Photovoltaic collector processing technology

A processing technology and heat collector technology, applied in the field of photovoltaic heat collector processing technology, can solve the problems of sticky separation, insufficient sticky strength, etc., and achieve the effects of improving stability, improving efficiency, and connecting stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

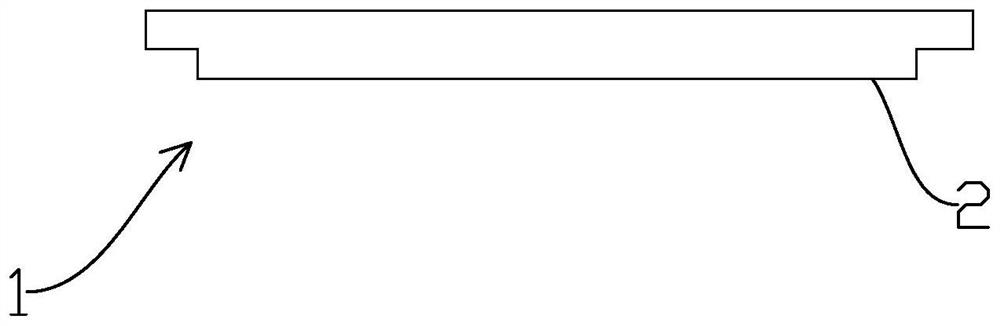

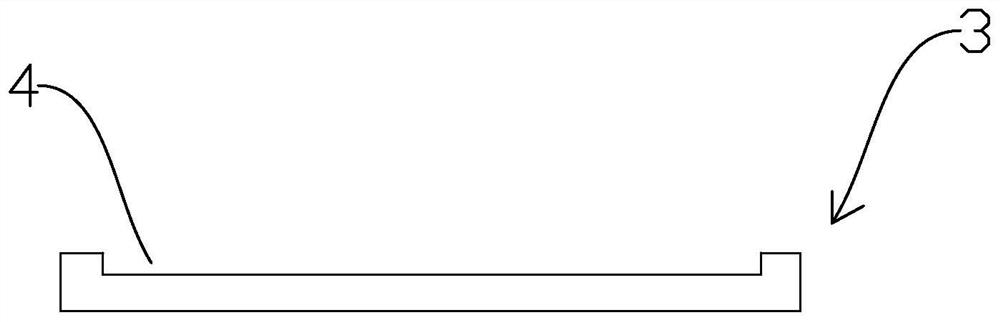

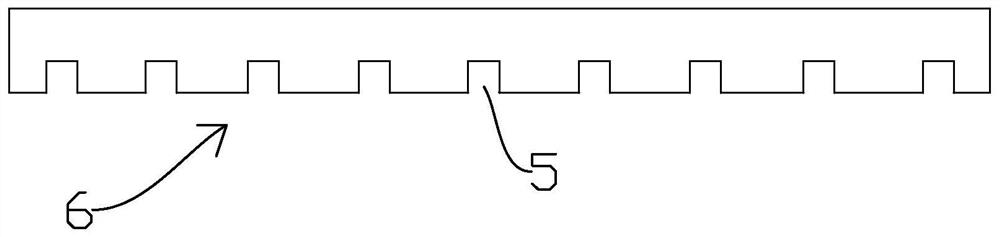

[0033] Such as Figure 1-5 Shown, the photovoltaic heat collector processing technology of the present invention comprises:

[0034] Step 1: Glue the TPT backplane 3 on the photovoltaic cell board. The function of the TPT backplane 3 is to protect and support the cells, and it has reliable insulation, water resistance, and aging resistance. Then, on the TPT backplane 3 Place a layer of thermal adhesive film, place the heat conducting plate 1 on the thermal adhesive film to form a composite plate, and then place the whole on the conveyor belt;

[0035] Step 2: After being transported by the conveyor belt, the combined board enters the first vacuum lamination chamber, where the thermal adhesive film is melted to stick the photovoltaic cell board and the heat conduction plate 1 together;

[0036] Step 3: Move the conveyor belt assembly plate from the first vacuum chamber to the operating table, place the heat conduction tube on the heat conduction plate 1, place a thermal adhesi...

Embodiment 2

[0045] Such as Figure 1-5 Shown, the photovoltaic heat collector processing technology of the present invention comprises:

[0046]Step 1: Glue the TPT backplane 3 on the photovoltaic cell board. The function of the TPT backplane 3 is to protect and support the cells, and it has reliable insulation, water resistance, and aging resistance. Then, on the TPT backplane 3 Place a layer of thermal adhesive film, place the heat conducting plate 1 on the thermal adhesive film to form a composite plate, and then place the whole on the conveyor belt;

[0047] Step 2: After being transported by the conveyor belt, the combined board enters the first vacuum lamination chamber, where the thermal adhesive film is melted to stick the photovoltaic cell board and the heat conduction plate 1 together;

[0048] Step 3: Move the conveyor belt assembly plate from the first vacuum chamber to the operating table, place the heat conduction tube on the heat conduction plate 1, place a thermal adhesiv...

Embodiment 3

[0057] Such as Figure 1-5 Shown, the photovoltaic heat collector processing technology of the present invention comprises:

[0058] Step 1: Glue the TPT backplane 3 on the photovoltaic cell board. The function of the TPT backplane 3 is to protect and support the cells, and it has reliable insulation, water resistance, and aging resistance. Then, on the TPT backplane 3 Place a layer of thermal adhesive film, place the heat conducting plate 1 on the thermal adhesive film to form a composite plate, and then place the whole on the conveyor belt;

[0059] Step 2: After being transported by the conveyor belt, the combined board enters the first vacuum lamination chamber, where the thermal adhesive film is melted to stick the photovoltaic cell board and the heat conduction plate 1 together;

[0060] Step 3: Move the conveyor belt assembly plate from the first vacuum chamber to the operating table, place the heat conduction tube on the heat conduction plate 1, place a thermal adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com