Hardfacing process

A process and electrode technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of easy cracking, affecting product quality, affecting the service life of water spray desuperheaters, etc., to avoid welding cracks, the process is simple, Ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

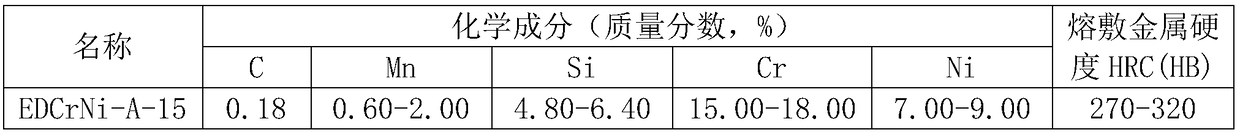

[0022] This embodiment studies on the low-alloy heat-resistant steel 12Cr1MoVG, surfacing wear-resistant fusion welding metal EDCrNi-A-15 (D547) new technology, the main chemical composition (mass fraction, %) of the low-alloy heat-resistant steel 12Cr1MoVG pipe is as follows Show:

[0023] C: 0.08-0.15

[0024] Mn: 0.40-0.70

[0025] Si: 0.17-0.37

[0026] P: ≤0.03

[0027] S: ≤0.03

[0028] Cr: 0.90-1.20

[0029] Mo: 0.25-0.35

[0030] V: 0.15-0.30

[0031] Cu: ≤0.20

[0032] 1. Pre-welding preparations, choose Jinglei welding consumables with an outer diameter of 4.0mm and a brand of GEH-547 (D547) welding rods. The composition and performance of the welding consumables meet the standard requirements of EDCrNi-A-15 in GB / T984. The wear-resistant welding metal for surfacing welding is EDCrNi-A-15 (D547);

[0033]

[0034] 2. Remove water, rust, oil stains and other impurities on the surface to be surfacing until the metallic luster is exposed;

[0035] 3. Prehea...

Embodiment 2

[0038] This embodiment studies on the low-alloy heat-resistant steel 12Cr1MoVG, surfacing wear-resistant fusion welding metal EDCrNi-A-15 (D547) new technology, the main chemical composition (mass fraction, %) of the low-alloy heat-resistant steel 12Cr1MoVG pipe is as follows Show:

[0039] C: 0.08-0.15

[0040] Mn: 0.40-0.70

[0041] Si: 0.17-0.37

[0042] P: ≤0.03

[0043] S: ≤0.03

[0044] Cr: 0.90-1.20

[0045] Mo: 0.25-0.35

[0046] V: 0.15-0.30

[0047] Cu: ≤0.20

[0048] 1. Pre-welding preparations, choose Jinglei welding consumables with an outer diameter of 4.0mm and a brand of GEH-547 (D547) welding rods. The composition and performance of the welding consumables meet the standard requirements of EDCrNi-A-15 in GB / T984. The wear-resistant welding metal for surfacing welding is EDCrNi-A-15 (D547);

[0049]

[0050] 2. Remove water, rust, oil stains and other impurities on the surface to be surfacing until the metallic luster is exposed;

[0051] 3. Prehea...

Embodiment 3

[0054] This embodiment studies on the low-alloy heat-resistant steel 12Cr1MoVG, surfacing wear-resistant fusion welding metal EDCrNi-A-15 (D547) new technology, the main chemical composition (mass fraction, %) of the low-alloy heat-resistant steel 12Cr1MoVG pipe is as follows Show:

[0055] C: 0.08-0.15

[0056] Mn: 0.40-0.70

[0057] Si: 0.17-0.37

[0058] P: ≤0.03

[0059] S: ≤0.03

[0060] Cr: 0.90-1.20

[0061] Mo: 0.25-0.35

[0062] V: 0.15-0.30

[0063] Cu: ≤0.20

[0064] 1. Pre-welding preparations, choose Jinglei welding consumables with an outer diameter of 4.0mm and a brand of GEH-547 (D547) welding rods. The composition and performance of the welding consumables meet the standard requirements of EDCrNi-A-15 in GB / T984. The wear-resistant welding metal for surfacing welding is EDCrNi-A-15 (D547);

[0065]

[0066] 2. Remove water, rust, oil stains and other impurities on the surface to be surfacing until the metallic luster is exposed;

[0067] 3. Prehea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com