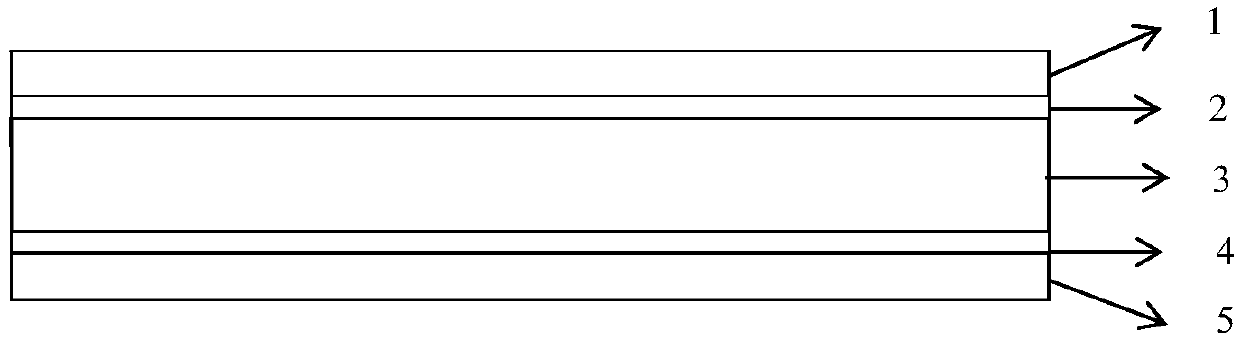

Novel UV cross-linked cured multi-layer optical adhesive film and application thereof

A technology of cross-linking curing and optical glue, which is applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc. It can solve the problems of insufficient processing performance, high lamination requirements, and narrow application range, etc., to achieve Good spatial extensibility, avoiding glue overflow, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Adhesive film raw material by weight:

[0029] The non-adhesive layer is 90 parts of EVA (melt index is 24) resin, 10 parts of polybutene, 0.1 part of photoinitiator 1-hydroxycyclohexyl phenyl ketone, 0.2 part of antioxidant 168, and 0.1 part of light stabilizer 770 share;

[0030] Both the thickness of the first adhesive layer and the second adhesive layer are 10 μm, and the ingredients are the same, 60 parts of polyurethane acrylate, 20 parts of isooctyl acrylate, 15 parts of isobornyl methacrylate, and 4 parts of 1-hydroxycyclohexyl phenyl ketone , phenyl bis(2,4,6-trimethylbenzoyl) phosphorus oxide 1, 0.2 part of antioxidant 168, 0.1 part of light stabilizer 770;

[0031] The first release layer and the second release layer are PET films with release forces of 10 g and 30 g, respectively.

[0032] The prepared film is UV cured.

[0033] The prepared adhesive film has a light transmittance of over 90%, is easy to degas during the bonding process, and has excellent...

Embodiment 2

[0035] Adhesive film raw material by weight:

[0036] The non-adhesive layer is 80 parts of EVA (melt index 33) resin, 20 parts of polybutene, 0.5 part of benzoylformate photoinitiator, 0.1 part of antioxidant 1010, and 0.2 part of light stabilizer 571;

[0037] Both the thickness of the first adhesive layer and the second adhesive layer are 15 μm, and the ingredients are the same, 75 parts of polyolefin acrylate, 5 parts of 4-hydroxybutyl acrylate, 15 parts of isobornyl acrylate, and 5 parts of benzoylformate photoinitiator Parts, antioxidant 1010 is 0.1 part, light stabilizer 571 is 0.2 part;

[0038] The first release layer is a PET film with a thickness of 35 μm and a release force of 15 g, and the second release layer is a PE film with a thickness of 35 μm and a release force of 40 g.

[0039] The prepared film is UV cured.

[0040] The prepared adhesive film has a light transmittance of over 90%, is easy to defoam during the bonding process, and has excellent bonding p...

Embodiment 3

[0042] Adhesive film raw material by weight:

[0043] The non-adhesive layer is 80 parts of EVA (melt index 28) resin, 19 parts of polybutene, 0.1 part of 1-hydroxycyclohexyl phenyl ketone, phenyl bis(2,4,6-trimethylbenzoyl) oxidation 0.1 part of phosphorus, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.2 part of light stabilizer 571; the thickness of the first adhesive layer and the second adhesive layer are both 8 μm, the same composition, 75 parts of polyurethane acrylate , 10 parts of isobornyl methacrylate, 10 parts of lauryl acrylate, 4 parts of 1-hydroxycyclohexyl phenyl ketone, phenyl bis(2,4,6-trimethylbenzoyl) phosphorus oxide 1 part, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.2 part of light stabilizer 571;

[0044] The first release layer and the second release layer are 50 μm PET films with release forces of 12 g and 35 g, respectively.

[0045] The prepared film is UV cured.

[0046] The prepared adhesive film has a light trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com