A kind of preparation method of hydroxyapatite/plga double-layer scaffold

A hydroxyapatite and double-layer technology is applied in the field of preparation of hydroxyapatite/PLGA double-layer scaffolds to achieve the effects of simple preparation process, suitable biodegradability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Preparation of α-TCP powder with uniform particle size

[0017] Calcium hydrogen phosphate and calcium carbonate are weighed at a molar ratio of 2:1, mixed in a pure water medium by wet ball milling, the ball milling speed is 400rpm, and the ball milling time is 2-4h. After ball milling, place them in an oven at 80°C to dry overnight. After drying, the powder is calcined in a muffle furnace at 1250-1400°C for 2-4 hours, then taken out, and rapidly cooled in a blast environment. Then use zirconia ball milling, use ethanol as the ball milling medium, wet ball milling at 450 rpm for 4 hours, and dry in an oven at 80°C to obtain α-TCP (α-tricalcium phosphate) powder with uniform particle size.

Embodiment 2

[0019] Preparation concentration is the gelatin solution (50-100g / L) of 5-10% (w (g) / v (ml)), the above-mentioned gelatin solution and glycerin, mass percent concentration are 1wt% glutaraldehyde solution by volume ratio 100 : 10:1 for mixing, and at the same time, the above-mentioned α-TCP powder of Example 1 was added to the mixed solution at a solid-to-liquid ratio of 0.6-1g / mL to the gelatin solution to obtain a self-curing calcium phosphate bone cement 3D printing "ink". The mixed solution of gelatin, glycerin and glutaraldehyde in the above ratio is used as the solidification solution of α-TCP, so that the bone cement blending slurry has suitable injectability and viscosity. The "ink" has good injectability and can pass 0.3- The 0.5mm printing needle is used for printing, and its viscosity meets the requirements of vertical accumulation at room temperature, which can be applied to vertical deposition 3D printing technology.

