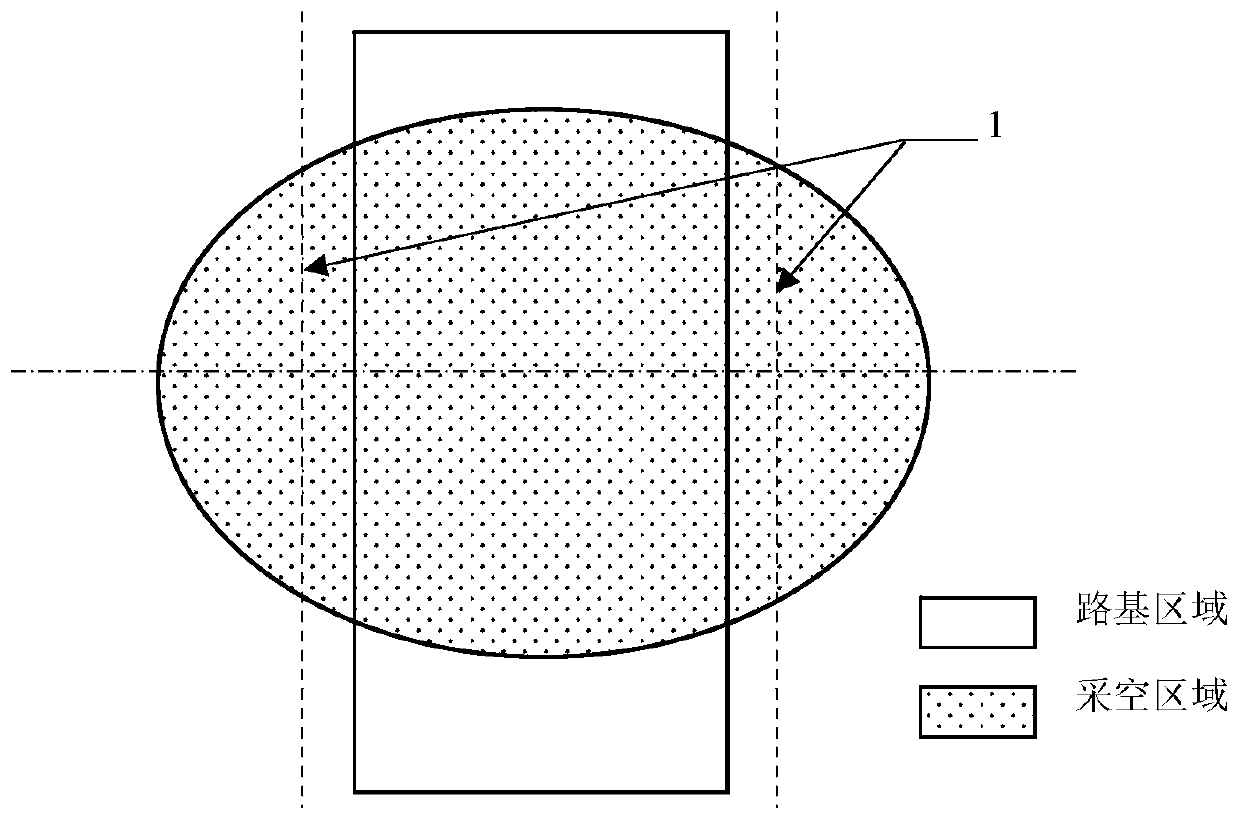

Controllable mould bag grouting method for reinforcing roadbed in underlying goaf

A goaf, controllable technology, applied in roads, roads, soil protection, etc., can solve the problems of uncontrollable flow of grouting materials, accumulation effect of plugging accidents, difficult rapid accumulation of grout, etc., to reduce dilution effect , Guaranteed coagulation quality, convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

