Process for treating filter of radioactive waste liquid filter treatment device

A radioactive waste liquid and processing device technology, which is applied in radioactive purification, nuclear engineering, etc., can solve problems such as hidden safety hazards, low operating efficiency, and the impact of exposure dose, and achieve the effects of convenient operation, improved operating efficiency, and protection of radiation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a radioactive waste liquid filter treatment device, including a hoisting unit, a drying unit and a packaging unit,

[0034] The hoisting unit includes a shielding container 6, a gripper and a sling 11. The shielding container 6 is a cylindrical structure with an open bottom and a closed top. The shielding container 6 can adopt a circular cylinder structure or a square cylinder structure, which can be selected according to the external shape of the filter 3, as long as the filter 3 can be accommodated inside the shielding container 6, the outer wall of the filter 3 is preferably the same as the shielding container 6. There is a certain gap between the inner walls of the filter 3 to prevent the outer wall of the filter 3 from contacting the inner wall of the shielding container 6 during the hoisting process, increasing the resistance, or affecting the positioning of the filter 3. Here, the shielding container 6 with a cylindrical structure is selec...

Embodiment 2

[0038]Further improvement on the basis of Embodiment 1, a bottom plate 6a is provided at the opening of the bottom end of the shielding container 6, and the drawer structure of the bottom plate 6a is arranged on the bottom end of the shielding container 6, and the drawing direction of the bottom plate 6a is in line with the shielding container 6 The axial direction of the shielding container 6 is vertical, that is, the base plate 6a enters and exits the shielding container 6 along the radial direction of the shielding container 6; , the bottom plate 6a is used to provide support for the filter 3 located in the shielding container 6 . Specifically, the structure of the bottom plate 6a is adapted to the radial cross-sectional shape of the shielding container 6, and a notch is provided on the side wall near the bottom of the shielding container 6, and the inner wall near the bottom of the shielding container 6 extends circumferentially. A guide groove is provided, and after the b...

Embodiment 3

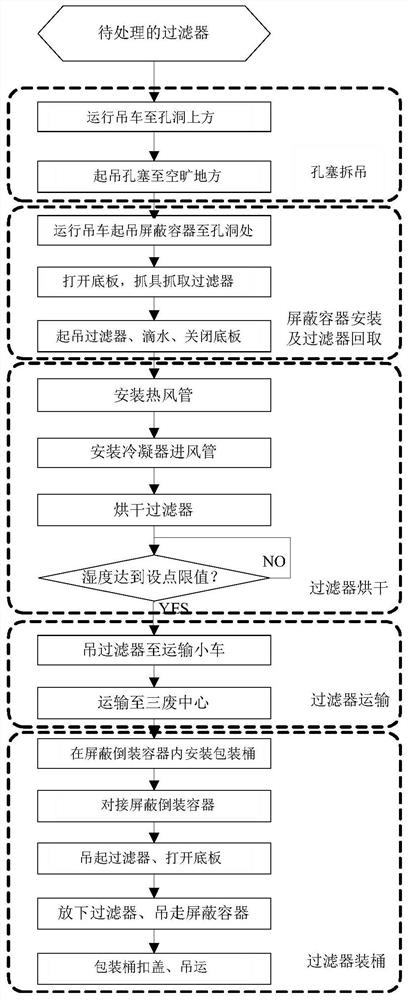

[0044] This embodiment provides a radioactive waste liquid filter treatment process, specifically using the device provided in Embodiment 2 to operate, such as figure 1 As shown, the processing steps are as follows:

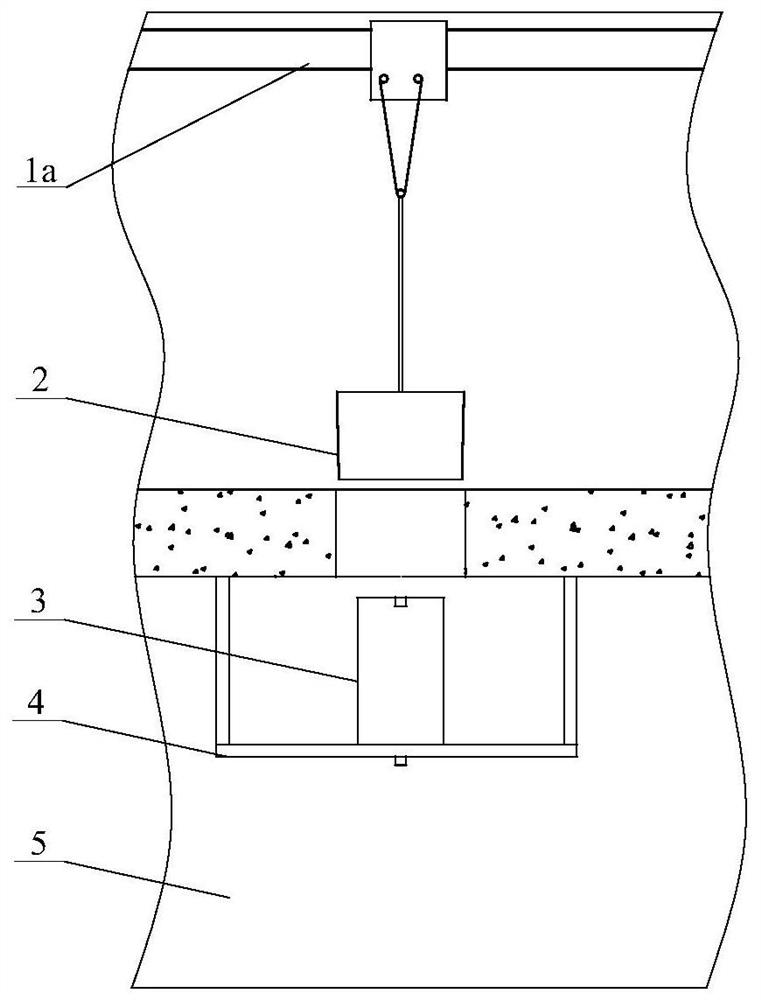

[0045] Step 1, the filter 3 containing impurities in radioactive waste liquid is installed on the filter holder 4 in the waste liquid storage tank 5, the top of the storage tank 5 is set in a hole directly above the filter 3, and the hole plug 2 is passed through the hole Sealing; when using the device provided by the present invention to handle the operation, at first, install the sling 11 and the grabber on the crane 1a, run the crane 1a to the directly above the hole, make the grabber align with the connector on the hole plug 2, and the lower sling 11 and control the gripper to grab the connecting piece, lift the hole plug 2 and transport it to another open location for storage, such as figure 2 shown.

[0046] Step 2, run the crane 1a, grab the quick conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com