Light-emitting backlight source of single-interlink circular convex surface cathode multi-swallow-wing-arc gating structure

A raised surface, backlight technology, applied in solid cathode, cold cathode tube, cold cathode manufacturing and other directions, can solve the problem of inability to form a large current of light-emitting backlight, the number of carbon nanotubes emits less electrons, and the production area should not be too large, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to this embodiment.

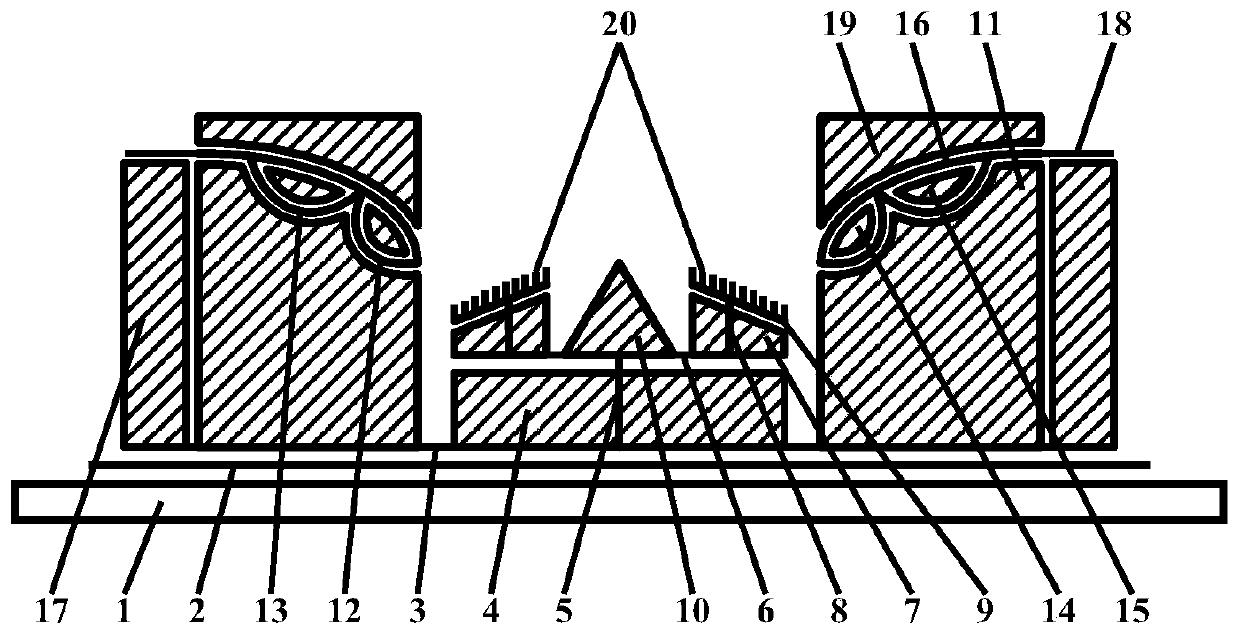

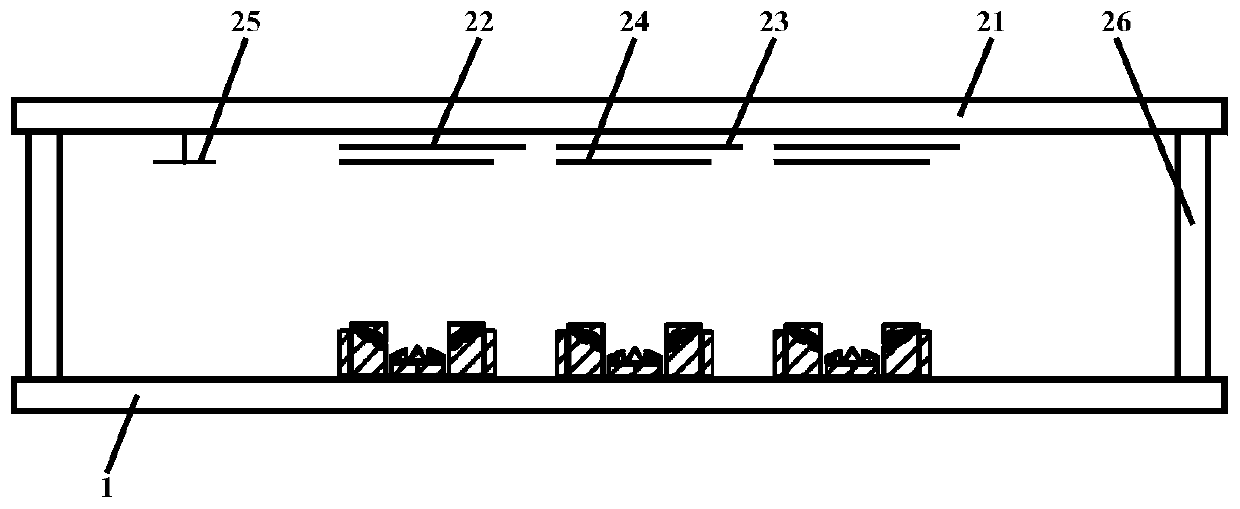

[0051] The light-emitting backlight of the single-ring circular convex surface cathode multi-swallow-wing arc gating structure of this embodiment is as follows: figure 1 , figure 2 and image 3 As shown, it includes a vacuum enclosure and a getter 25 accessory components located in the vacuum enclosure; the vacuum enclosure is composed of a front transparent hard glass plate 21, a rear transparent hard glass plate 1 and a glass narrow frame strip 26; the front transparent The hard glass plate has an anode high conductivity film layer 22, an anode silver thick line layer 23 and a thin luminous layer 24, the anode high conductivity film layer is connected to the anode silver thick line layer, and the thin luminescent layer is made on the anode high On the top of the conductive film layer; on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com