Polycrystal string belt template of solar energy photovoltaic cell

A photovoltaic cell and solar energy technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as short circuit and difficulty in ensuring the appearance of components, so as to reduce production costs, avoid short circuits, and reduce economic losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

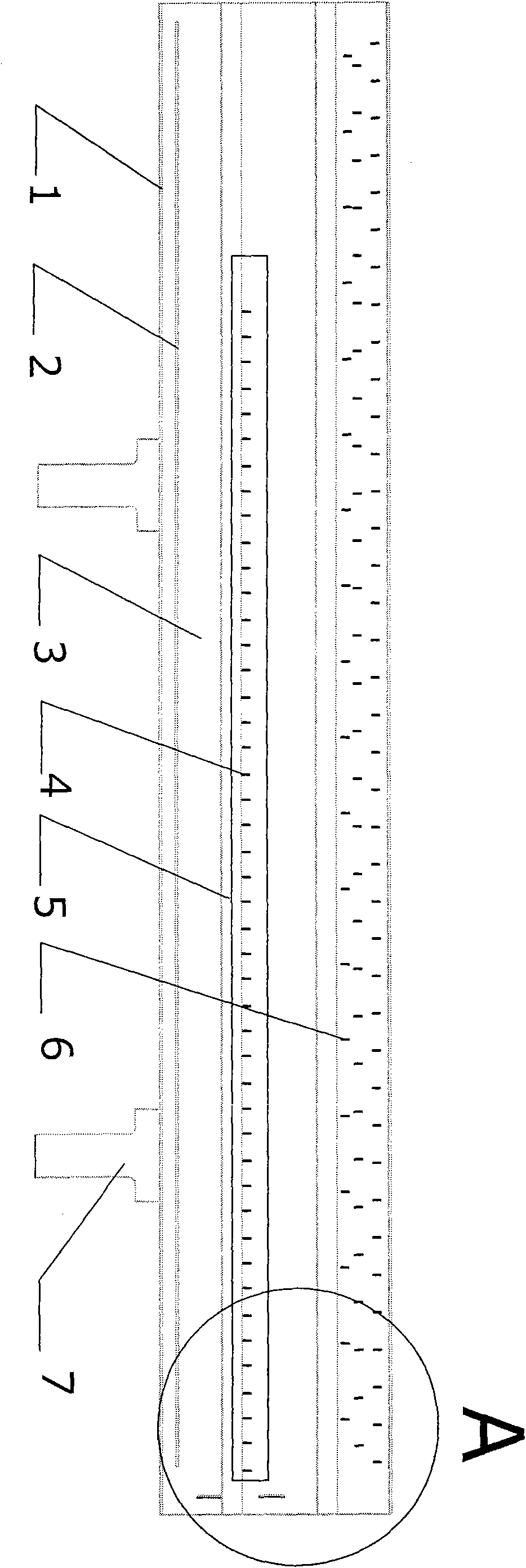

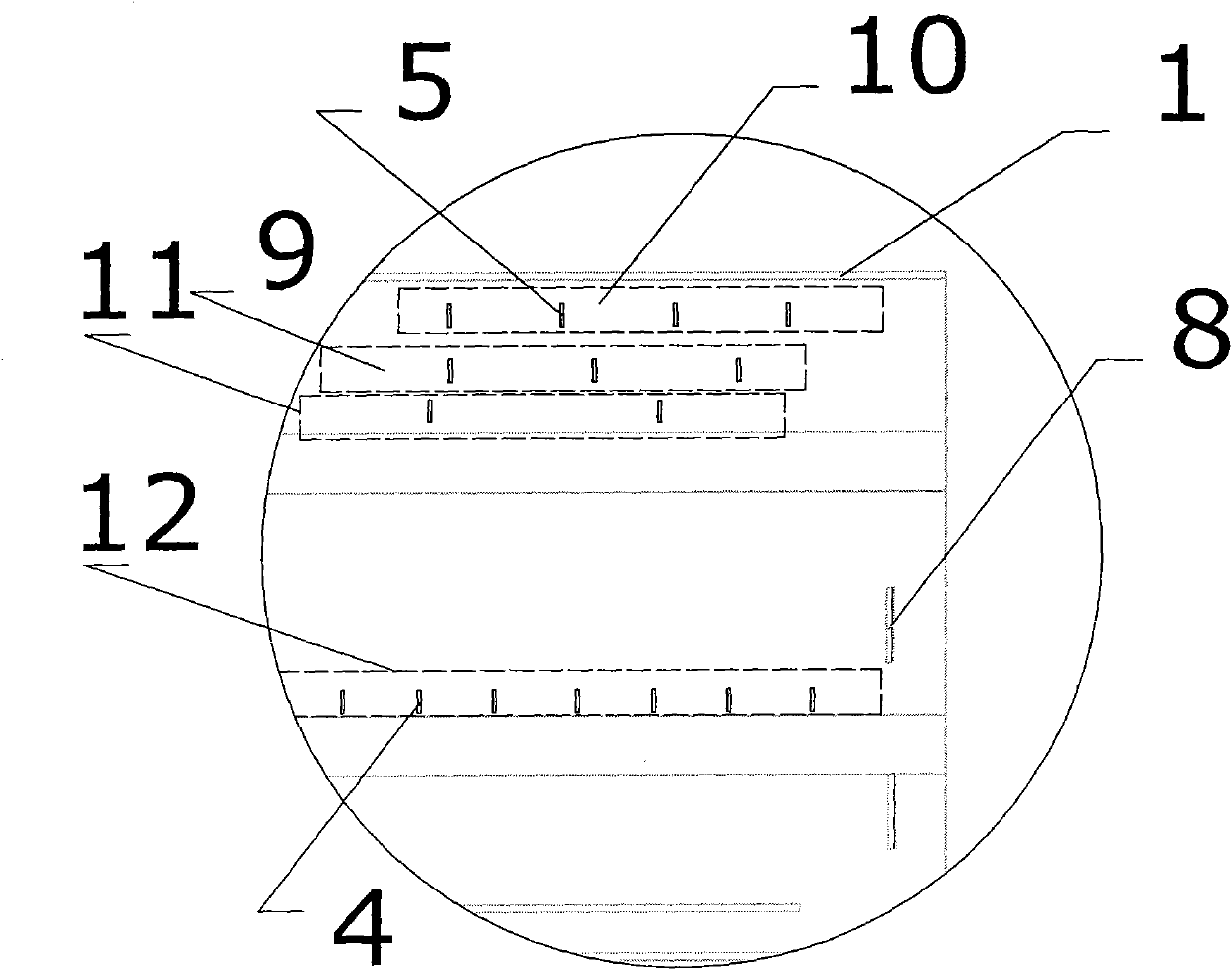

[0020] See attached figure 1 , 2 3. The solar photovoltaic cell polycrystalline string template shown in the embodiment of the present invention is all made of an aluminum alloy material with a hardness ≥ 10HW after hardening treatment. It is a top side with a baffle plate 2 corresponding to the welding ribbon. The flat plate 3 with the groove 5 has multiple groups of arrangement areas 9, 10, 11, 12 formed by a plurality of slots 6 opened on the flat plate. Corresponding to 1 / 6, 2 / 6...5 / 6 slices is arrangement area 9, corresponding to 1 / 9, 2 / 9...8 / 9 slices is arrangement area 10, corresponding to 1 / 4, 2 / 4, 3 / 4 slices are the arrangement area 11, corresponding to 1 / 13, 2 / 13...12 / 13 slices, 1 / 26, 2 / 26...25 / 26 slices are the arrangement area 12. In different arrangement areas on the flat plate, the transverse gaps between the slots are respectively equal to the width setting values of the polycrystalline small component cells of different specifications. In the same arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com