Weather-proof insulating power cable

A power cable and weather-resistant technology, which is applied in the direction of insulated cables, power cables, insulated conductors, etc., can solve the problem of affecting the normal operation and drawing accuracy of the inner conductor raw material cable, the extruder does not have the function of breaking the cable material, and mixed solid particles, etc. Problems, to achieve the effect of improving the effect of melt extrusion, improving the quality of cables, and good quality accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

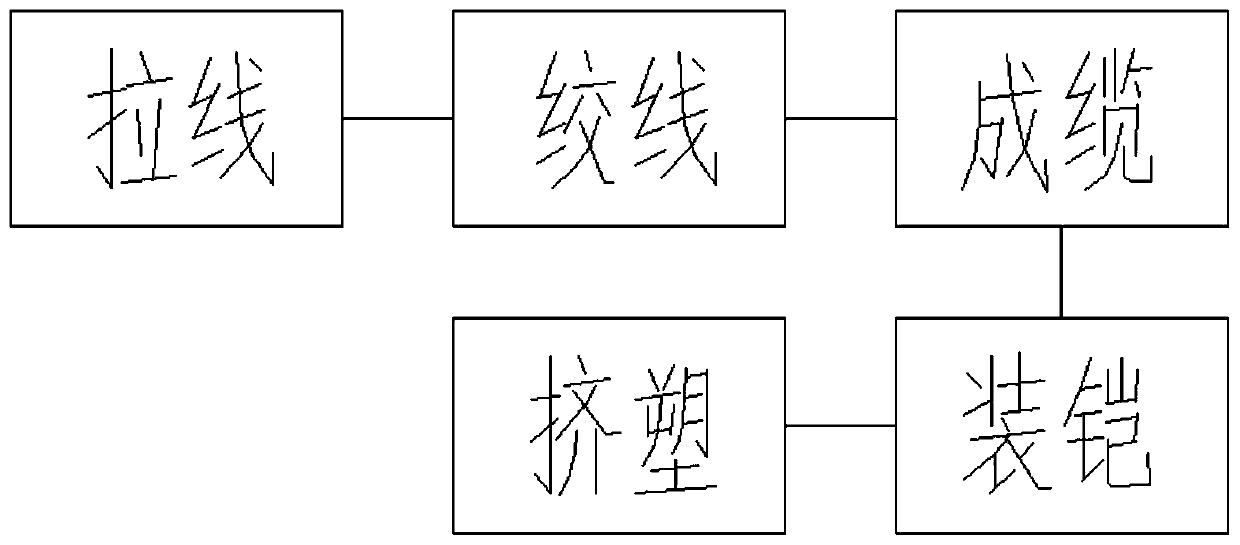

[0061] A weather-resistant insulated power cable is characterized in that its production steps include drawing wires, twisting wires, cabling, armoring and extrusion, and the production steps include the following specific contents:

[0062] (1) Wire drawing: send the inner conductor raw material cable to the wire drawing device for wire drawing, and draw the conductor wire with specified specifications;

[0063] (2) Stranded wires: The conductor wires obtained in step (1) are stranded by the non-back twisting method. When twisting the wires, the outer conductor wires are wound in the right direction (Z shape), and the inner layer conductor wires are wound in the left direction. Winding (S-shape), twisted into a conductor core, and then compressed;

[0064] (3) Cabling: After the twisting is completed, the conductor core is obtained, and the conductor core is sent to the cable forming machine for cable formation. After the cabling is completed, the quality inspection is carri...

Embodiment 2

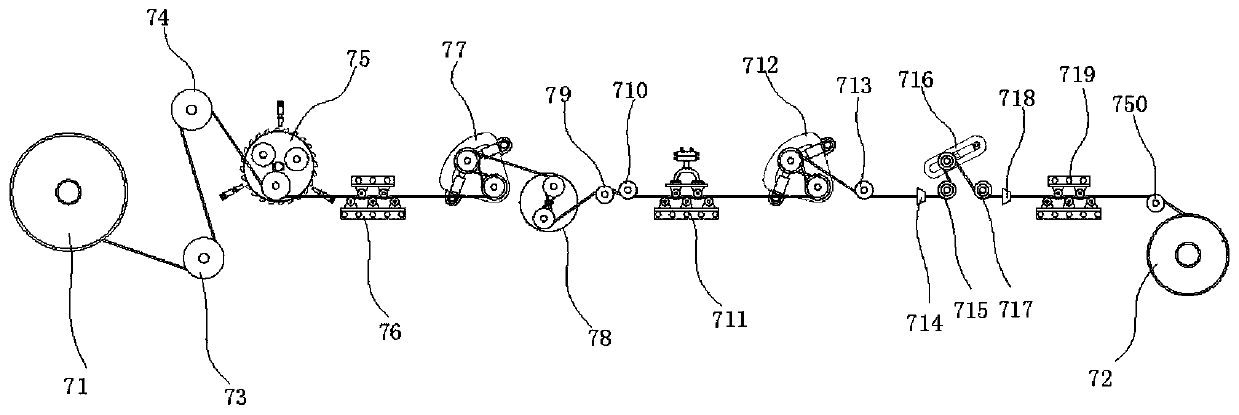

[0068] The wire drawing device comprises a pay-off roller 71 and a take-up roller 72, between which the pay-off roller 71 and the take-up roller 72 are successively provided with a first guide roller 73, a second guide roller 74, a primary wire drawing mechanism 75, a first Guide assembly 76, secondary wire drawing mechanism 77, tertiary wire drawing mechanism 78, third guide roller 79, fourth guide roller 710, movable guide assembly 711, fourth wire drawing mechanism 712, fifth guide roller 713, first wire drawing die 714, The sixth guide roller 715 , the movable guide roller assembly 716 , the seventh guide roller 717 , the second drawing die 718 , the second guide assembly 719 and the eighth guide roller 750 .

