Machining method for metal guide wire

A processing method and metal wire technology, which is applied in the field of metal guide wire processing and manufacturing, can solve problems such as poor positioning and passing ability, winding and knotting of pipes, and prolonging operation time, so as to ensure flexibility and hardness, prevent corrosion or pollution, Avoid the effect of bending or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 of the present invention: This embodiment processes the metal guide wire used for meniscus repair surgery. The meniscus repair operation requires the use of a push rod or catheter. The push rod or catheter passes through the joint cavity with complicated conditions during the operation. The guide wire is a very important tool in meniscal repair surgery. The processing method of metal guide wire comprises the following steps:

[0025] a, according to the operation requirements, determine the effective length L and diameter D requirements of the metal guide wire, and select a metal wire with a length of 50 mm and a diameter of 1 mm. The metal wire in this embodiment is selected to be 316 stainless steel, 316 stainless steel It is medical stainless steel with strong corrosion resistance, suitable for processing and manufacturing medical equipment.

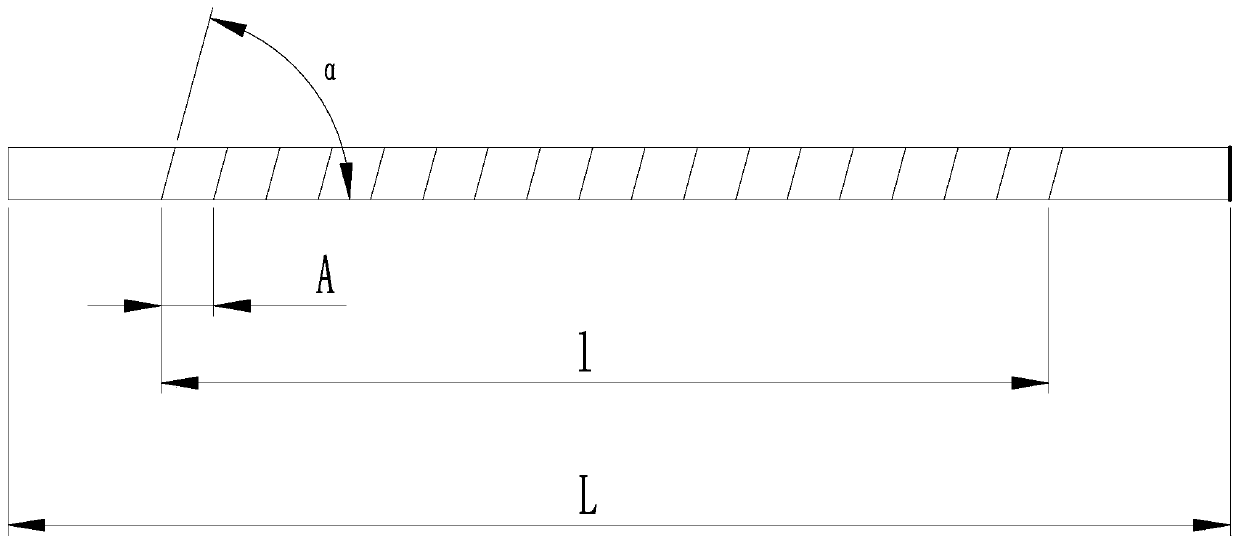

[0026] b. Use automatic straightening equipment to correct the stainless steel wire to prevent bending of the s...

Embodiment 2

[0031] Embodiment 2 of the present invention: the metal guide wire processed by the present invention is used for cardiac interventional therapy, a method for processing a metal guide wire, which is characterized in that it comprises the following steps:

[0032] a. According to the operation requirements, determine the effective length L and diameter D of the metal guide wire, and select a metal wire with a length of 150 mm and a diameter of 2 mm. Wire is a shape memory alloy with corrosion resistance and high elasticity, which is suitable for cardiac interventional surgery.

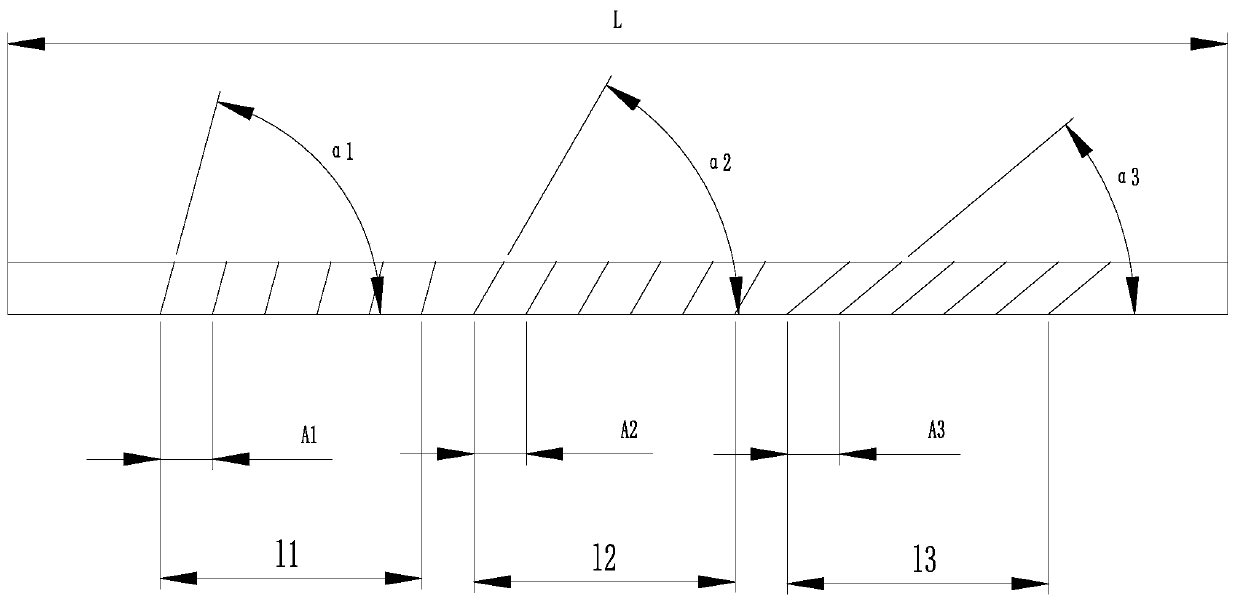

[0033] b. Use automatic straightening equipment to correct the nickel-titanium alloy wire to ensure the straightness of the nickel-titanium alloy wire and prevent kinks. Knuckles can prevent the metal guidewire from entering the heart vessel. Cardiac interventional therapy is an operation that requires very high precision. It has extremely high requirements on the performance of the metal guide wire. T...

Embodiment 3

[0039] Embodiment 3 of the present invention: this embodiment is used to process a metal guide wire for dredging small pipes, which have many bends and the inner diameter of the pipe is 12 mm. The processing method of metal guide wire comprises the following steps:

[0040] a. According to the requirements of use, determine the effective length L and diameter D of the metal guide wire, and choose a metal wire with a length of 800 mm and a diameter of 5 mm. The metal wire in this embodiment is made of stainless steel wire, which has excellent processing performance and corrosion resistance powerful.

[0041] b. Use automatic straightening equipment to correct the stainless steel wire to ensure that the stainless steel wire is straight and prevent kinks.

[0042] c. Grind both ends of the stainless steel wire into a shape that meets the requirements of use. It is difficult to dredge small pipes. One end of the stainless steel wire is polished into a sharp point, which is conven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com