Antioxidant for rubber, and preparation method and application thereof

An anti-oxidant and rubber technology, applied in the field of rubber, can solve the problems of poor anti-oxidation performance, achieve the effect of enhancing anti-oxidation performance, color and Mooney viscosity, etc., and enhancing the anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

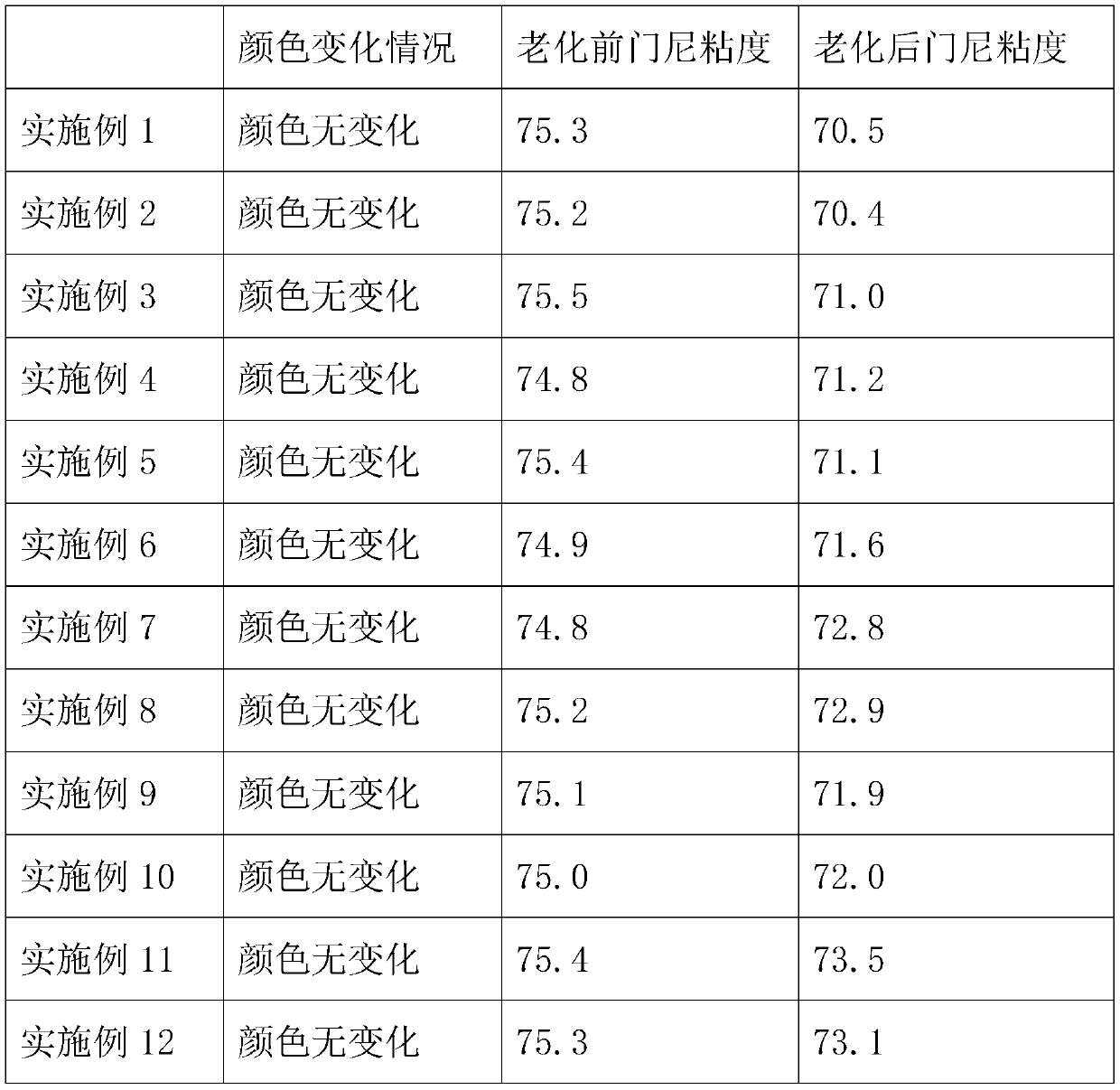

Examples

Embodiment 1

[0064] An antioxidant for rubber, comprising the following components:

[0065] EPDM rubber 30kg; white carbon black 35kg; stearic acid 1kg; polyisobutylene 36kg; phosphite powder 1.25kg; dobutamine hydrochloride 0.75kg.

[0066] The preparation method of antioxidant for rubber is as follows:

[0067] S1, mixed raw materials, specifically as follows:

[0068] First add EPDM rubber into the granulator and crush it into particles with a particle size of 1 mm, then add 30 kg of EPDM rubber crushed into particles, 35 kg of white carbon black, 1 kg of stearic acid, and polyisobutylene into the internal mixer. 36kg, phosphite powder 1.25kg, dobutamine hydrochloride 0.75kg.

[0069] S2, internal refining, the details are as follows:

[0070] Stir and mix the raw materials in the internal mixer under pressure, and control the temperature of the internal mixer to 60°C, the mixing time is 10 minutes, and every 3 minutes during the stirring process, lift the weight of the mixed raw ma...

Embodiment 2

[0074] The difference with embodiment 1 is:

[0075] S2, internal refining, the details are as follows:

[0076] Stir and mix the raw materials in the internal mixer under pressure, and control the temperature of the internal mixer to 65°C, the mixing time is 8 minutes, and every 2 minutes during the stirring process, lift the weight of the mixed raw materials in the reaction vessel, and stir Invert the mixed stock in the reaction vessel.

Embodiment 3

[0078] The difference with embodiment 1 is:

[0079] S2, internal refining, the details are as follows:

[0080] Stir and mix the raw materials in the internal mixer under pressure, and control the temperature of the internal mixer to 61°C, the mixing time is 9 minutes, and every 3 minutes during the stirring process, lift the weight of the mixed raw materials in the reaction vessel, and stir Invert the mixed stock in the reaction vessel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com