Cutting tool wear monitoring method based on evolutionary data clustering analysis

A tool wear and cutting tool technology, applied in the direction of manufacturing tools, measuring/indicating equipment, instruments, etc., can solve the problems of poor practicability and achieve good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

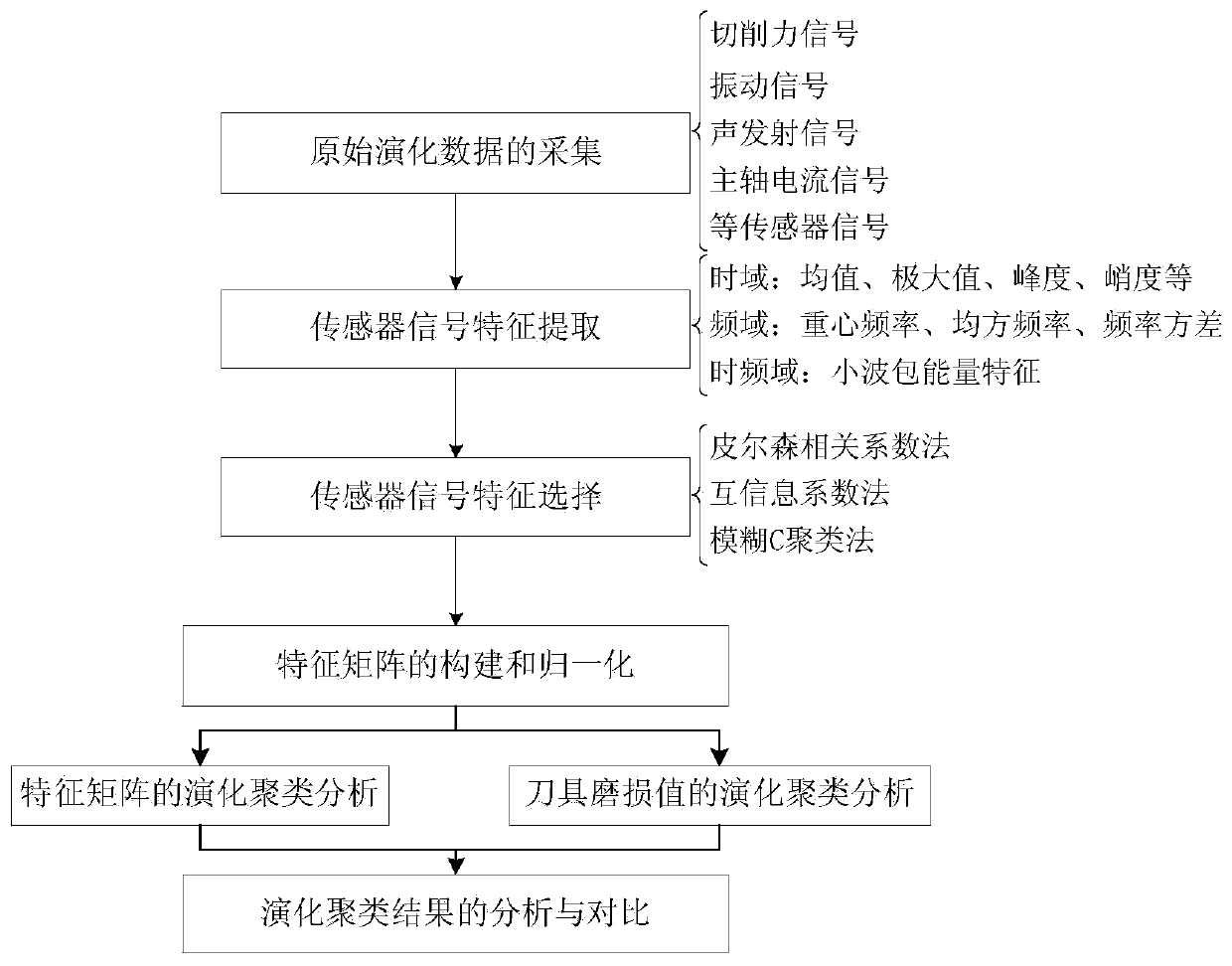

Method used

Image

Examples

Embodiment Construction

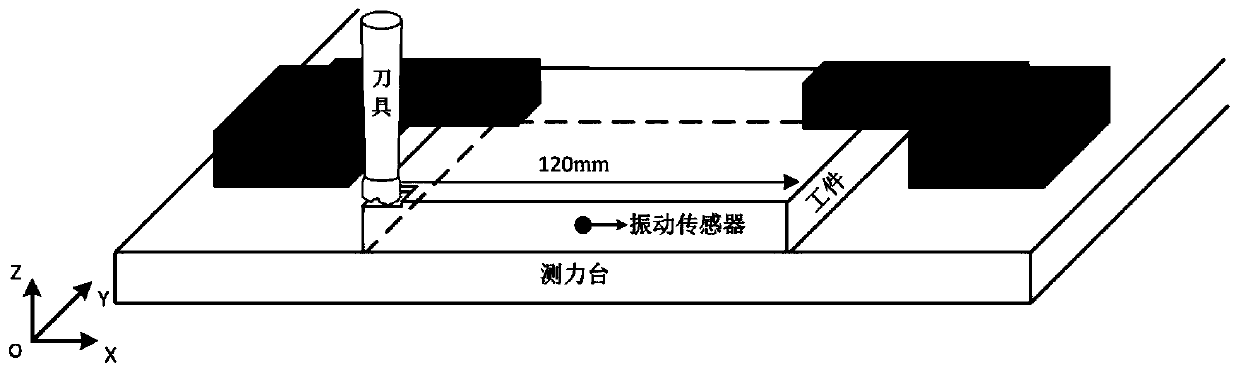

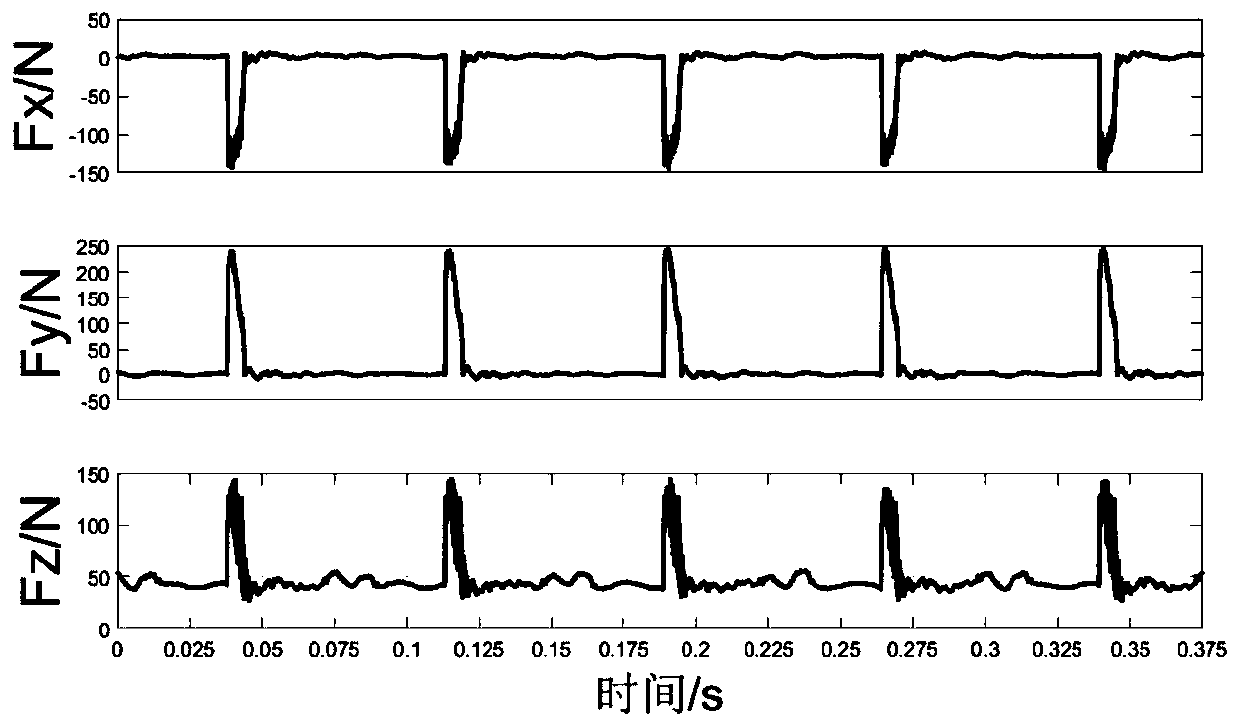

[0032] refer to Figure 1-5 . In the present invention, the force sensor and the vibration sensor are taken as examples, the machine tool is a five-axis CNC milling machine, the milling cutter is a single-tooth insert cutter, the workpiece material is GH4169 superalloy, and the size is 196mm×120mm×16mm, to illustrate cutting tools based on superalloy materials The specific steps of collection, processing, selection process and cluster analysis of wear evolution data.

[0033] Step 1. Collection of original evolution data.

[0034] Install the force measuring platform on the workbench of the five-axis CNC milling machine, fix the workpiece material on the force measuring platform by using the clamp composed of the pressure plate and the pad, install the vibration sensor on the side of the workpiece, and use the lower left corner of the workpiece as the processing origin for tool setting and processing The route cuts from left to right along the length of the workpiece, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com