A kind of preparation technology of wear-resisting fireproof cloth

A preparation process and cloth technology, which is applied in the field of preparation of wear-resistant and fireproof cloth, can solve the problems of ineffective real-time temperature detection, and achieve the effect of preventing discoloration from disappearing and content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

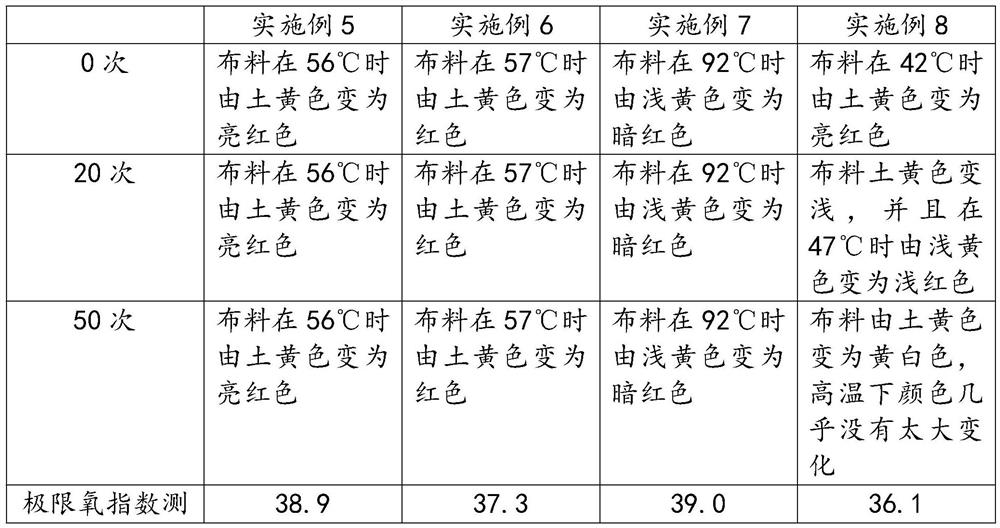

Examples

Embodiment 1

[0022] The concrete preparation process of porous polybenzamide phosphate fiber is as follows:

[0023]① Weigh 27.6g of glycerin and add it to 27mL of ether, stir and mix to form a transparent dilute solution, then add 46.5g of polyisocyanate glue dropwise to the reaction vessel at room temperature, and stir for 4-5 hours after the addition is complete to obtain a polymer solution; ②Heat the polymer solution to 65-70°C, then add paraffin to it, stir and dissolve in the polymer solution, wherein the polymer solution and paraffin are mixed according to the mass ratio of 1:0.1 to obtain the spinning solution; ③Through Spin the spinning solution by an electrospinning machine to obtain polyphenylamide phosphate composite fiber; ④ Add polyphenylamide composite fiber to 80°C hot water and cook for 5-10 minutes, remove it, then dry it, and Add the dried fibers to 80° C. hot water for cooking for 5-10 minutes, take them out, repeat the cooking for 6-7 times, and then dry them to obtain...

Embodiment 2

[0025] The specific preparation process of polybenzamide phosphate composite fiber filament is as follows:

[0026] ① Weigh 27.6g of glycerin and add it to 27mL of ether, stir and mix to form a transparent dilute solution, then add 46.5g of polyisocyanate glue dropwise to the reaction vessel at room temperature, and stir for 4-5 hours after the addition is complete to obtain a polymer solution; ② The polymer solution is spun by an electrospinning machine to obtain polyphenylamide phosphate composite fiber filaments.

Embodiment 3

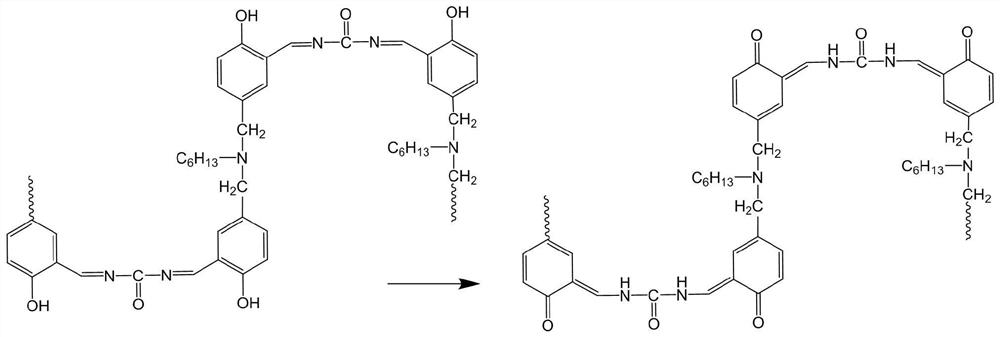

[0028] The specific preparation process of the color-changing polymer is as follows, and the specific reaction structural formula is as follows figure 1 shown;

[0029] Step 1: Add 6g of urea into 80mL of water and stir to dissolve, and at the same time add 24.4g of salicylaldehyde, stir and react at room temperature for 2-3h, and then carry out vacuum distillation to obtain product A;

[0030] Step 2: Mix acetic acid and concentrated sulfuric acid at a volume ratio of 5:1 to form an acid solvent, then add 70mL of the acid solvent into the reaction vessel, cool down to 8-10°C, and add 54g of formaldehyde with a mass concentration of 37% and 6.3g of n-hexylamine, stirred at constant temperature for 10-15min, then added 10g of the product A prepared in step 1 to the reaction vessel, kept the temperature constant for 2-3h, then raised the temperature to 30-35°C and stirred for 8-9h, To obtain a polymer solution, add the obtained polymer solution to ice water, stir and mix for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com