A production equipment for graphite double-wrapping

A production equipment and double-wrapping technology, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of powder affecting performance and cleanliness defect rate, clogging, falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in further detail below in conjunction with the accompanying drawings.

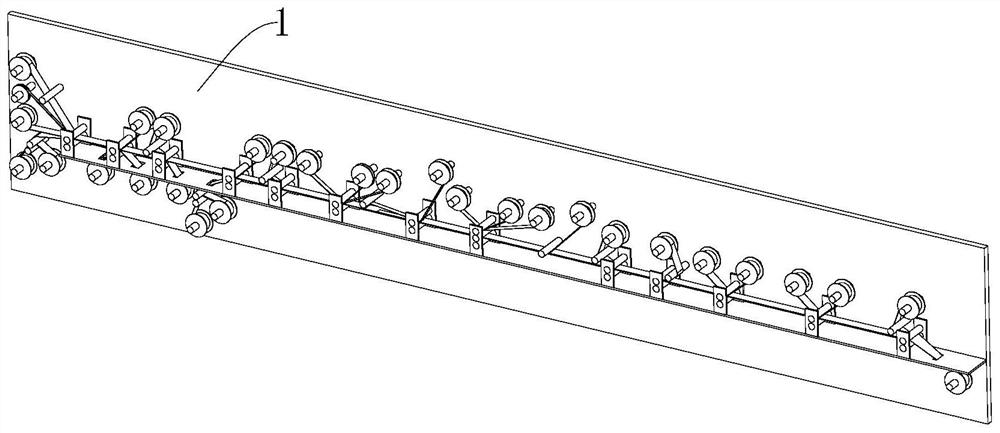

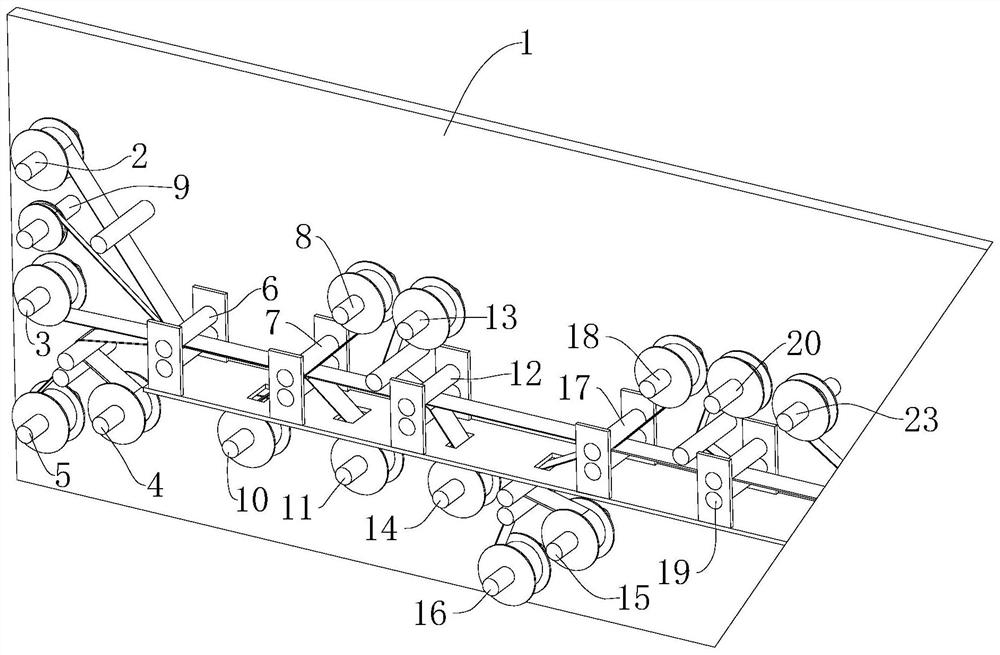

[0066] refer to figure 1 , is a kind of graphite double hemming production equipment disclosed by the present invention, including a layout wall 1, a driving device for driving the whole equipment is arranged in the layout wall 1, the driving device is selected as a motor, and the whole equipment is driven by a motor drive .

[0067] refer to figure 2 A graphite arrangement drum 2 is installed on the arrangement wall 1, and a graphite tray for winding graphite ribbons is sheathed on the graphite arrangement roller 2.

[0068] A first paper-lining drum 3 and a second paper-lining drum 4 are installed on the wall 1, the first paper-lining drum 3 is arranged on the upper side of the second paper-lining drum 4, the first paper-lining drum 3 and the second backing paper drum 4 are wound with a first backing paper tray and a second backing paper tray, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com