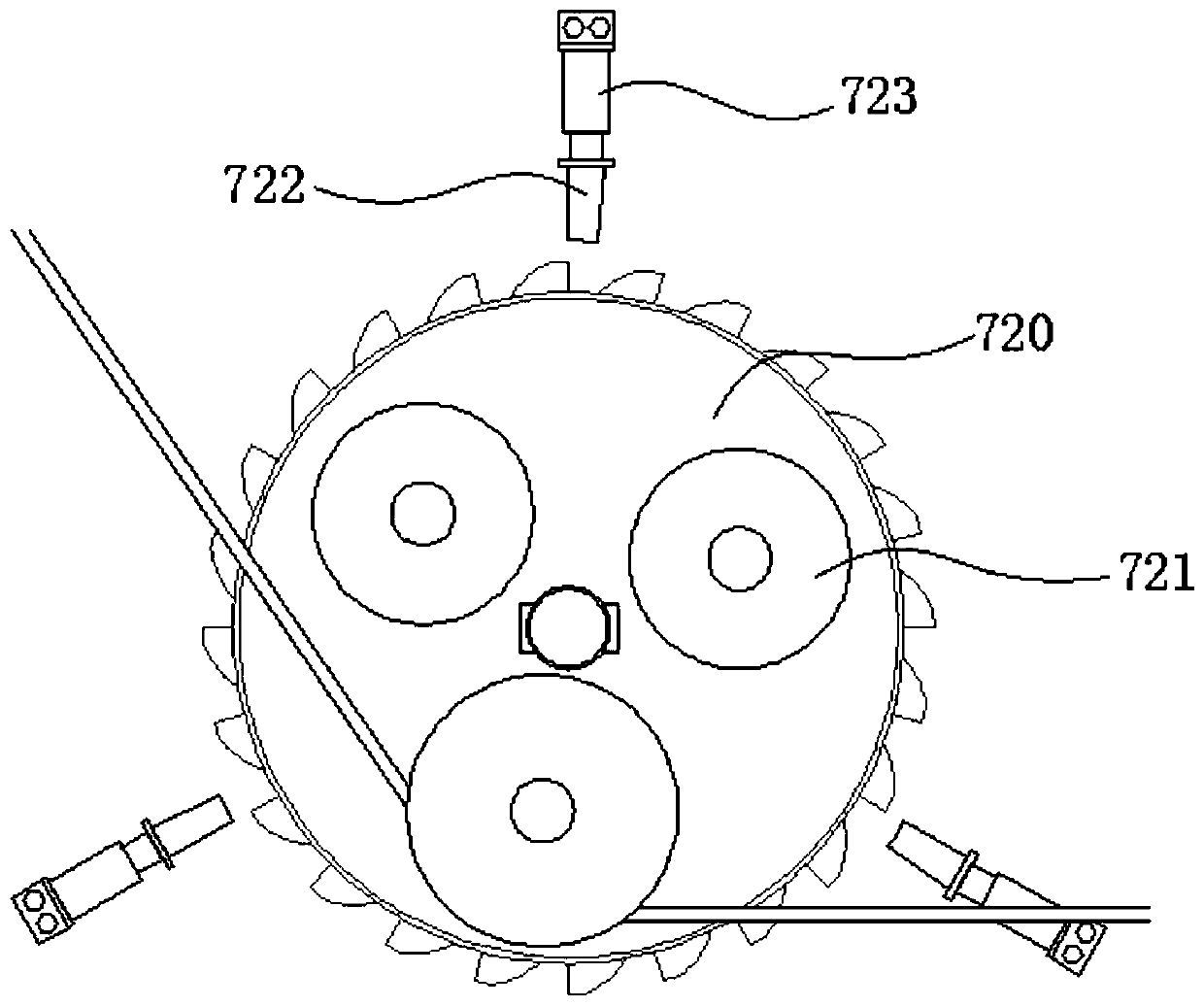

[0069] Wherein, the first guide roller 73 and the second guide roller 74 are distributed up and down, the primary drawing mechanism 75 includes a first rotating panel 720, a primary drawing roller 721 and a pawl 722, and the first rotating panel 720 is circular shap...

Embodiment 3

[0083] The drawing device described in embodiment two, its working method is as follows:

[0084] (a1) The inner conductor material cable is unwound by the pay-off roller 71, first bypassing the first guide roller 73 and the second guide roller 74, so that the inner conductor material cable is stretched in a broken line;

[0085](a 2) Subsequently, the inner conductor raw material cable bypasses the primary wire drawing roller 721 on the primary wire drawing mechanism 75 to perform the first wire drawing. Road, adjust the drawing specifications;

[0086] (a 3) After the inner conductor raw material cables that have been drawn for the first time are guided by the first guide assembly 76, they enter the secondary wire drawing mechanism 77. The wire drawing rollers 728 are wound in a shape of 78 for the second wire drawing;

[0087] (a 4) The inner conductor raw material cable that has completed the second wire drawing enters the third wire drawing mechanism 78, and the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com