Door plate gluing device

A door panel and gluing technology, which is applied in the field of gluing machines, can solve the problems of uneven, time-consuming and laborious gluing, etc., and achieve the effect of speeding up the production rhythm, reducing the number of gluing times, and replenishing in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

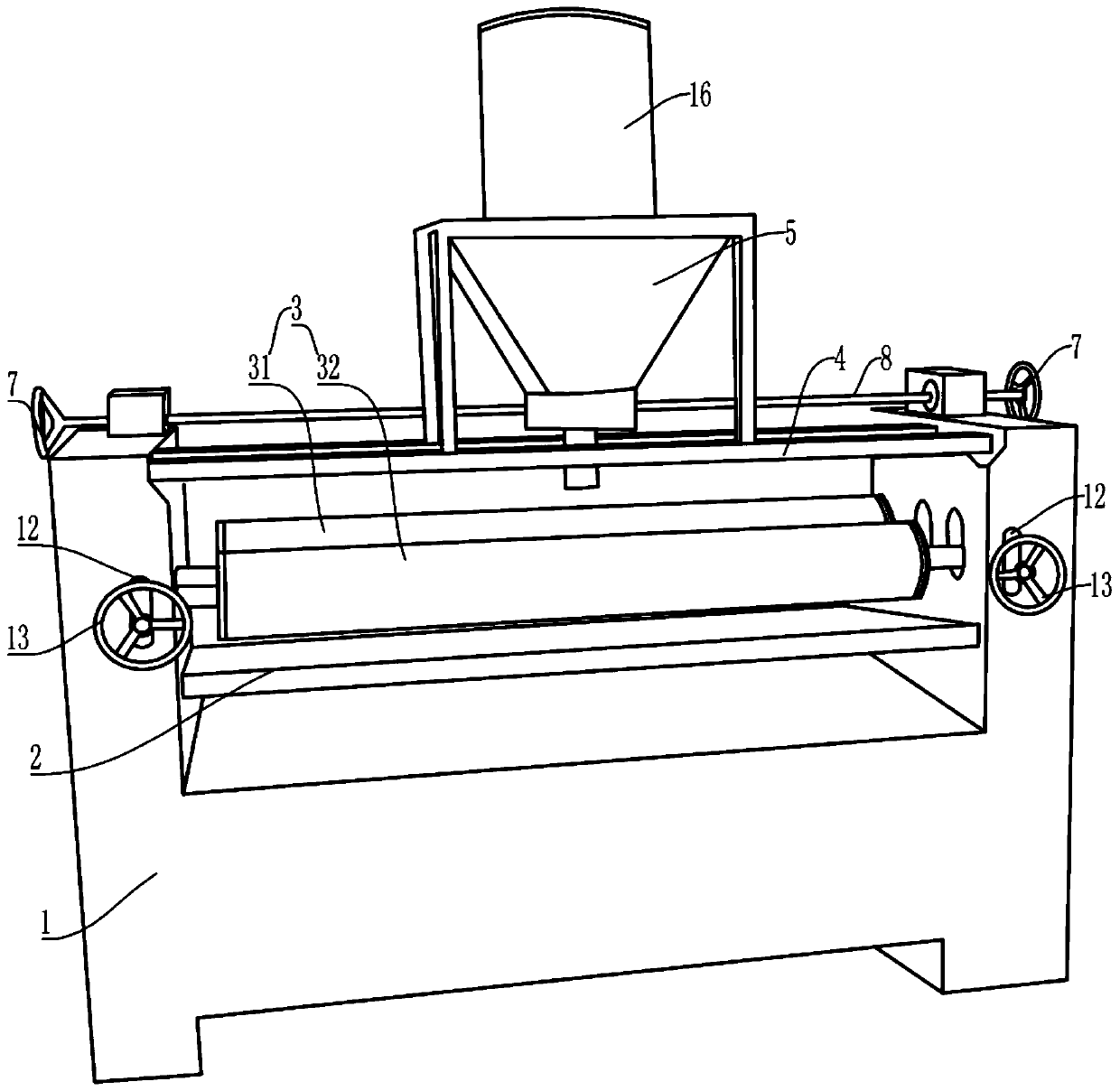

[0041] Embodiment one is basically as attached Figure 1 to Figure 4 Shown:

