Preparation method of alkyl polyglycoside by using sulphonating graphene as catalyst

A technology of sulfonated graphene and alkyl glycosides, which is applied in the direction of physical/chemical process catalysts, preparation of sugar derivatives, chemical instruments and methods, etc., can solve the problems of incomplete conversion and high production costs, and achieve stable product properties and catalytic The effect of short time and high catalytic yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of p-aminobenzenesulfonic acid diazonium salt: p-aminobenzenesulfonic acid and sodium nitrite were dissolved in hydrochloric acid solution, and the p-aminobenzenesulfonic acid diazonium salt was prepared under the condition of ice bath cooling.

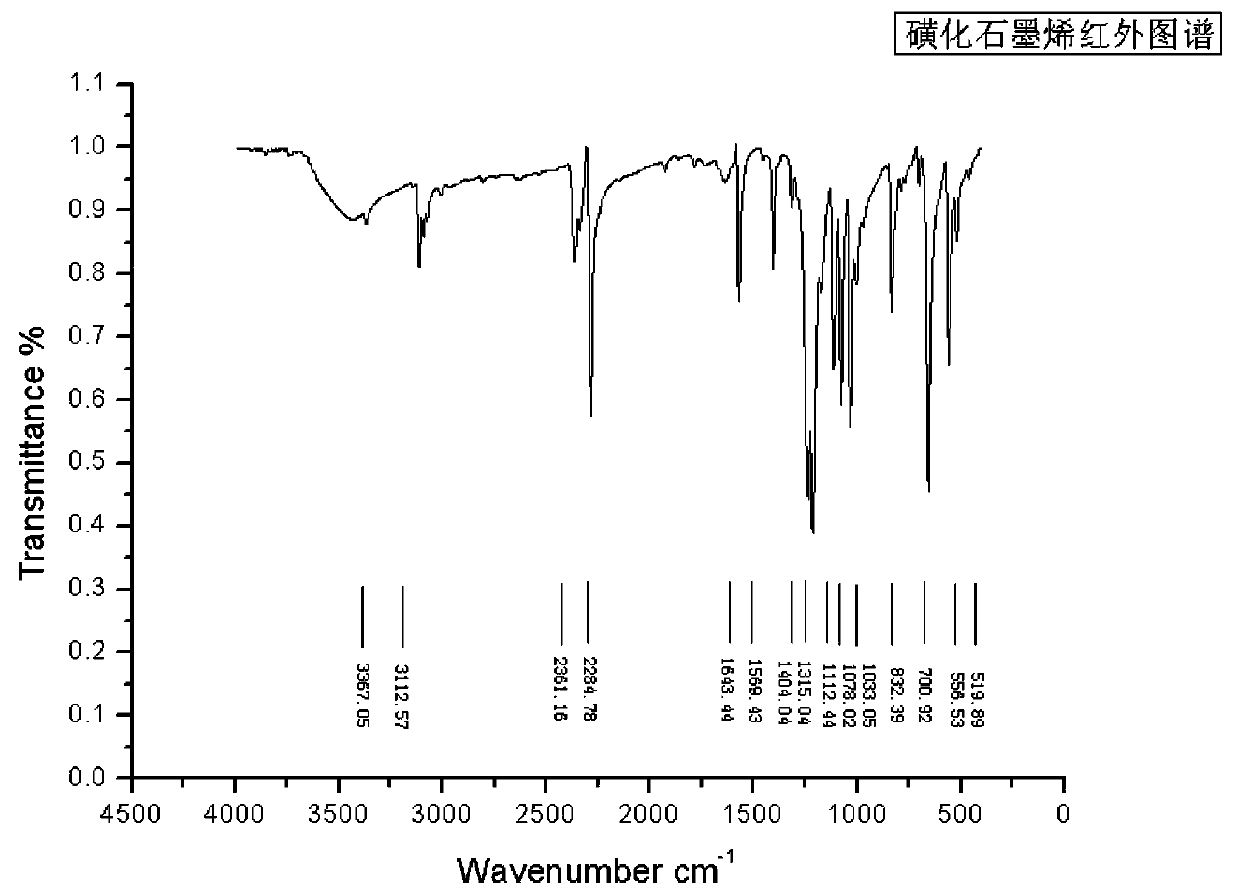

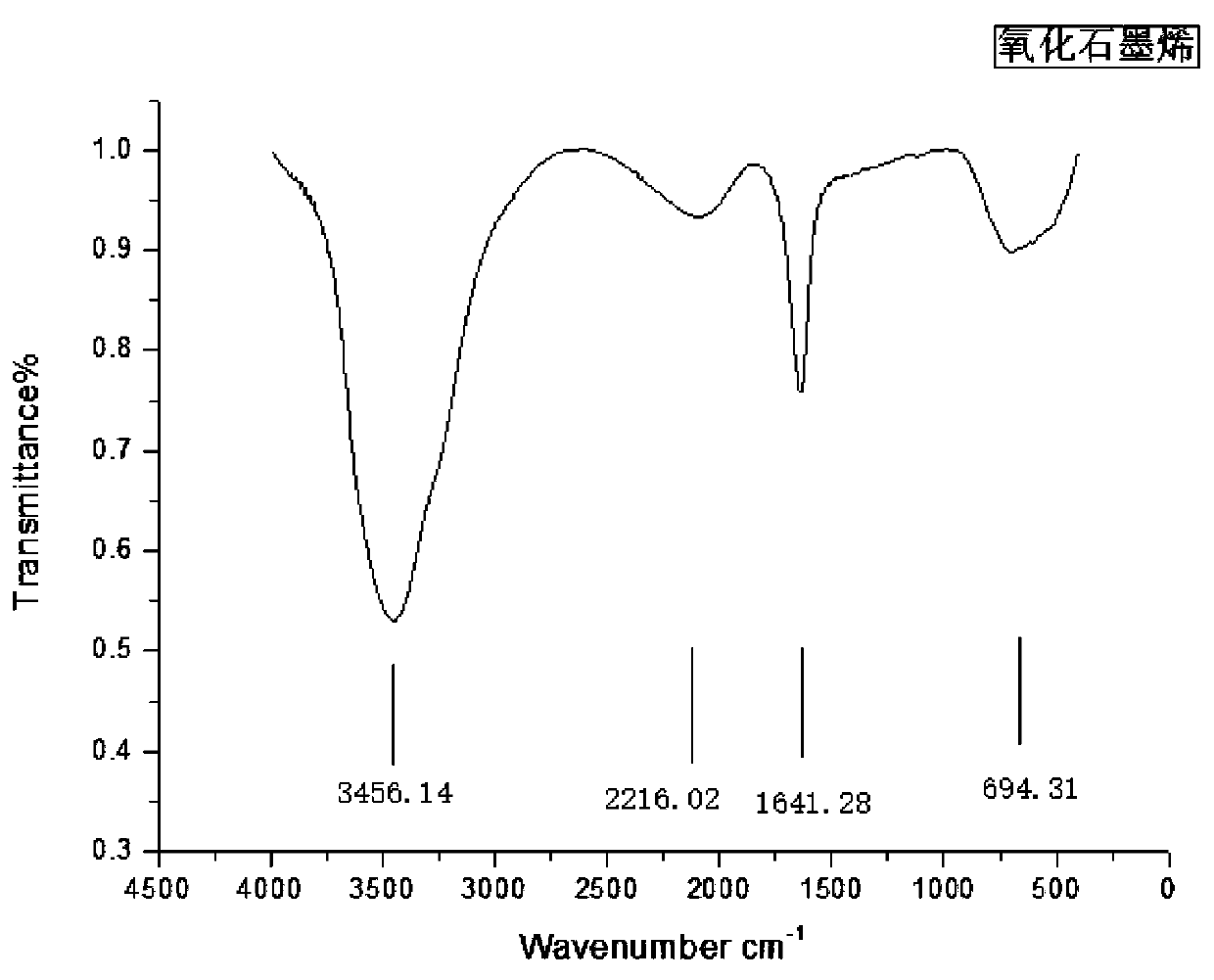

[0021] (2) Sulfonation of graphene oxide: Dissolve 1.35 g of diazonium salt of p-aminobenzenesulfonic acid in 10 mL of twice distilled water, and slowly add the solution dropwise to 13 mL of 1 mg / mL graphene oxide (see figure 2 ) suspension, ice-bathed, and vigorously stirred for 6 hours; filtered and washed with water until neutral, and vacuum-dried to obtain a sulfonated graphene catalyst. Infrared spectrum see figure 1 .

