Vibration absorber

An absorber, mesh sleeve technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as cracks in bellows, defective products, etc., to achieve good support strength, long service life, and avoid welding. crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention will be further described:

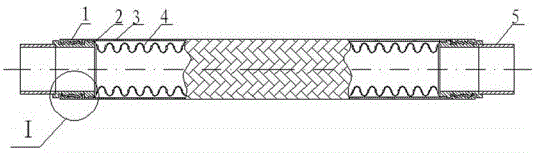

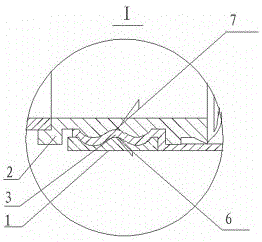

[0010] The shock absorber includes a bellows 4, a stainless steel net sleeve 3, two inner clamp tubes 2 of the net sleeve, two outer clamp tubes 1 of the net sleeve, and two outer pipe joints 5. The two inner clamping tubes 2 of the mesh sleeves are respectively welded to the two ends of the bellows 4, the bellows 4 and the inner clamping tubes 2 of the two mesh sleeves are covered with a stainless steel mesh sleeve 3, and the outer clamping tubes of the two mesh sleeves 1 and respectively corresponding outer jackets on the two inner clamping tubes 2 of the net sleeves, so that the two ends of the stainless steel net sleeves 3 are placed between the outer clamping tubes 1 of the net sleeves and the inner clamping tubes 2 of the net sleeves. The outer diameter of the inner pinch tube 2 of the net sleeve is provided with annular grooves 7 of different depths and widths, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com