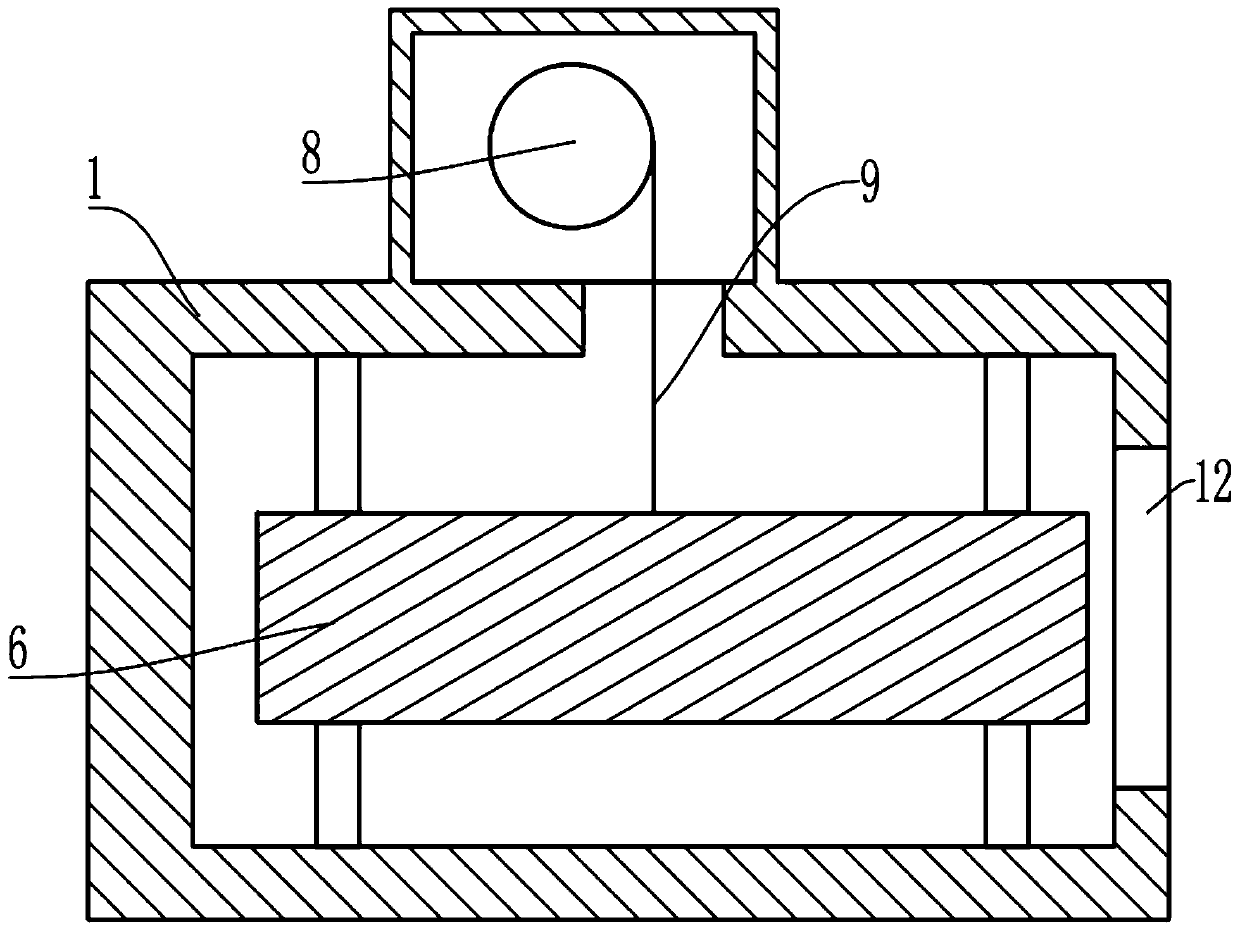

[0042] The door panel gluing device includes a frame 1, which is provided with a U-shaped through groove, and the frame 1 is installed with a platform plate 2 through screws (the platform plate 2 is located in the U-shaped channel of the frame 1) , the top of the bearing plate 2 is provided with a pair of glue rollers 3, and the bearing plate 2 is used to place plates; the top of the frame 1 is fixedly connected with a support plate 4 by bolts, and the support plate 4 is fixedly connected with a glue bucket 5 by screws (the glue hopper 5 is funnel-shaped, and the bottom of the glue barrel 16 is integrally formed with an opening), the glue pair roller 3 includes a roller one 31 and a roller two 32, and both the roller one 31 and the roller two 32 are nitrile rubber rollers.

[0043] A height adjustment unit and a width adjustment unit are installed on the left and right sides of the gluing pair rolle...