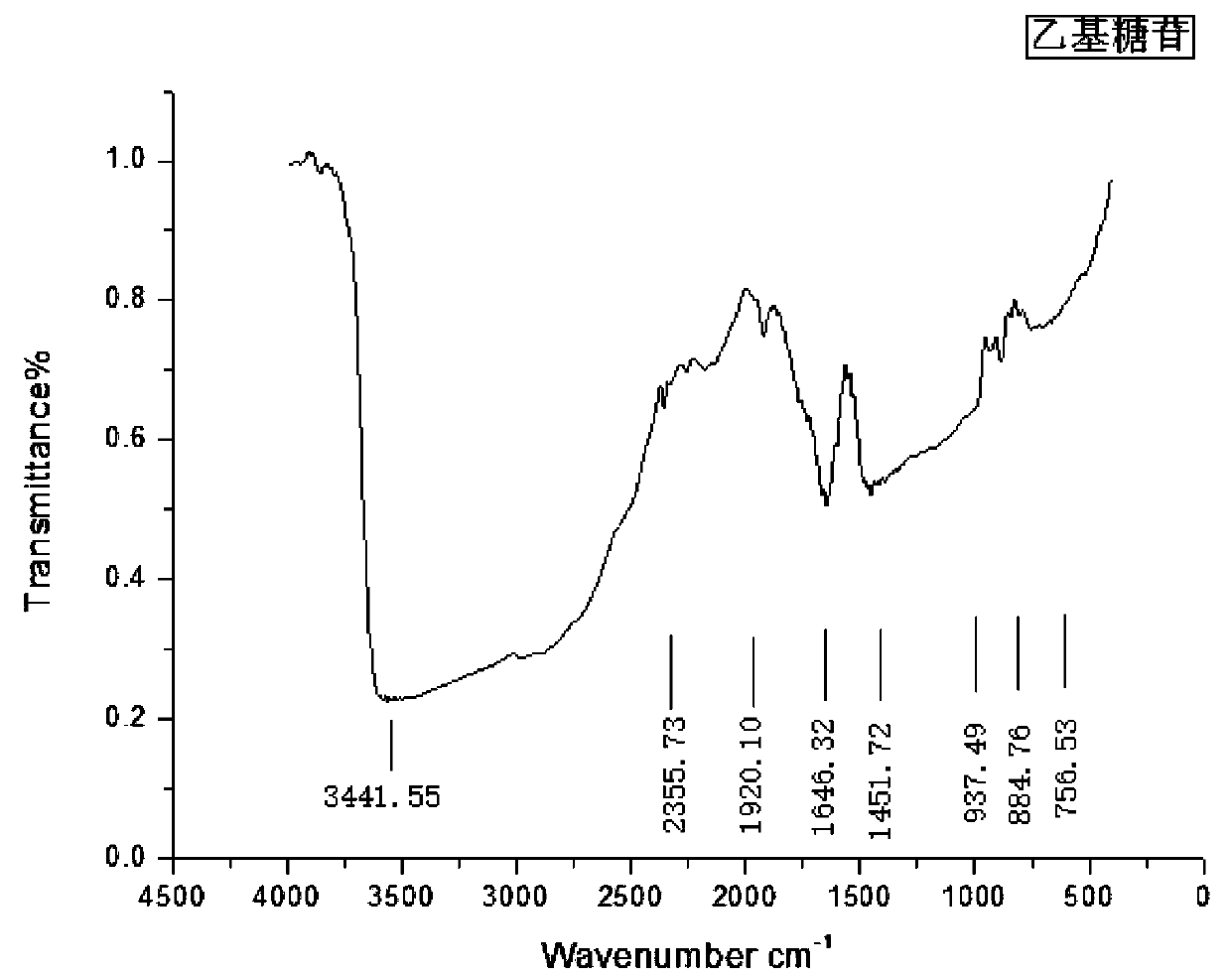

[0022] (3) Add 3g of anhydrous glucose into a three-necked flask with a stirrer (see image 3 ), 18g of ethanol, preheated at 80°C and refluxed for 20min, added 0.3g of sulfonated graphene, and continued to reflux at 155°C for 30min with heating and stirring.

[0023] (4) Heat filtratio...

Embodiment 2

[0025] Add 3 g of anhydrous glucose and 15 g of lauryl alcohol into a three-necked flask with a stirrer, preheat to reflux at 80°C for 20 minutes, add 0.3 g of sulfonated graphene, and continue heating and stirring at reflux at 140°C for 30 minutes. After the reaction, the sulfonated graphene was removed by filtration, and the filtrate was distilled under reduced pressure to obtain a light yellow syrupy product with a product yield of 97%. All the other are with embodiment 1.

Embodiment 3

[0027] Add 3 g of anhydrous glucose and 12 g of lauryl alcohol into a three-necked flask with a stirrer, preheat to reflux at 80°C for 20 minutes, add 0.3 g of sulfonated graphene, and continue heating and stirring at reflux at 170°C for 30 minutes. After the reaction, the sulfonated graphene was removed by filtration, and the filtrate was distilled under reduced pressure to obtain a light yellow syrupy product with a product yield of 97%. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com