A cam lathe numerical control system

A numerical control system and cam technology, applied in the general control system, control/regulation system, digital control, etc., can solve the problems of time-consuming and labor-intensive change, small equipment investment, poor processing accuracy, etc., to improve the economic benefits of enterprises and equipment investment Small, the effect of reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: The present invention provides a numerical control system for a cam lathe, including a cam lathe and a numerical control system.

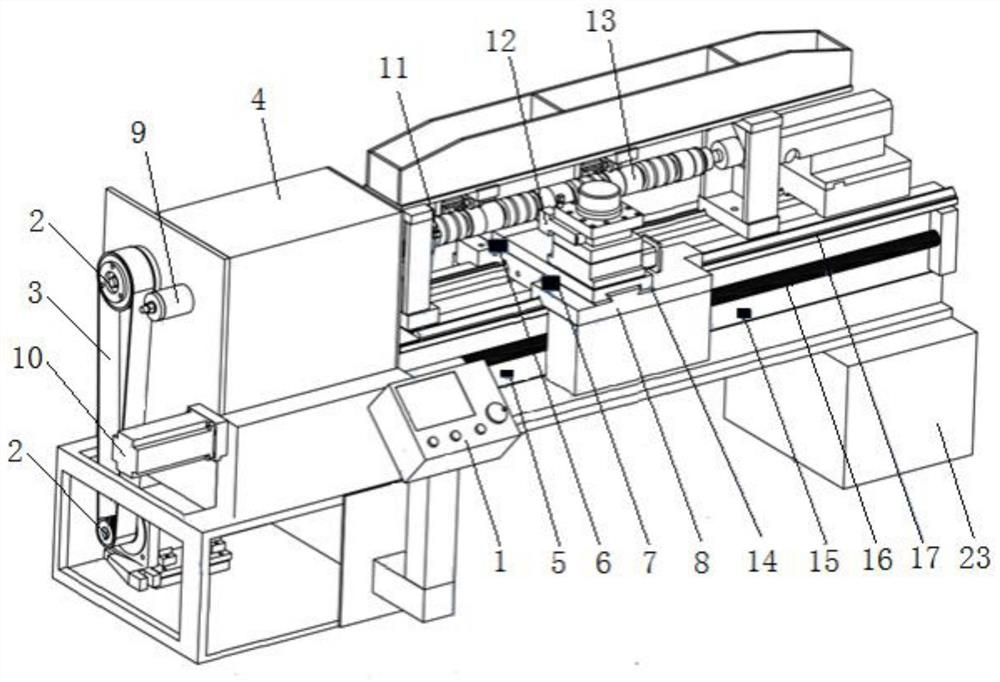

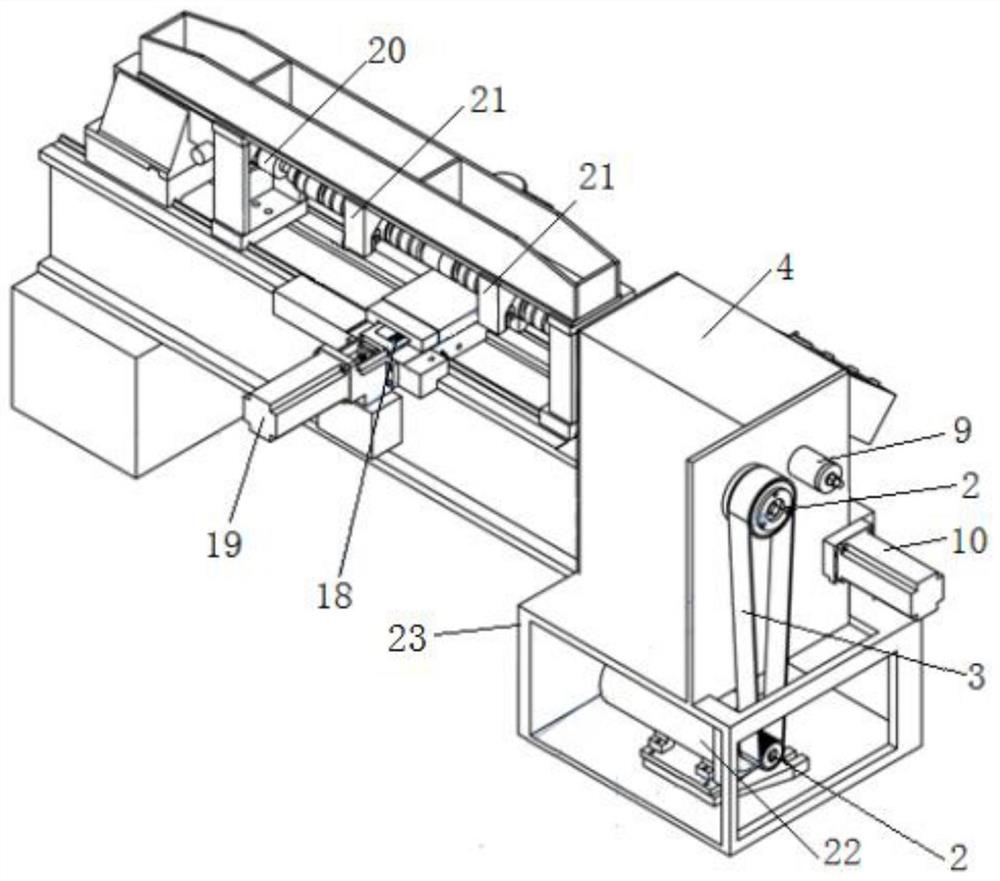

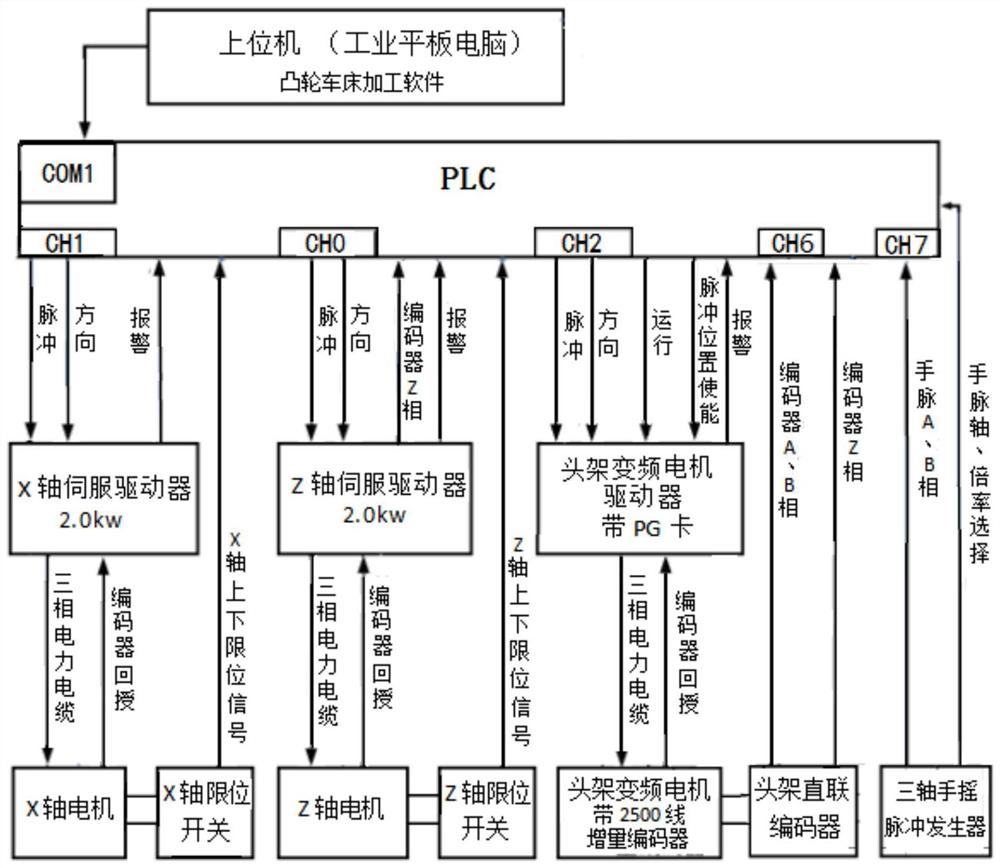

[0032] The structure of the cam lathe is as figure 1 ,2 shown. The cam lathe is provided with a frame 23, a gear box 4, an operating table 1, a headstock direct-coupled encoder 9, an X-axis servo motor 19, a Z-axis servo motor 10, a turning tool 12 and a headstock variable frequency motor 22; One side is provided with a gear box 4, and the outer side of the gear box is equipped with a synchronous wheel 2, a synchronous belt 3, a head frame direct-connected encoder 9 and a Z-axis servo motor 10, and a head frame variable frequency motor 22 is installed under the gear box, and the head frame variable frequency motor The head frame 11 is connected through the transmission mechanism in the synchronous wheel 2, the synchronous belt 3, and the gear box. The console 1 is installed in front of the gear box; Transmission screw 18, the...

Embodiment 2

[0057] Embodiment 2: use the cam lathe numerical control system processing cam of embodiment 1 of the present invention, the specific operation process is:

[0058] 1. First complete the writing of data.xlsx and processing.xlsx files:

[0059]In the present invention, the numerical control system of the cam lathe will use two files for each cam product, one for data.xlsx, and the other for processing.xlsx; Figure 6 and Figure 7 surface.

[0060] ⑴. According to the cam to be processed, the type of the cam to be processed is distinguished, and the parameters related to the workpiece are extracted from the product diagram;

[0061] ⑵. Open the data.xlsx electronic form in the host computer ( Figure 6 table) file:

[0062] a: Convert the lift data of the three types of cams in the product diagram into electronic cam data and fill them in respectively Figure 6 In the table, in columns A to C, rows 1 to 360, fill in column A for the exhaust cam, column B for the intake cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com