Embodiment 2

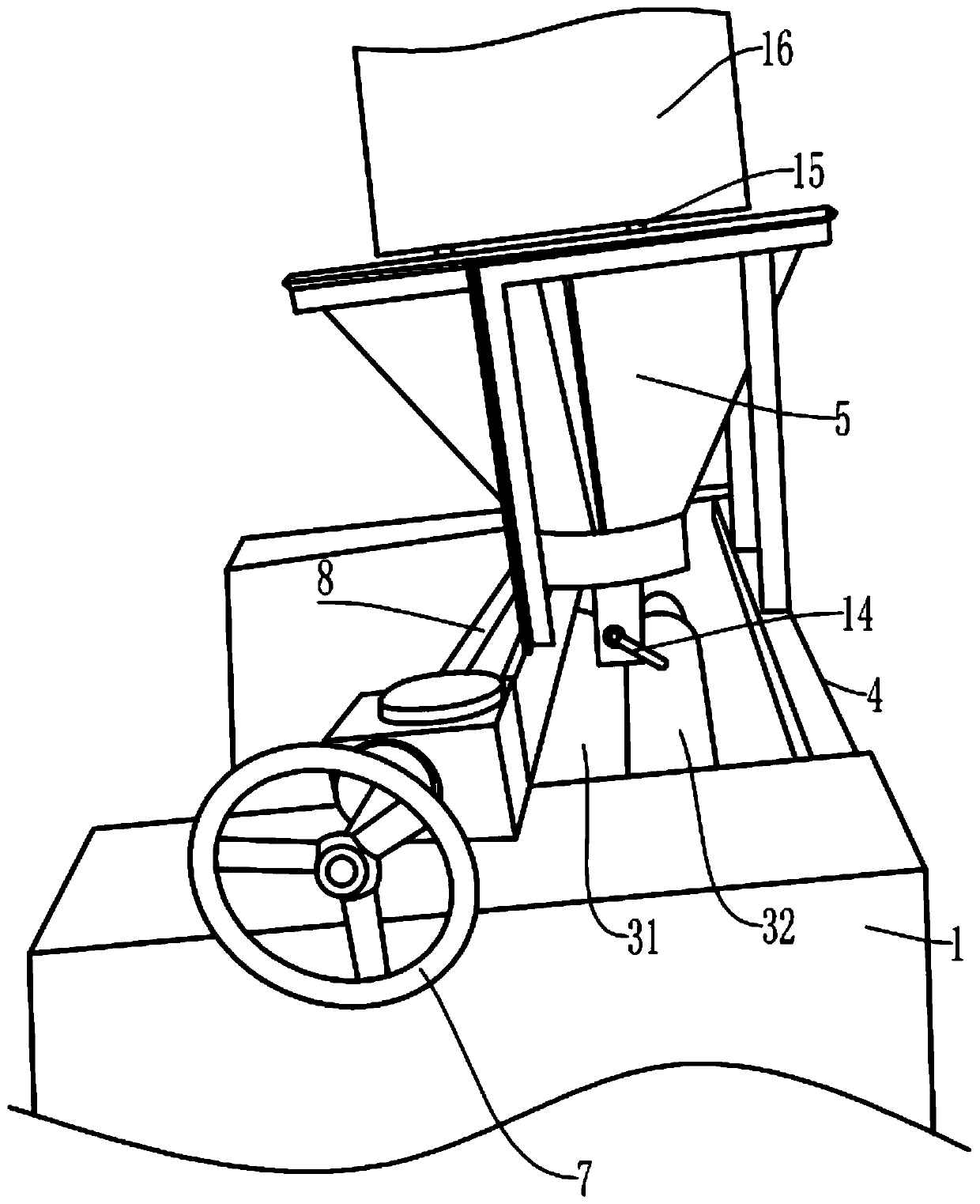

[0056] Embodiment two is basically as attached Figure 5 to Figure 8 As shown, embodiment two has carried out following improvement on the basis of embodiment one:

[0057] Also includes conveyor belt 17, lifting unit and pushing unit; Figure 7 , the conveyor belt 17 is set on the support plate 15 (the support plate 15 stretches out from the upper rubber bucket 5, and the support plate 15 is much elongated relative to the first embodiment), the rubber bucket 16 is placed on the conveyor belt 17, and the support plate 15 plays a role in the conveyor belt 17 at this time. supporting role.

[0058] combine Figure 6 , the lifting unit comprises a conveyor belt 18 and a lifting plate 19 of a chain drive, the conveyor belt 18 is fixedly connected with a connecting plate, and the lifting plate 19 is installed on the connecting plate by screws (this structure is the same as that of the chain drive in the prior art to drive the forklift to load goods). The mode that the fork moves...

Embodiment 3

[0067] combine Figure 9 , Embodiment 3 On the basis of Embodiment 2, an auxiliary lifting unit 27 is added on the right side of the conveyor belt 17. The auxiliary lifting unit 27 is different from the lifting unit on the right side in that the auxiliary lifting unit 27 does not have a lifting unit on the right side The baffle plate 26 and the ball 25 in the lifting unit are used to drop the rubber bucket 16 replaced from the conveyor belt 17 to a height that is convenient for manual removal, so as to facilitate the recovery of the replaced empty rubber bucket 16 by workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com