Low-slump loss concrete and preparation method thereof

A technology of slump loss and concrete, which is applied in the field of concrete, can solve the problems of concrete compression resistance, shrinkage, flexural resistance, wear resistance, reduction of concrete strength, and reduction of bond strength between cement and sandstone, etc., to achieve Improve anti-abrasion performance, reduce adsorption, and reduce impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: A kind of low slump loss concrete, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

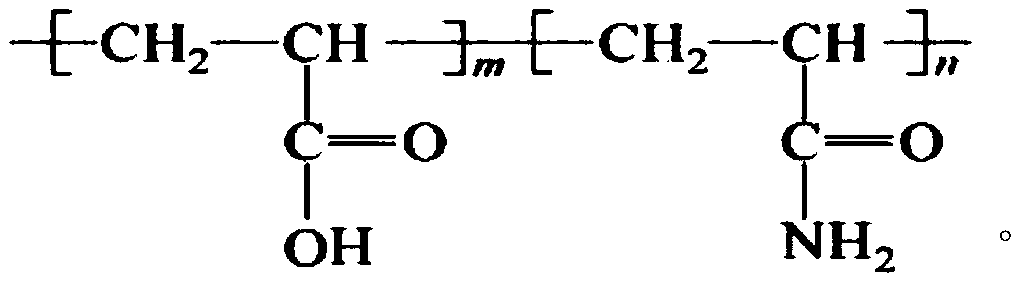

[0055] Step 1, preparation of admixture: put isopropanol and water into the reaction kettle, stir and mix evenly, raise the temperature to 85°C, add acrylic acid and sodium persulfate dropwise at the same time, complete the dropwise addition within 1.5h, keep warm for 2h, and drop to 25°C and adjust the pH to 9 with a 30% NaOH solution to obtain;

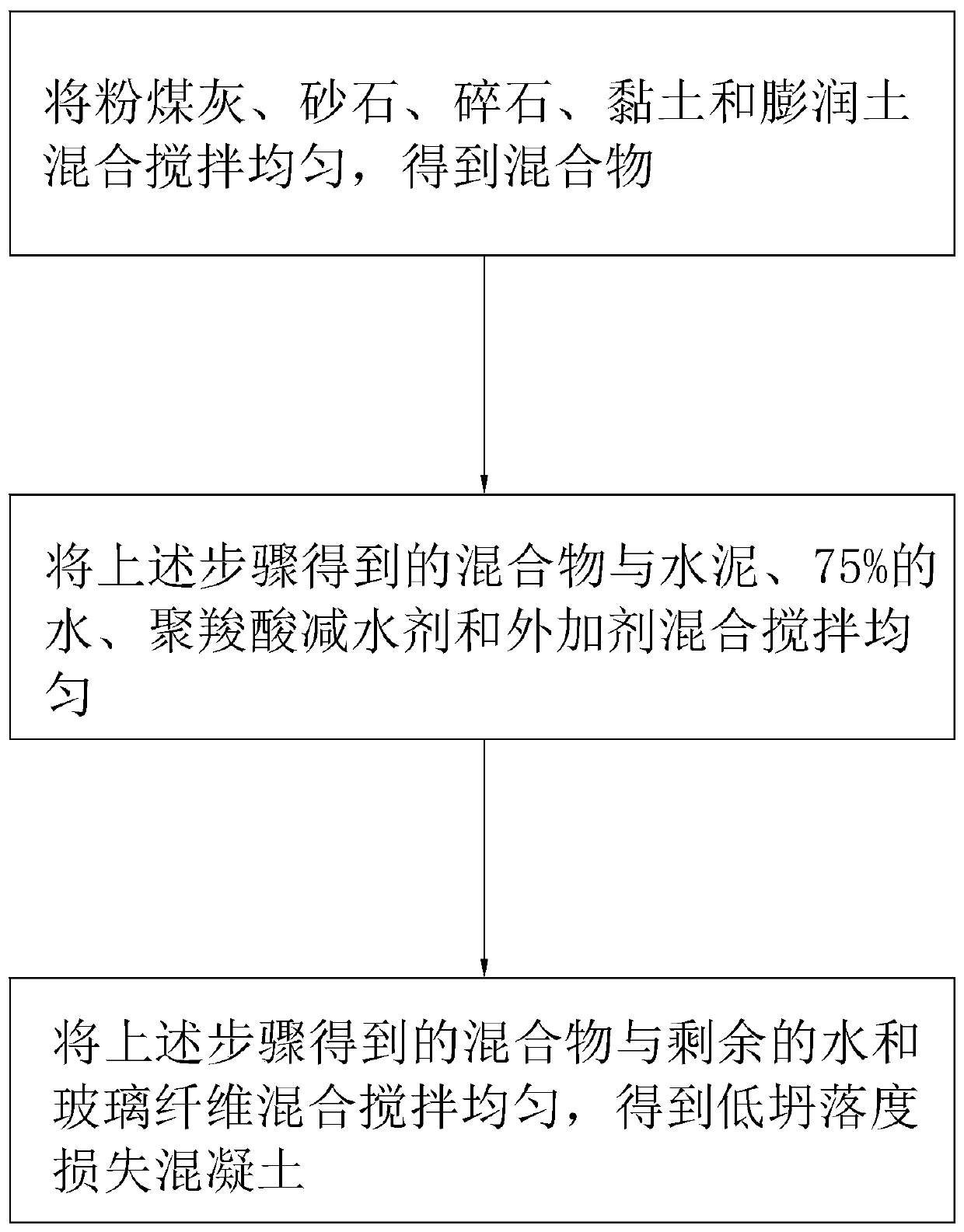

[0056] Step 2, mixing and stirring fly ash, sandstone, crushed stone, clay and bentonite evenly to obtain a mixture;

[0057] Step 3, mixing and stirring the mixture obtained in step 2 with cement, 75% water, polycarboxylate water reducer and admixture;

[0058] Step 4: Mix and stir the mixture obtained in Step 3 with the remaining water and glass fiber evenly to obtain low slump loss concrete.

