Cationic polyacrylate fluoride-free waterproof agent and preparation method thereof

A technology of polyacrylate and fluorine-free water repellent, which is applied in the direction of textiles and papermaking, fiber treatment, and liquid-repellent fibers, etc., and can solve the problems affecting compactness, water resistance, scrub resistance, adhesion, human body and environmental hazards , waterproof level is not high, to achieve the effect of enhanced force, good stability, small particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

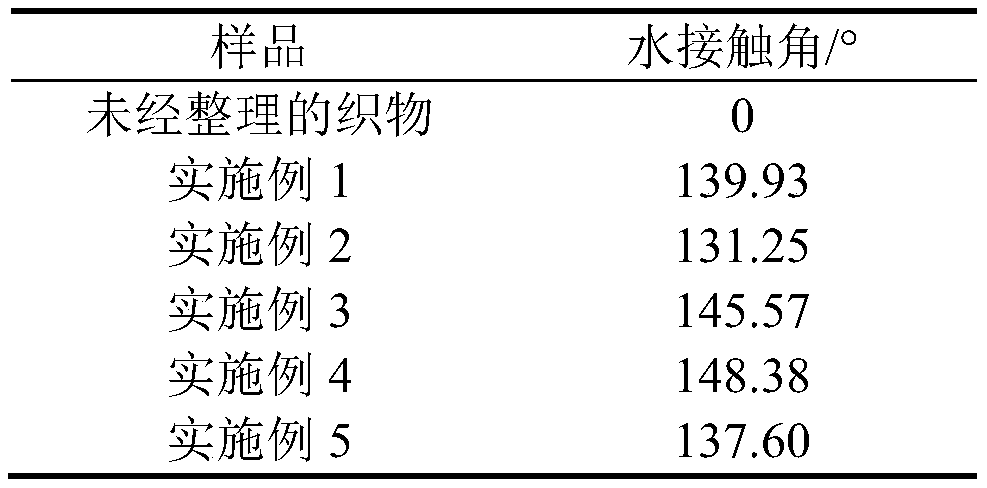

Examples

Embodiment 1

[0045] A kind of preparation method of cationic polyacrylate fluorine-free water repellent, specifically implement according to the following steps:

[0046]Step 1, prepare reactive cationic emulsifier

[0047] Step 1.1, add a certain amount of N,N-dimethylaminoethyl methacrylate, n-decane bromide, and acetone respectively to the flask equipped with a condenser tube to obtain a mixture, wherein N,N-dimethacrylate The molar ratio of methylaminoethyl ester to brominated n-decane is 1:1, and the mass ratio of acetone to N,N-dimethylaminoethyl methacrylate and brominated n-decane is 3:1. The mixture was left to react at 40°C for 24h;

[0048] Step 1.2, first distill the solvent from the mixture after the reaction in step 1, and then undergo recrystallization, where the recrystallization uses anhydrous ether to wash away unreacted monomers and solvents to obtain a reactive cationic emulsifier;

[0049] Step 2, prepare pre-emulsion

[0050] Step 2.1, mixing a certain amount of bu...

Embodiment 2

[0055] A kind of preparation method of cationic polyacrylate fluorine-free water repellent, specifically implement according to the following steps:

[0056] Step 1, prepare reactive cationic emulsifier

[0057] Step 1.1, add a certain amount of tert-butylaminoethyl methacrylate, bromododecane, and dioxane to the flask equipped with a condenser tube respectively to obtain a mixture, wherein tert-butylaminoethyl methacrylate The molar ratio of ester to dodecane bromide is 1:2, and the mass ratio of dioxane to the mixture of tert-butylaminoethyl methacrylate and dodecane bromide is 4:1. Stand at 45°C for 24 hours;

[0058] Step 1.2, first distill the solvent from the mixture after the reaction in step 1, and then undergo recrystallization, where the recrystallization uses anhydrous ether to wash away unreacted monomers and solvents to obtain a reactive cationic emulsifier;

[0059] Step 2, prepare pre-emulsion

[0060] Step 2.1, mixing a certain amount of butyl acrylate, meth...

Embodiment 3

[0065] A kind of preparation method of cationic polyacrylate fluorine-free water repellent, specifically implement according to the following steps:

[0066] Step 1, prepare reactive cationic emulsifier

[0067] Step 1.1, adding a certain amount of diethylaminoethyl methacrylate, tetradecane bromide, and acetonitrile respectively into a flask equipped with a condenser tube to obtain a mixture, wherein diethylaminoethyl methacrylate and decabromide The molar ratio of tetradecane is 1:3, and the mass ratio of acetonitrile, diethylaminoethyl methacrylate and tetradecane bromide is 5:1, and the mixture is allowed to stand at 50°C for 24 hours;

[0068] Step 1.2, first distill the solvent from the mixture after the reaction in step 1, and then undergo recrystallization, where the recrystallization uses anhydrous ether to wash away unreacted monomers and solvents to obtain a reactive cationic emulsifier;

[0069] Step 2, prepare pre-emulsion

[0070] Step 2.1, mixing a certain amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com