Modified composite adsorbent as well as preparation method and application thereof

A composite adsorption and modification technology, used in chemical instruments and methods, adsorbed water/sewage treatment, alkali metal compounds, etc., can solve the problems of lack of adsorption groups, large specific surface area, easy to dissolve, etc., and achieve no secondary pollution. , high processing efficiency, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

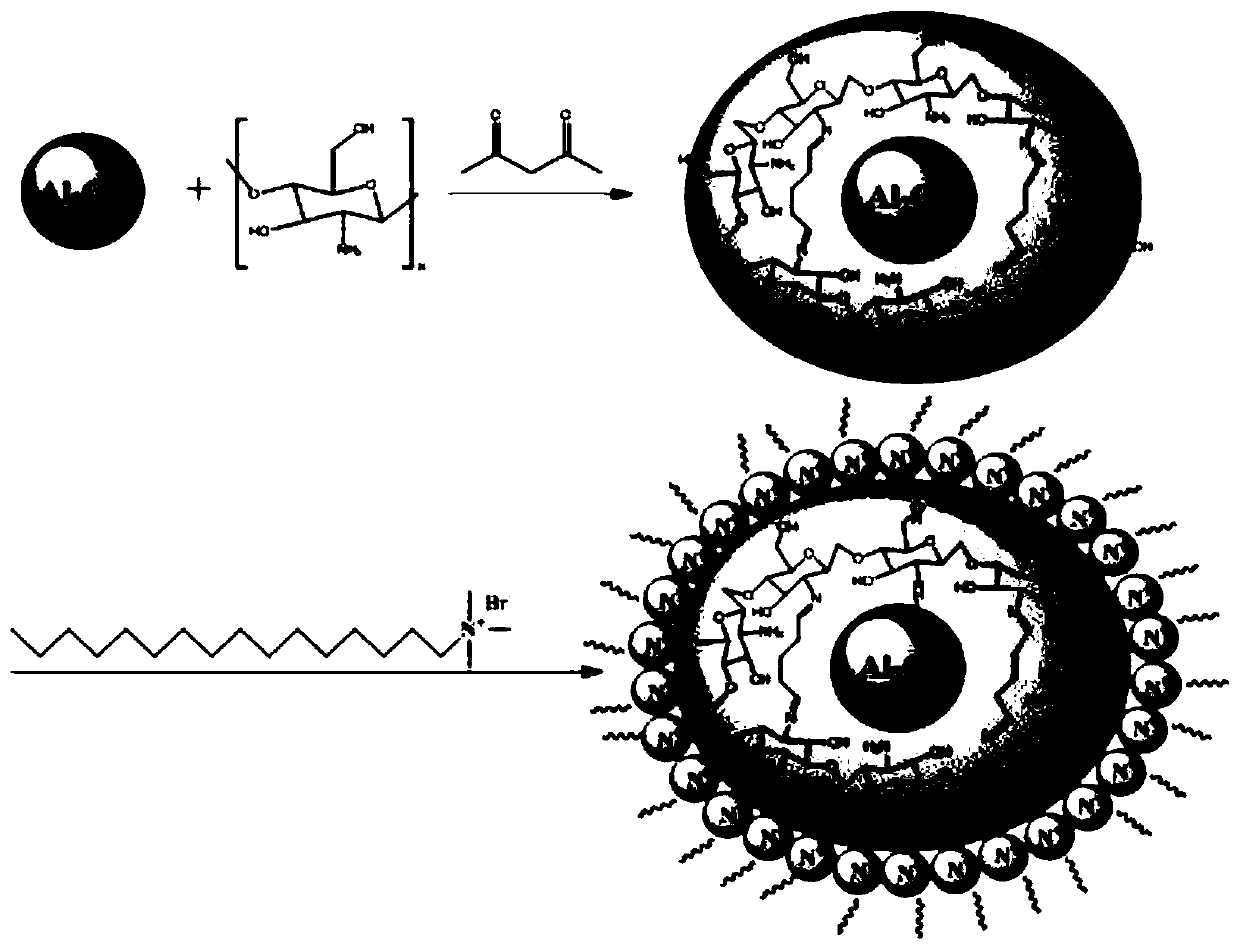

Method used

Image

Examples

Embodiment 1

[0033] 1. Add 6.18g of aluminum sulfate octadecahydrate to 30ml of deionized water. After fully dissolving, add 1mol / L sodium hydroxide solution under magnetic stirring to adjust the pH of the solution to 7, and ripen at 105°C for 18 Hours, after filtering, wash twice with 15ml ethanol, then wash with 15ml deionized water, dry in an oven at 60°C for 5 hours to obtain aluminum hydroxide solid, and heat aluminum hydroxide solid at 500°C for 3 hours in a muffle furnace to obtain alumina ;

[0034] 2. Dissolve 0.2g chitosan in 30ml acetic acid solution (1%), add 0.2g aluminum oxide again, under magnetic stirring, adjust solution temperature to 60 ℃, add 1.5ml glutaraldehyde (25%), generate The yellow colloid was then dried in an oven at 60°C for 14 hours, washed with 15ml of ethanol and deionized water after grinding, and then dried in an oven at 60°C for 1 hour to obtain a chitosan composite alumina adsorbent;

[0035] 3. Dissolve 0.06g of cetyltrimethylammonium bromide in 30ml ...

Embodiment 2

[0038]1. Add 8g of aluminum chloride to 60ml of deionized water. After fully dissolving, add 5mol / L sodium hydroxide solution under magnetic stirring to adjust the pH of the solution to 7.5. Mature at 60°C for 6 hours under sealed conditions, and filter After that, wash twice with 15ml of ethanol, then wash with 15ml of deionized water, dry in an oven at 80°C for 9 hours to obtain aluminum hydroxide solid, and heat the aluminum hydroxide solid at 500°C for 3 hours in a muffle furnace to obtain alumina;

[0039] 2. 0.5g chitosan is dissolved in 50ml acetic acid solution (5%), then add 0.2g aluminum oxide, under magnetic stirring, adjust solution temperature to 40 ℃, add 2.5ml glutaraldehyde (25%), generate The yellow colloid was then dried in an oven at 90°C for 18 hours, washed with 15ml of ethanol and deionized water after grinding, and then dried in an oven at 90°C for 3 hours to obtain a chitosan composite alumina adsorbent;

[0040] 3. Dissolve 0.1g of cetyltrimethylammoni...

Embodiment 3

[0042] 1. Add 3g of aluminum sulfate to 20ml of deionized water. After fully dissolving, add 0.2mol / L sodium hydroxide solution under magnetic stirring to adjust the pH of the solution to 6.5. Mature at 120°C for 24 hours under sealed conditions, and filter After that, wash twice with 2ml of ethanol, then wash with 2ml of deionized water, dry in an oven at 40°C for 18 hours to obtain aluminum hydroxide solid, and heat the aluminum hydroxide solid at 500°C for 3 hours in a muffle furnace to obtain alumina;

[0043] 2. 0.05g chitosan is dissolved in 20ml acetic acid solution (15%), then add 0.05g alumina, under magnetic stirring, adjust the solution temperature to 90 ℃, add 0.5ml glutaraldehyde (25%), generate The yellow colloid was then dried in an oven at 40°C for 15 hours, washed with 15ml of ethanol and deionized water after grinding, and then dried in an oven at 90°C for 1 hour to obtain a chitosan composite alumina adsorbent;

[0044] 3. Dissolve 0.01g of dimethylhexadecyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Equilibrium adsorption | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com