[0059]In step one, the weight ratio of Virahol, water, i...

Embodiment 2-6

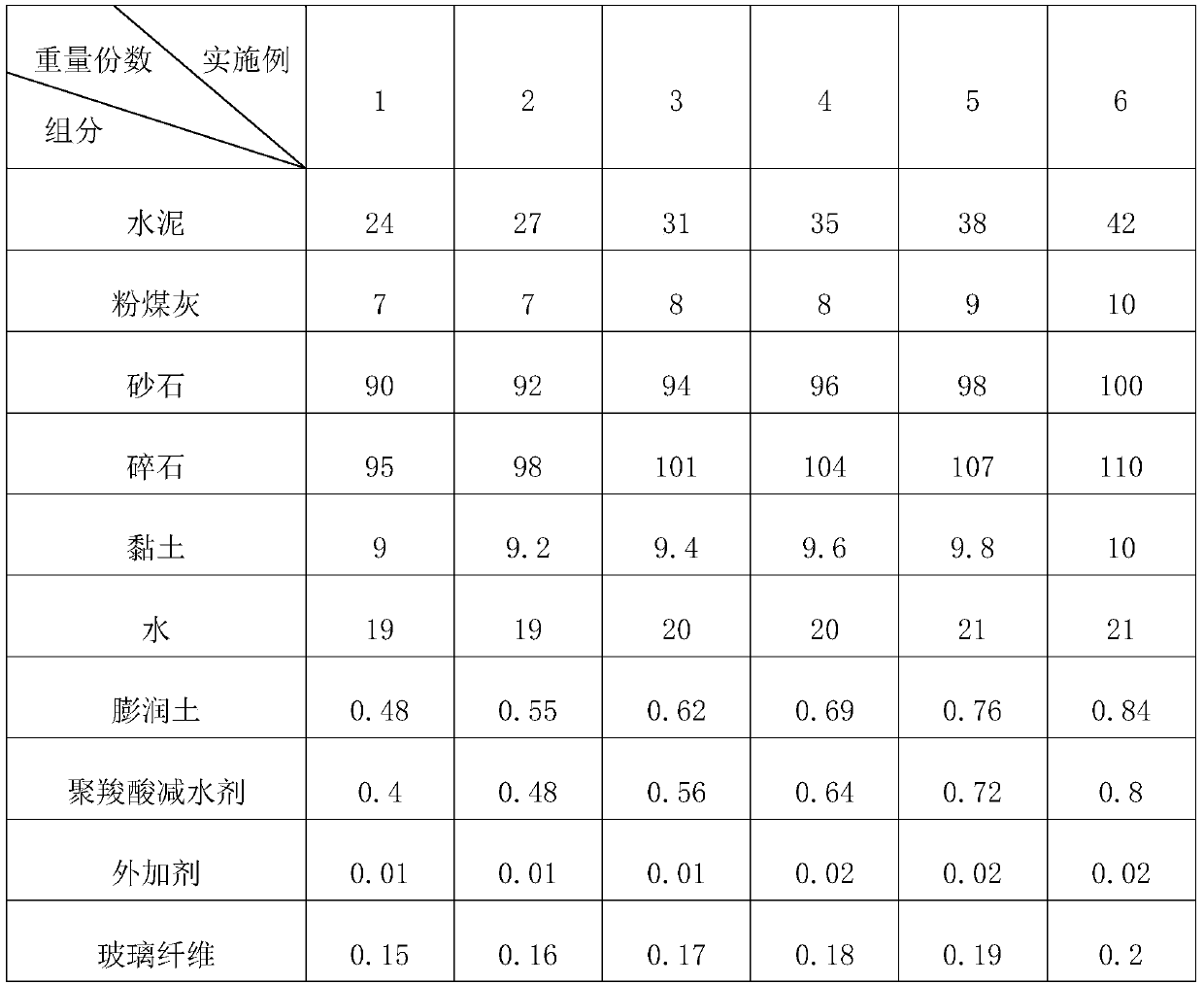

[0063] Example 2-6: a low slump loss concrete, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0064] Each component and parts by weight thereof in table 1 embodiment 1-6

[0065]

Embodiment 7

[0066] Example 7: A method for preparing low slump loss concrete, the difference from Example 1 is that in step 1, the admixture is prepared: put isopropanol and water into the reaction kettle, stir and mix evenly, and heat up To 90°C, add acrylic acid and sodium persulfate dropwise at the same time, the dropwise addition is completed within 2 hours, keep the temperature for 2 hours, lower to 25°C and adjust the pH to 11 with 30% NaOH solution to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com