Heat energy recovery treatment device for coal desulfurization

A heat recovery and processing device technology, applied in the direction of heat exchangers, indirect heat exchangers, heat exchanger types, etc., can solve the problems of heat energy not being recycled, heat waste, etc., to achieve good results, easy to discharge and collect, and ensure The effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

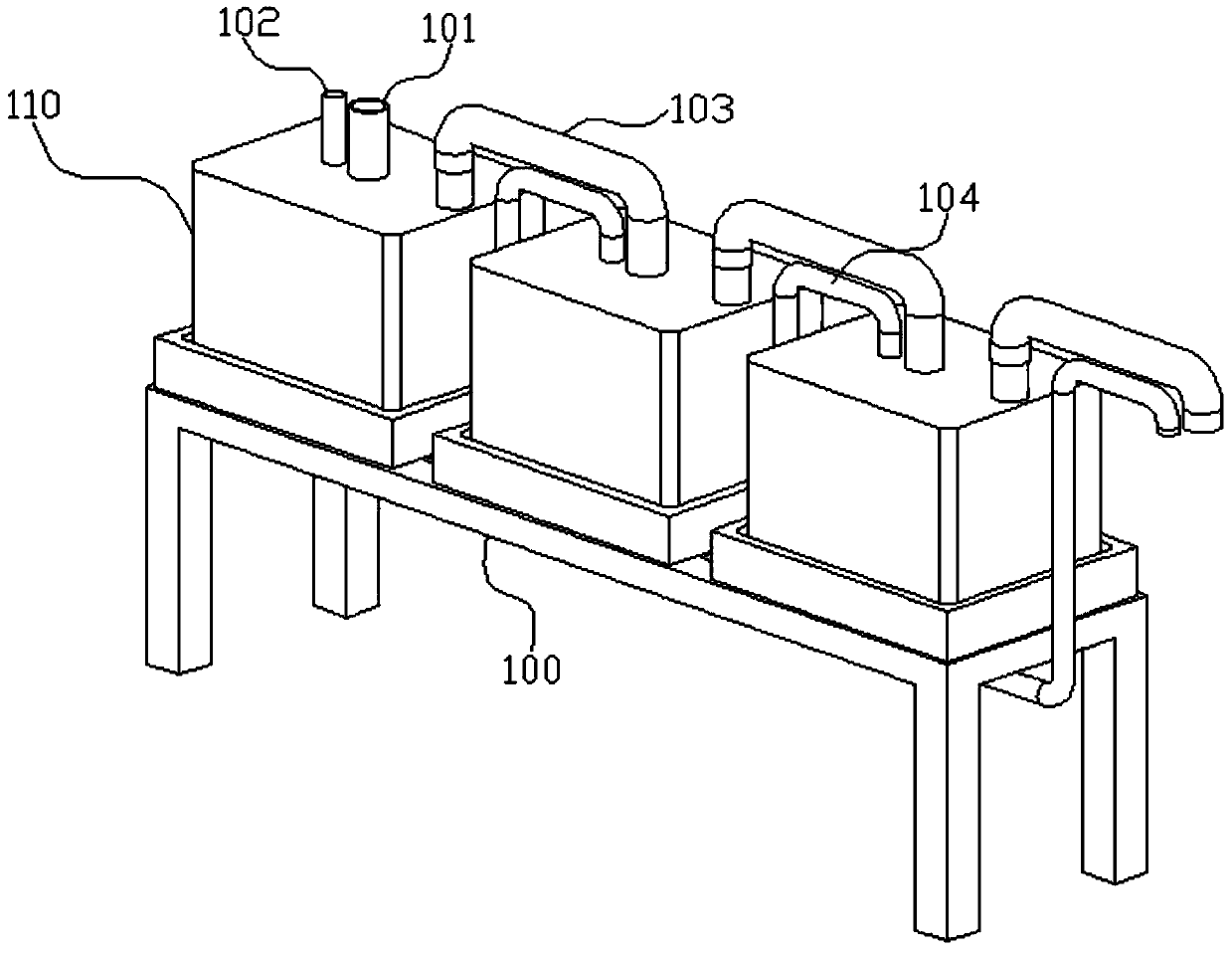

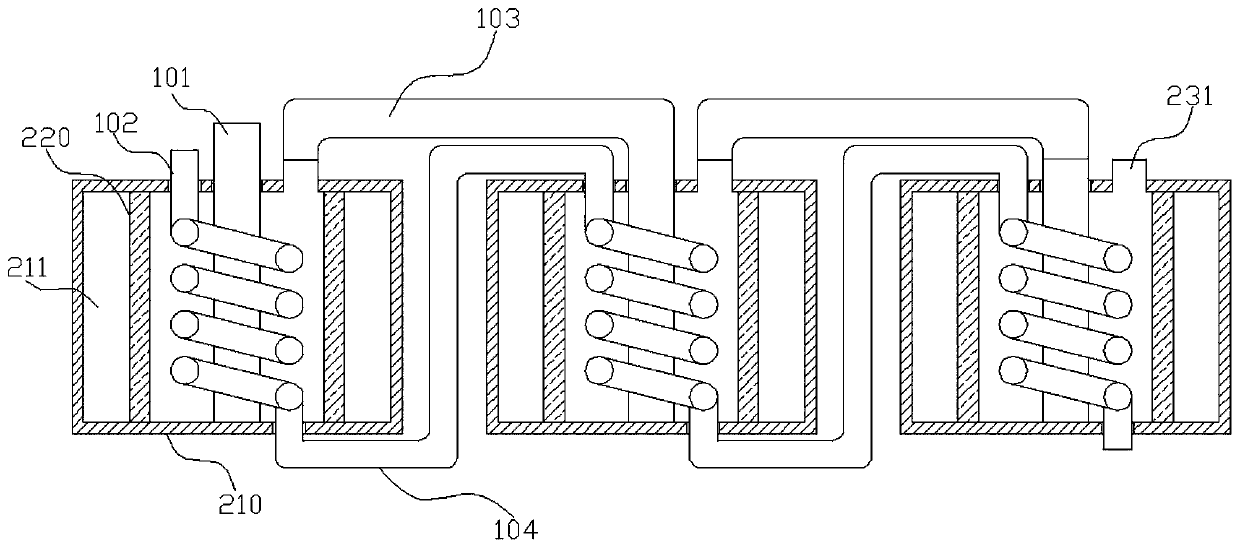

[0036] Such as Figure 1-2 As shown, the present embodiment provides a heat recovery treatment device for coal desulfurization, which includes a frame 100, on which a plurality of heat exchange mechanisms 110 with the same structure are provided, and the heat exchange mechanisms 110 include a shell 210, the shell 210 is provided with a heat exchange cavity 211, and the heat exchange cavity 211 is provided with a first air intake pipe 101 protruding above the shell 210, on the side wall of the first air intake pipe 101 and located below the heat exchange cavity 211 There is an air outlet at the first air inlet pipe 101, and a second air inlet pipe 102 in a spiral shape is sleeved on the outer surface of the first air inlet pipe 101 and located in the heat exchange chamber 211. side; heat exchange cavity 211 is provided with an attachment mechanism 220 set outside the second air intake pipe 102, above the heat exchange cavity 211 and between the attachment mechanisms 220 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com