Embodiment 3

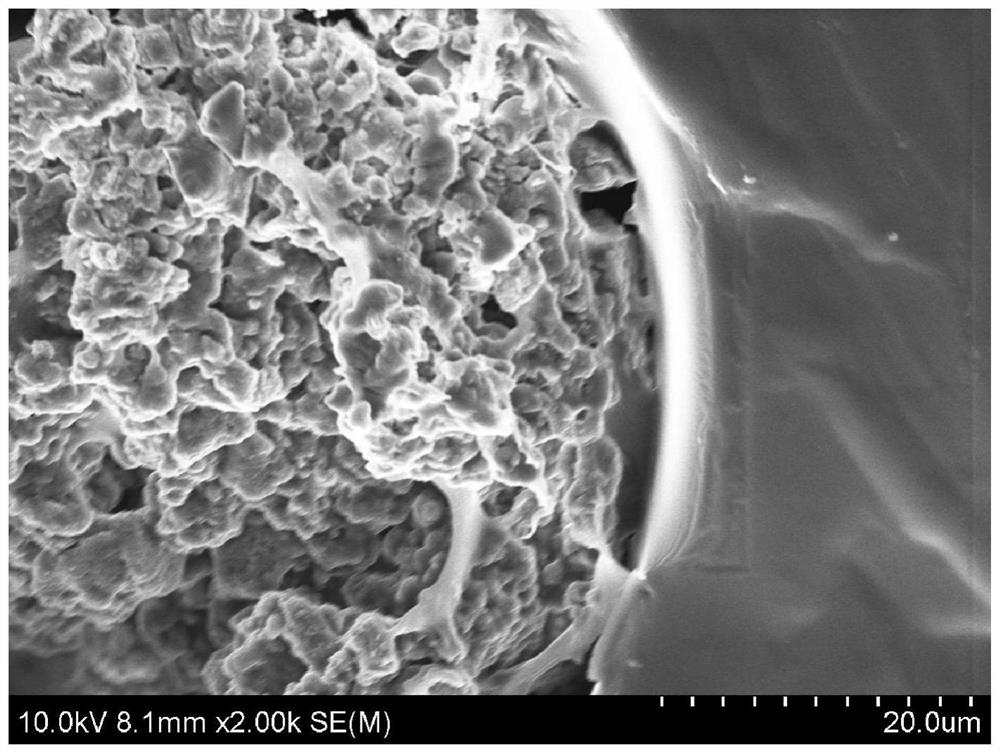

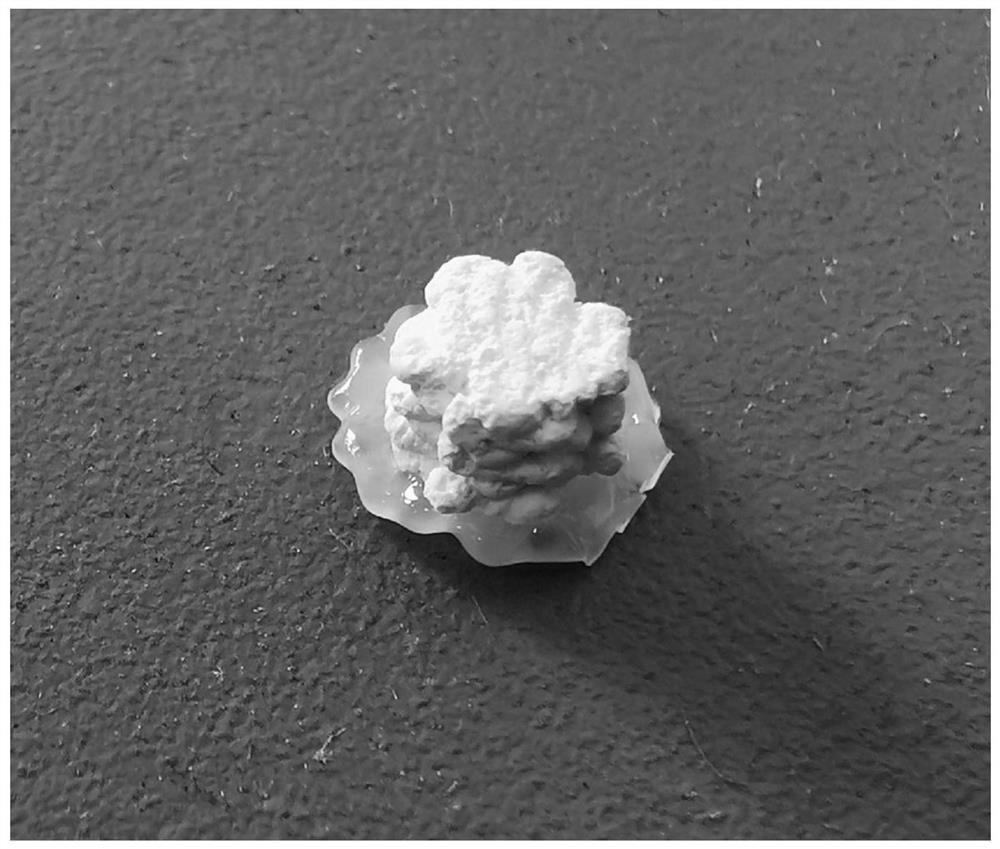

[0020] Embodiment 3 Preparation of hydroxyapatite / PLGA double-layer scaffold

[0021] Put the self-curing calcium phosphate bone cement 3D printing "ink" in the above example 2 into the low-temperature printing nozzle, and the discharge needle is selected as 0.3-0.5mm; put the PLGA particles into the high-temperature printing nozzle, and the molecular weight of the PLGA particles is 100,000-40 10,000, LA / GA is 75 / 25-90 / 10, both ends of the PLGA molecular chain can be terminated by ester groups, hydroxyl groups or carboxyl groups, the discharge needle is 0.17-0.4mm, and the printing temperature is 180-200°C. Using the dual-nozzle printing mode of the 3D printer, the two materials were printed sequentially according to the model design to obtain a hydroxyapatite / PLGA double-layer scaffold.

[0022] A PLGA base with a diameter of 6 mm and a double-layer scaffold of hydroxyapatite with a diameter of 4 mm were printed and prepared by the above method. After printing, the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com