Welding measuring device and welding method

A measuring device and welding method technology, applied in the field of welding, can solve problems such as the inability to meet the needs of changing monitoring points at any time, difficulty in completing armored thermocouples, and inaccurate temperature measurement, so as to avoid glue residue, realize real-time comparison, Avoid the effect of degaussing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

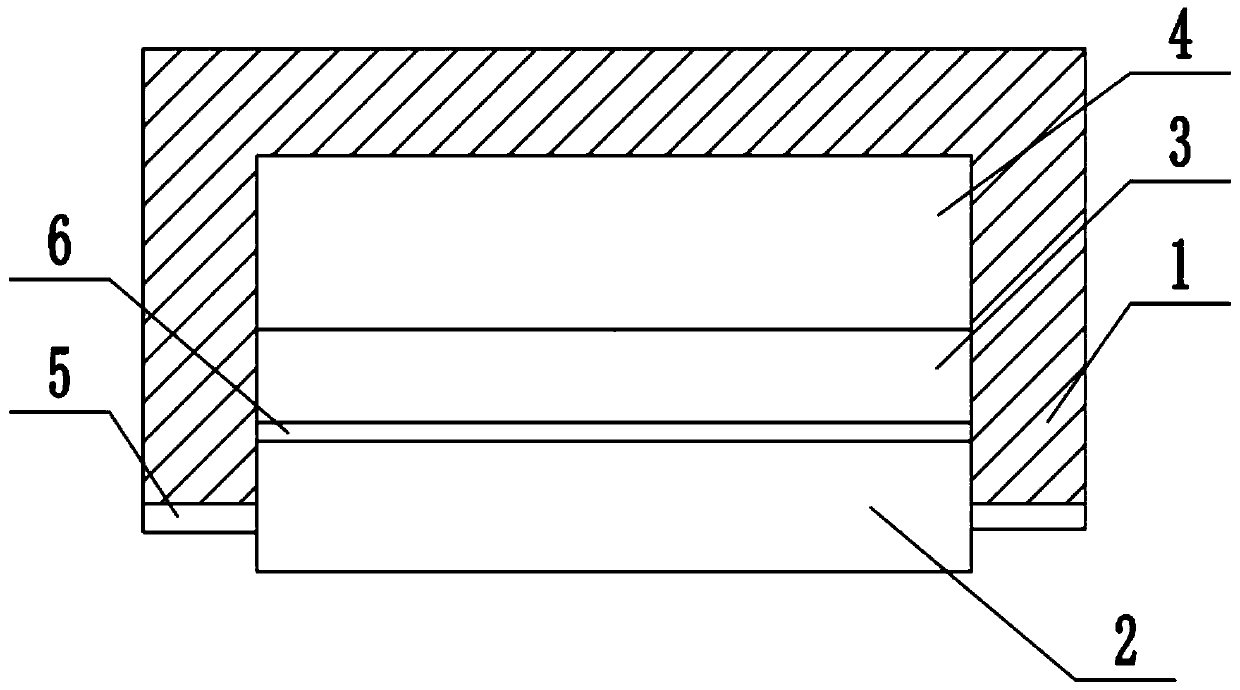

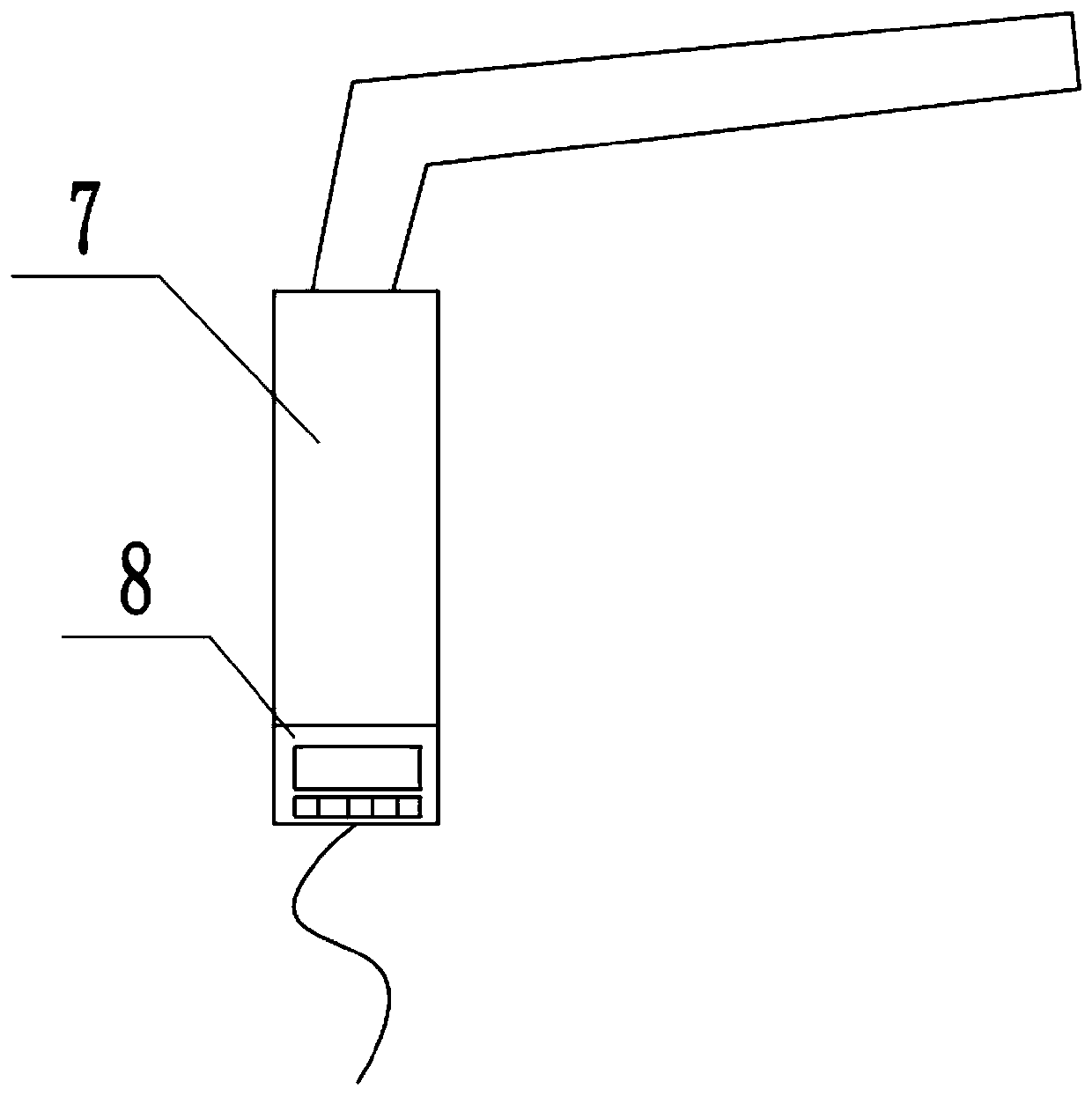

[0037] In a typical implementation of the present application, such as figure 1 , figure 2 As shown, a temperature measurement device for high-altitude equipment welding in thermal power plants is proposed.

[0038] It includes a receiving terminal 8 and a plurality of temperature measuring bodies, the temperature measuring body includes a magnetic housing 1, the magnetic housing includes an open cavity, and a power supply module 4 and a processor connected in sequence are arranged in the cavity 3 and the temperature measurement module 2, the temperature measurement module part is located outside the cavity, the magnetic shell is used to fix the temperature measurement module on the object to be measured by magnetic force, and there is a gap between the magnetic shell and the object to be measured, The processor acquires the data of the temperature measurement module and sends it to the receiving terminal for display, so as to obtain the temperature of the weldment measureme...

Embodiment 2

[0051] In another typical embodiment of the present application, a welding method assisted by the above-mentioned temperature measuring device is provided.

[0052] Include the following steps:

[0053] Adsorb several temperature measuring bodies evenly on both sides of the area to be welded;

[0054] Obtain the real-time temperature of the welding area through the temperature of the temperature measuring body during the pre-welding preheating process;

[0055] When the temperature measuring body measures that the welding area has reached the target temperature, stop preheating and weld the weld seam;

[0056] After the welding is completed, remove the multiple temperature measuring bodies located in the welding area and adsorb them on the weld to obtain the real-time temperature of the weld. When measuring the temperature of the weld, keep multiple temperature measuring bodies in the non-weld seam within the area of the location;

[0057] When the temperature of the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com