A cross-scale three-dimensional laser direct writing processing device

A three-dimensional laser and processing device technology, used in additive processing, metal processing equipment, laser welding equipment, etc., can solve problems such as poor mechanical strength, damage to target structures, and low degree of structural polymerization, so as to improve processing efficiency and ensure processing. Accuracy, the effect of extending the range of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

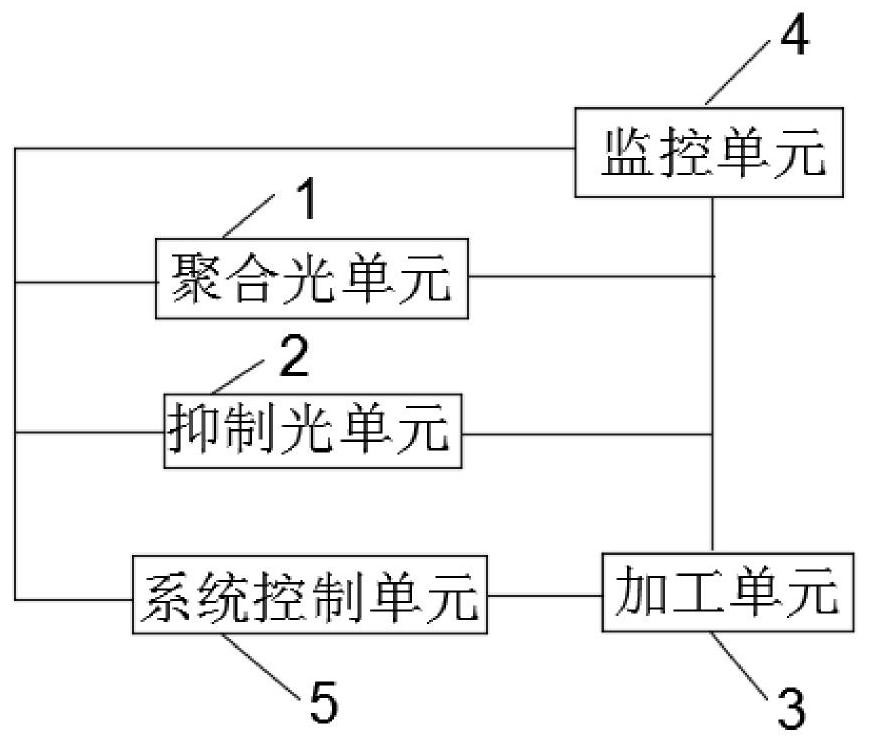

[0024] Such as figure 1 , the converging light unit 1, suppressing light unit 2, processing unit 3, and monitoring unit 4 of the three-dimensional laser direct writing processing device are all connected to the system control unit 5, and the converging light of the converging light unit 1 and the suppressing light of the suppressing light unit 2 enter the processing Unit 3.

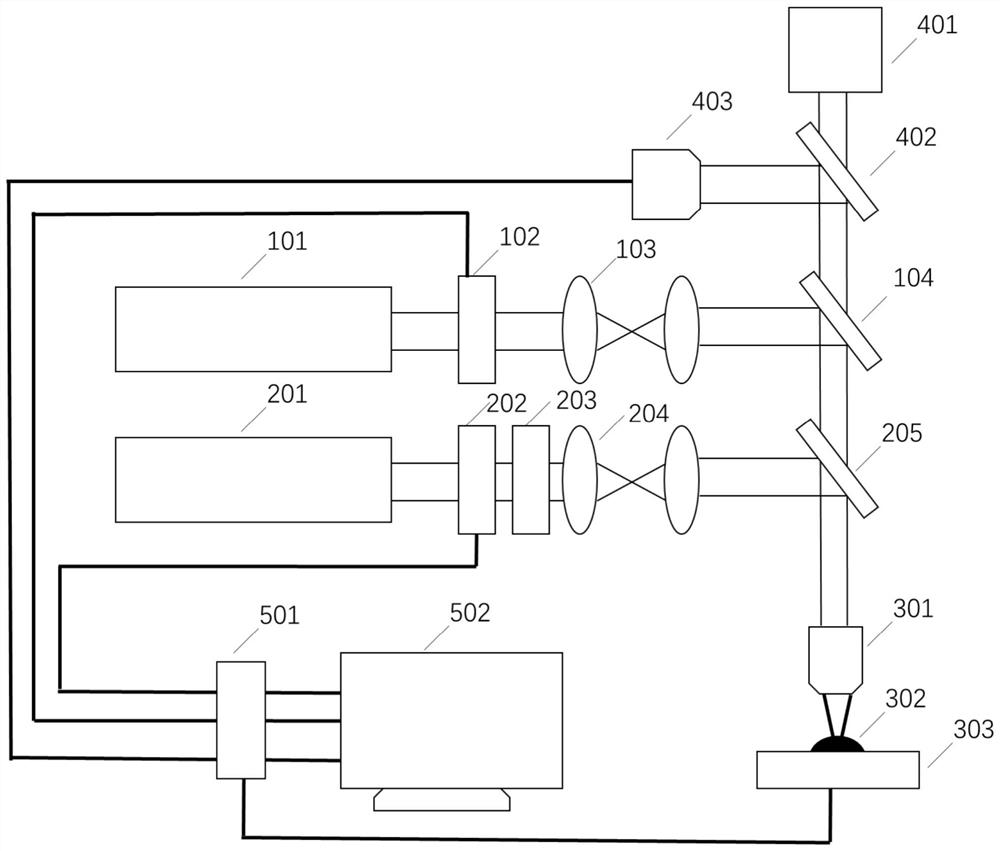

[0025] Such as figure 2 , on the optical platform, place the polymerization laser 101, the light intensity modulator one 102, the lens combination one 103 and the half mirror two 104 in sequence along the straight line direction, and the incident light direction of the half mirror two 104 is related to the device The placement directions are consistent, and the outgoing light is coupled into the focusing objective lens 301 . Suppression laser 201, light intensity modulator 2 202, beam profile controller 203, lens combination 2 204, half mirror 3 205 are placed on the optical platform in sequence along ...

Embodiment 2

[0028] The differences between this example and Example 1 are as follows, and the rest are the same: the initiator and inhibitor are photoluminescent materials such as isopropylthioxanthone, and the wavelength of the polymerization absorption peak is 380 nm. The absorption peak wavelength is suppressed at 440 nm. The wavelength of the illumination source is 605 nm. The output light wavelength of the laser 101 for polymerization is 800 nm. The output light wavelength of the suppressing laser 201 is 532 nm. Light intensity modulator 1 102 is a commercial acousto-optic modulator, light intensity modulator 2 202 is a commercial acousto-optic modulator, and beam profile controller 203 is a digital micromirror device. The focusing lens 301 is a water immersion objective lens.

Embodiment 3

[0030] The differences between this example and Example 1 are as follows, and the rest are the same: the initiator is 2,5-bis(p-dimethylaminooctivalerolactone)-cyclopentanone, and the absorption peak wavelength is 511 nm. The inhibitor is the photoinactivation material tetraethylthiuram disulfide, and the absorption peak wavelength is 375 nm. The wavelength of the illumination source is 535 nm. The output light wavelength of the laser 101 for polymerization is 800 nm. The output light wavelength of the suppressing laser 201 is 375 nm. The light intensity modulator 1 102 is a combined device of a half-wave plate and a Glan galvanometer, the light intensity modulator 2 202 is a combined device of a half-wave plate and a Glan galvanometer, and the beam profile controller 203 is a spatial light modulation. The focusing lens 301 is a dry objective lens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com