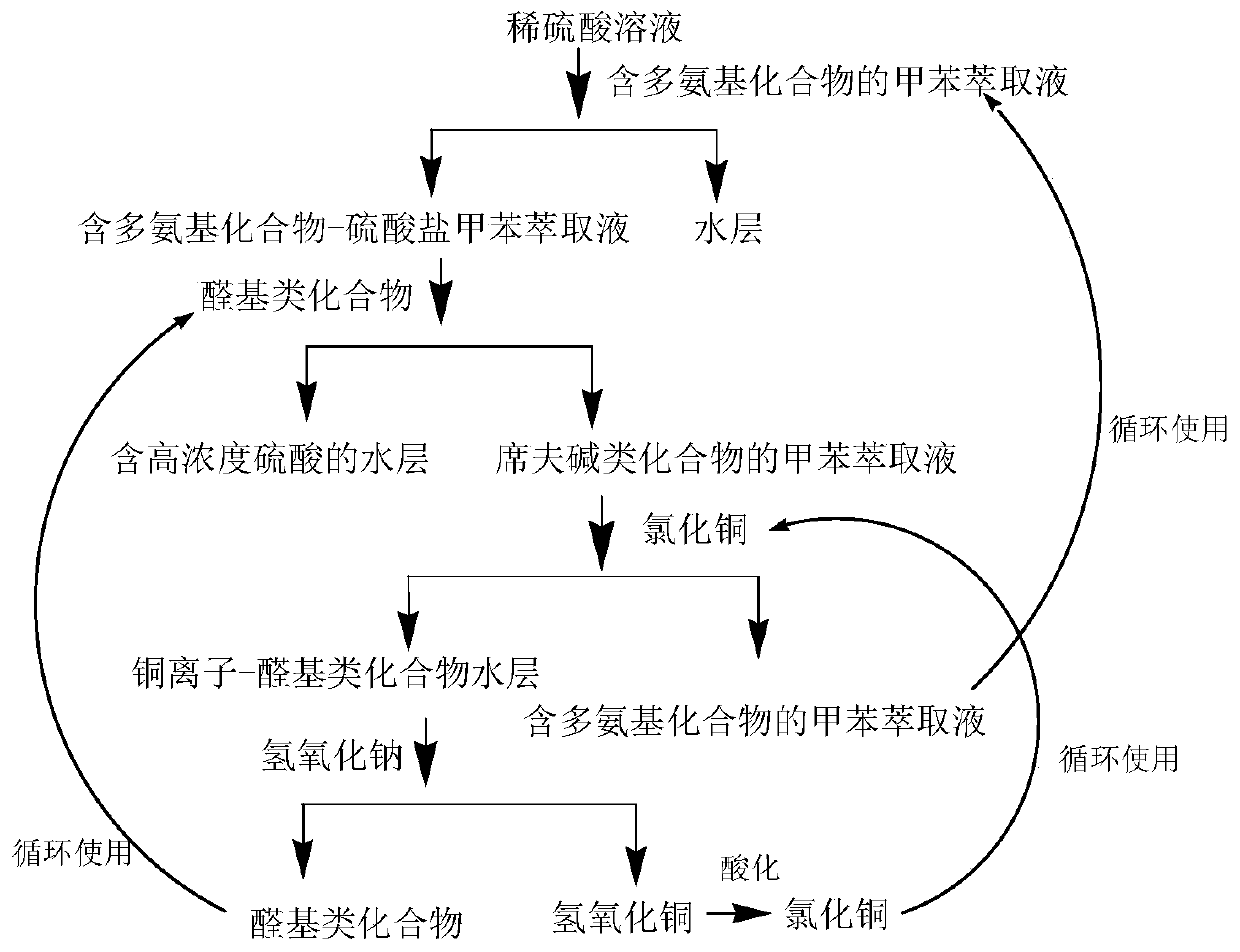

[0033] Such as figure 1 As shown, the recovery of dilute sulfuric acid in industrial wastewater is carried out according to the following steps:

[0034] Step 1: Get 1.0L of industrial wastewater with dilute sulfuric acid, wherein the mass content of sulfuric acid is about 1.0%, then add 0.4L of toluene extract containing polyamino compounds, wherein the weight content of polyamino compounds is 10.0%, fully After stirring and standing for 0.5 to 2.0 hours, separate the toluene extract;

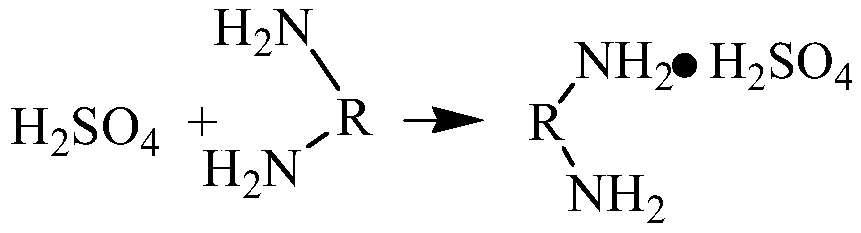

[0035] Equation 1 below, using -NH 2 Stronger dissolving ability dissolves sulfuric acid molecules into the toluene extract containing polyamino compounds, and separates after extraction:

[0036]

[0037] Equation 1 Reaction mechanism of sulfuric acid and polyamino compounds

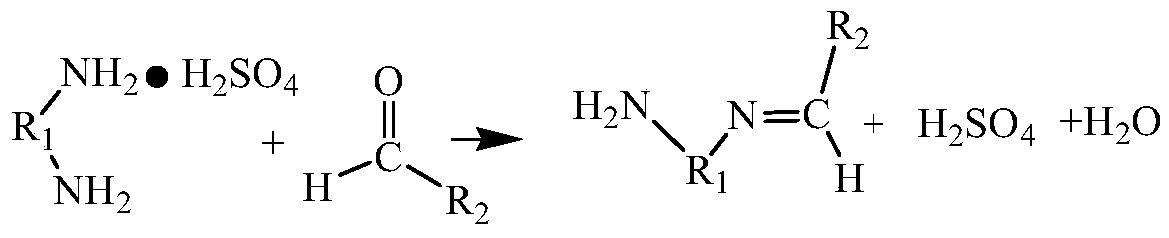

[0038] Step 2: Add aldehyde-based compounds and deionized water to the separated toluene extract, add 20.0 grams of aldehyde-based compounds per liter of the isolated toluene extract, and add 20.0 grams of aldehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com