Grinding cloth wheel

A technology of abrasive cloth wheel and abrasive cloth sheet, which is applied in the field of grinding and polishing processing tools, can solve the problems of flying chip grinding rate, abrasive cloth wheel fragmentation, low and other problems, and achieves the improvement of grinding rate, reduction of fragmentation and strong use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

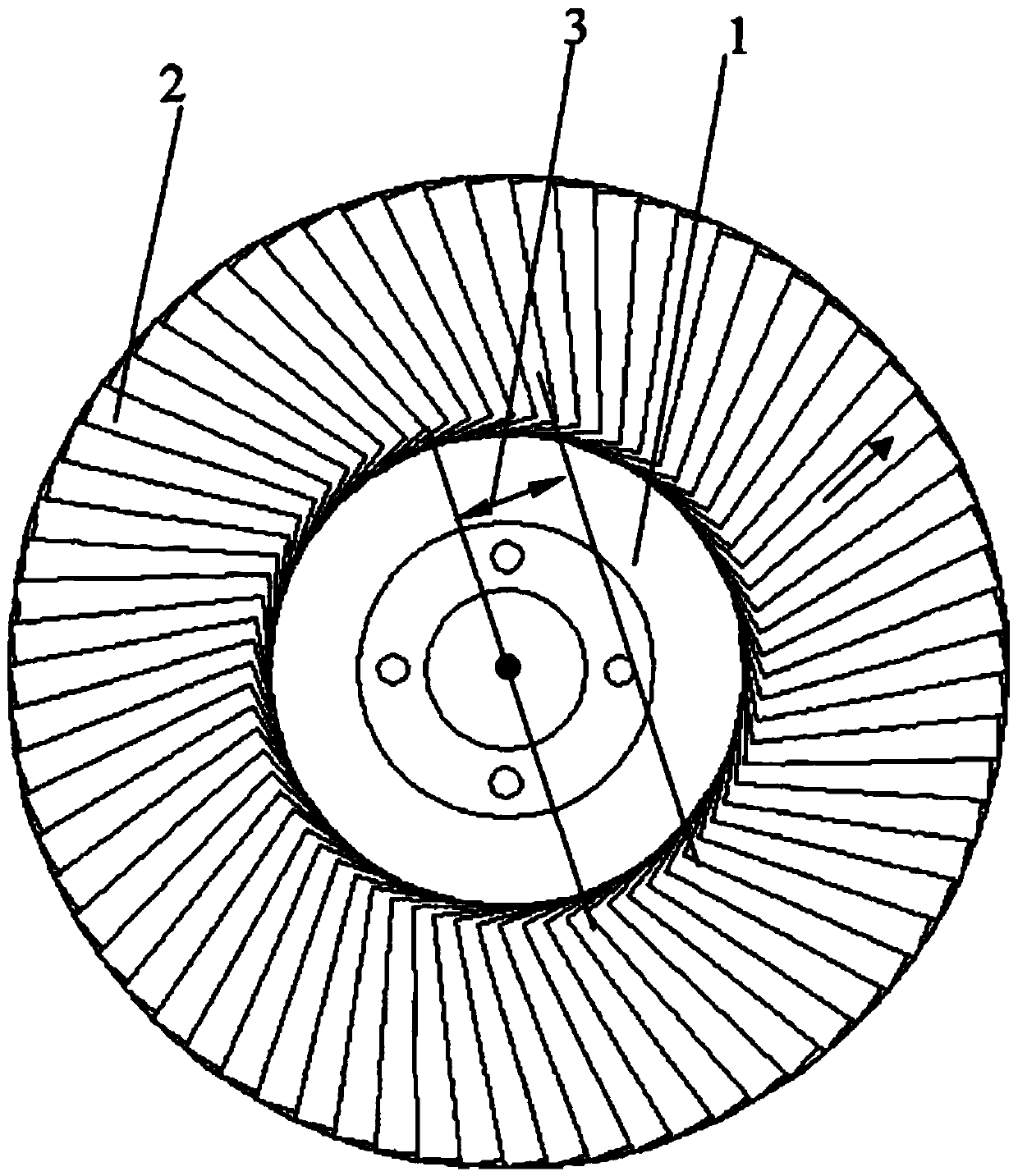

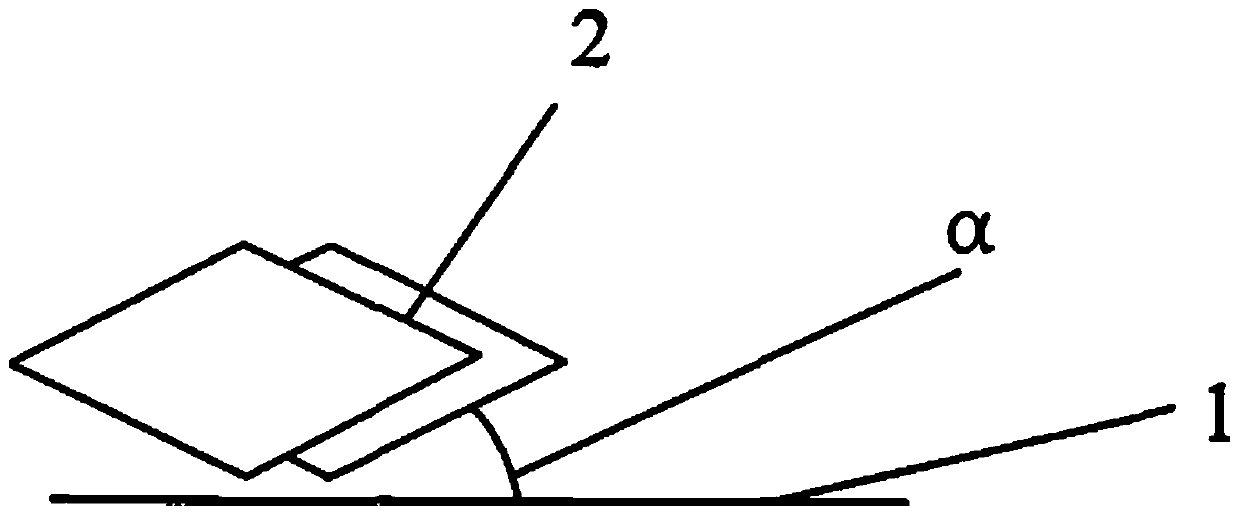

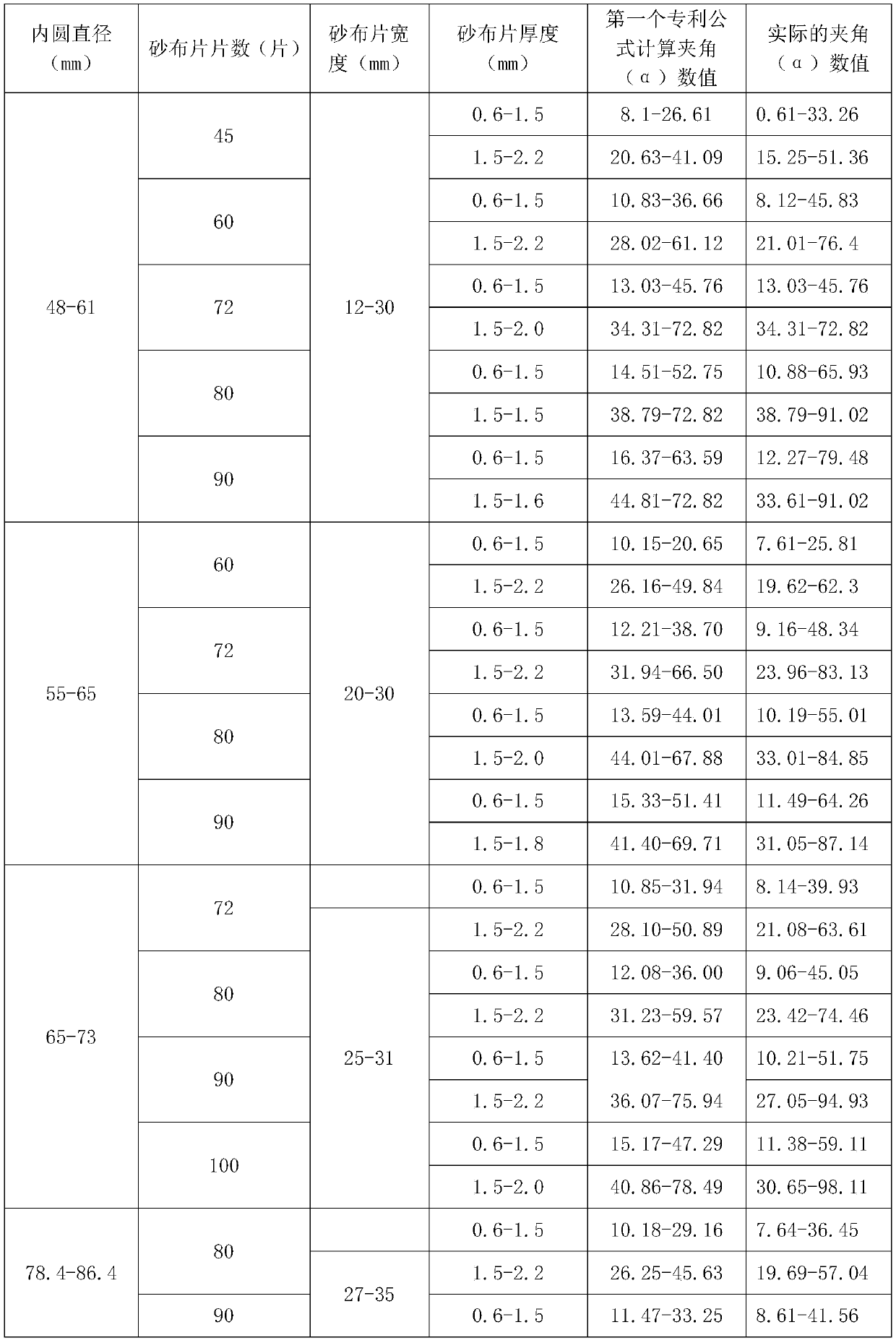

[0026] Such as Figure 1-2 As shown, a kind of emery cloth wheel, comprises carrier 1 and the emery cloth sheet 2 that is attached on the carrier, the included angle α of described emery cloth sheet and the plane where carrier is located meets following formula:

[0027] Sinα=(1+k)(D*N / 2πR), k∈[-0.2,-0.3]∪[0.2,0.3], where D is the thickness of a single emery cloth sheet, and N is the attachment on the plane grinding wheel The total number of abrasive cloth wheels, R is the radius of the inner circle of the flat abrasive cloth wheel, and k is the correction factor.

[0028] The emery cloth sheets are arranged along the inner circle of the plane emery cloth wheel, and the emery cloth wheels are successively overlapped on the circumference of the inner circle.

[0029] The side of the grinding wheel sheet is not collinear with the radial direction of the circular carrier.

[0030] The center of the emery cloth sheet carrier is provided with a fixed ring, the fixed ring includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com