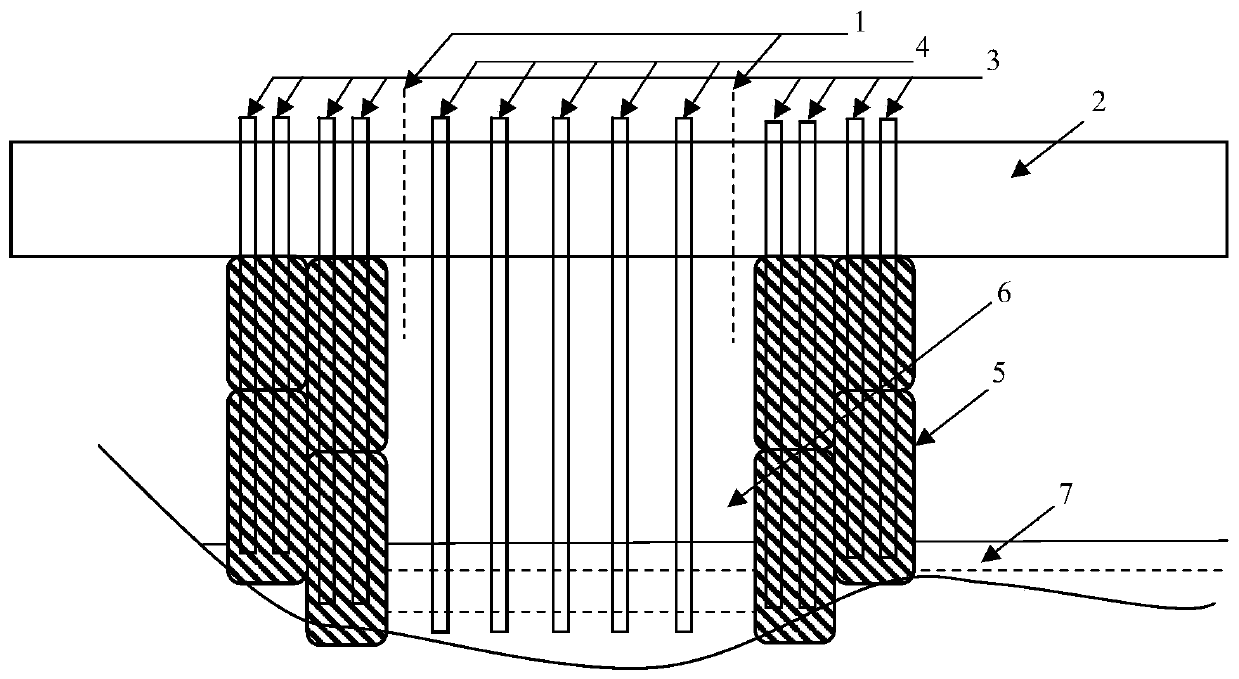

[0067] Such as image 3 As shown in Fig. 1, the non-collapsed connected cavity-type goaf subgrade reinforcement treatment, according to the on-site determination of the reinforcement design parameters, the first exploration of the goaf, and then on-site distance measurement and laying out, to determine the location of the curtain hole and grouting hole drilling, Drill holes according to the parameters of the design plan, the distance between curtain holes is 2m, and the distance between grouting holes is 6m. The cement mortar is M7.5 cement mortar mixed by a mixing station. The mix ratio of water: sand: cement is 240:1504:260, and the sand is fine The sand and cement are ordinary silicon No. 42.5 cement produced by Linyi Cement Factory, and the water level is tap water; the ratio of water for cement filling slurry: cement: fly ash is 0.8:0.4:0.6, and the fly ash adopts the national first-class standard fly ash. The cement is bulk cement 42.5 silicate cement made by Yizhou Ceme...

Embodiment 2

[0069] A film bag curtain forming device, in which a galvanized pipe 9 is placed in the middle of a mold bag 11, and a plurality of strings 12 are used to bind the film bag 11 on the outside of the galvanized pipe 9, and the side walls of the galvanized pipe 9 are evenly opened There are small holes 10, and the inside of the galvanized pipe 10 is provided with a grouting pipe 3, which can simultaneously take into account the lowering of the film bag 11 and the forming effect of the curtain wall 5 after the mold bag 11 is grouted.

[0070] The key to the controllable grouting technology in Example 1 is: the lowering of the mold bag 11 and the opening of the mold bag 11 by grouting to form the curtain wall 5. Using the above design, the film bag 11 can be accurately lowered to the target position, and then After grouting, it can be fully expanded to form an effective curtain wall 5, so as to achieve the purpose of "reducing the dilution effect of groundwater on the grout, prevent...

Embodiment 3

[0073] A film bag curtain forming device, in which a galvanized pipe 9 is placed in the middle of a mold bag 11, and a plurality of strings 12 are used to bind the film bag 11 on the outside of the galvanized pipe 9, and the side walls of the galvanized pipe 9 are evenly opened There are small holes 10, and the inside of the galvanized pipe 10 is provided with a grouting pipe 3, which can simultaneously take into account the lowering of the film bag 11 and the forming effect of the curtain wall 5 after the mold bag 11 is grouted.

[0074] The key to the controllable grouting technology in Example 1 is: the lowering of the mold bag 11 and the opening of the mold bag 11 by grouting to form the curtain wall 5. Using the above design, the film bag 11 can be accurately lowered to the target position, and then After grouting, it can be fully expanded to form an effective curtain wall 5, so as to achieve the purpose of "reducing the dilution effect of groundwater on the grout, prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com