A kind of agar production process

A production process, agar technology, applied in the field of agar production process, can solve the problems of cumbersome agar production process, time-consuming and labor-intensive process, increase production cost, etc., and achieve the effect of saving manpower and material resources, reducing operation steps and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

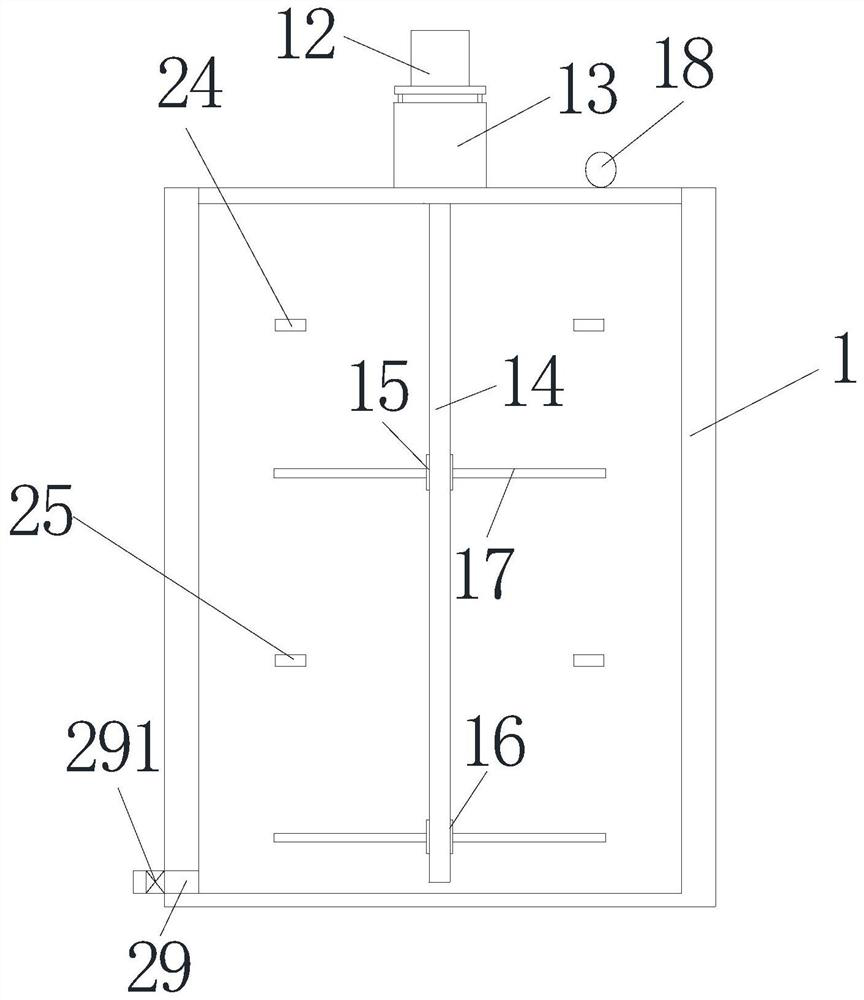

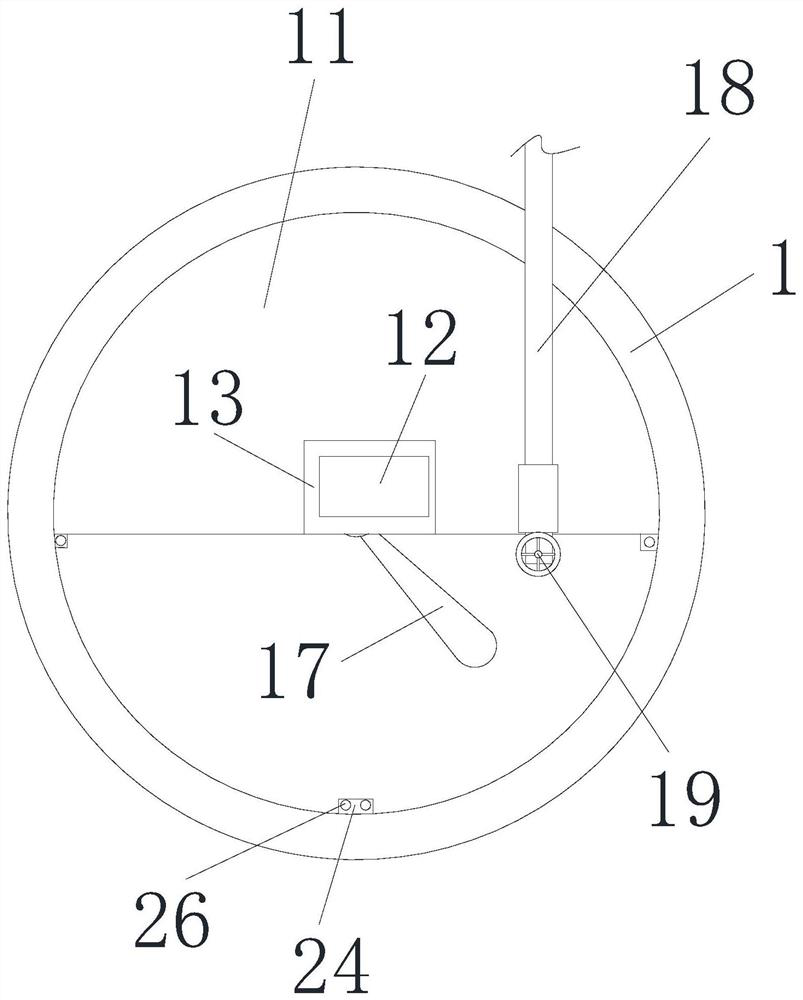

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

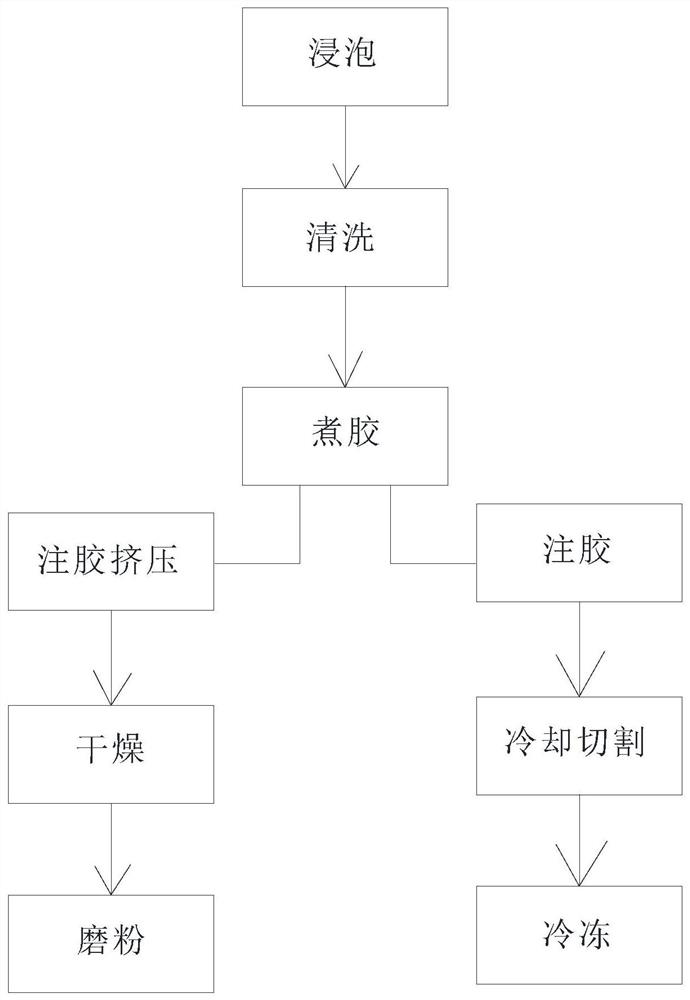

[0053] see Figure 1 to Figure 16 Shown, the present invention provides an embodiment: a kind of agar production technique comprises the following steps:

[0054] Step S1: Pour 1 / 3 of the water into the cleaning and soaking device, and add sodium hydroxide to the water, put the ivy in the cleaning and soaking device, and soak it; the addition ratio of sodium hydroxide is Twice of that, when adding 1 ton of raw watermelon to the cleaning and soaking device, it is necessary to add 2 tons of sodium hydroxide; Sodium, and so on.

[0055] Step S2, after soaking, discharge the soaked water out of the cleaning and soaking device, and recycle and store it for next use; transport the clean water to the cleaning and soaking device, stir and clean the sage, and then discharge the water after stirring and cleaning. Clean and soak the device as described above, repeat the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com