Steel for large-sized wind power fastener and manufacturing method of steel

A technology for large-scale fasteners, applied in the manufacture of tools, metal rolling, temperature control, etc., can solve the problems of inconsistency in area shrinkage of finished products, increase of post-finishing pressure, poor low-temperature impact performance, etc., and achieve hardness differences small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

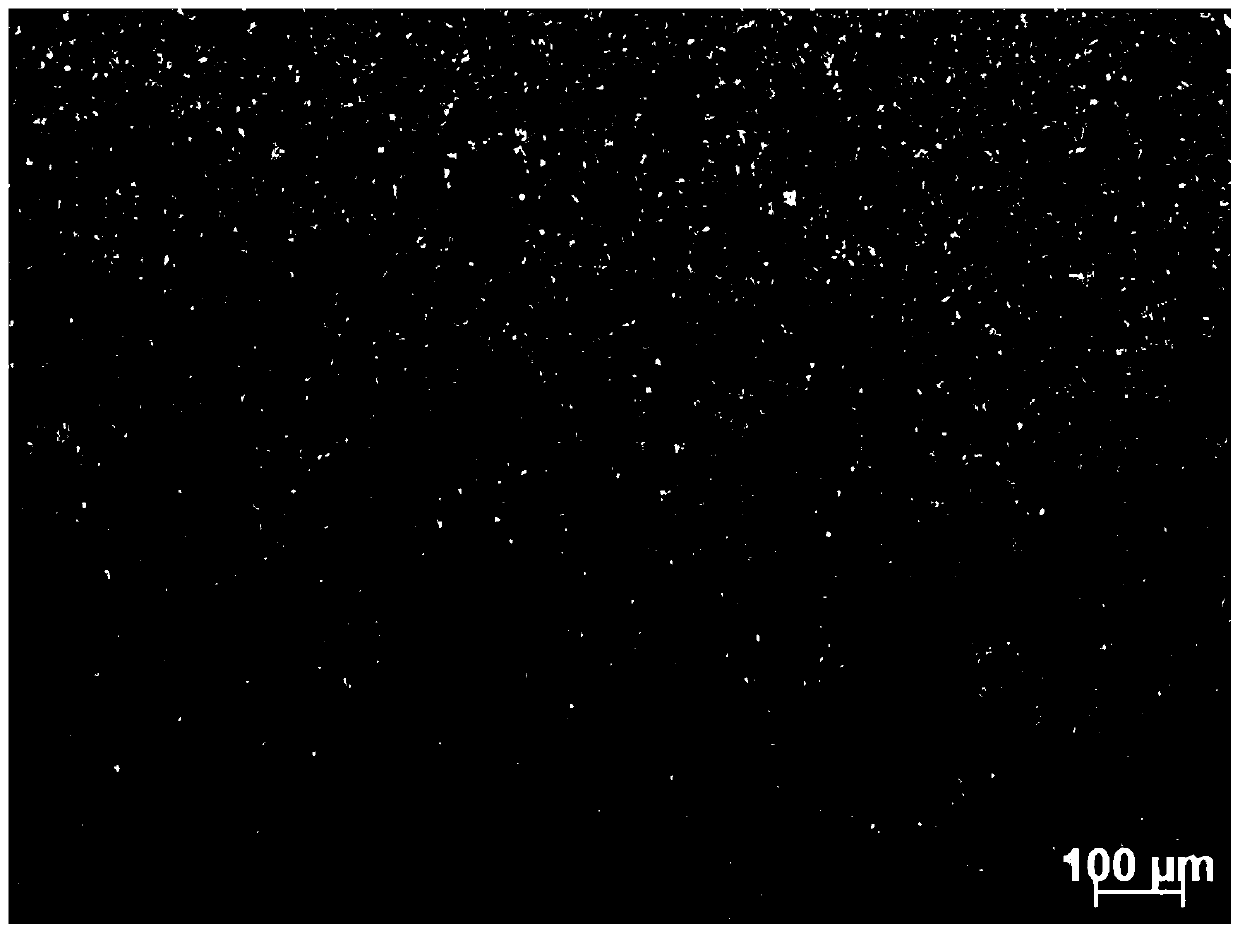

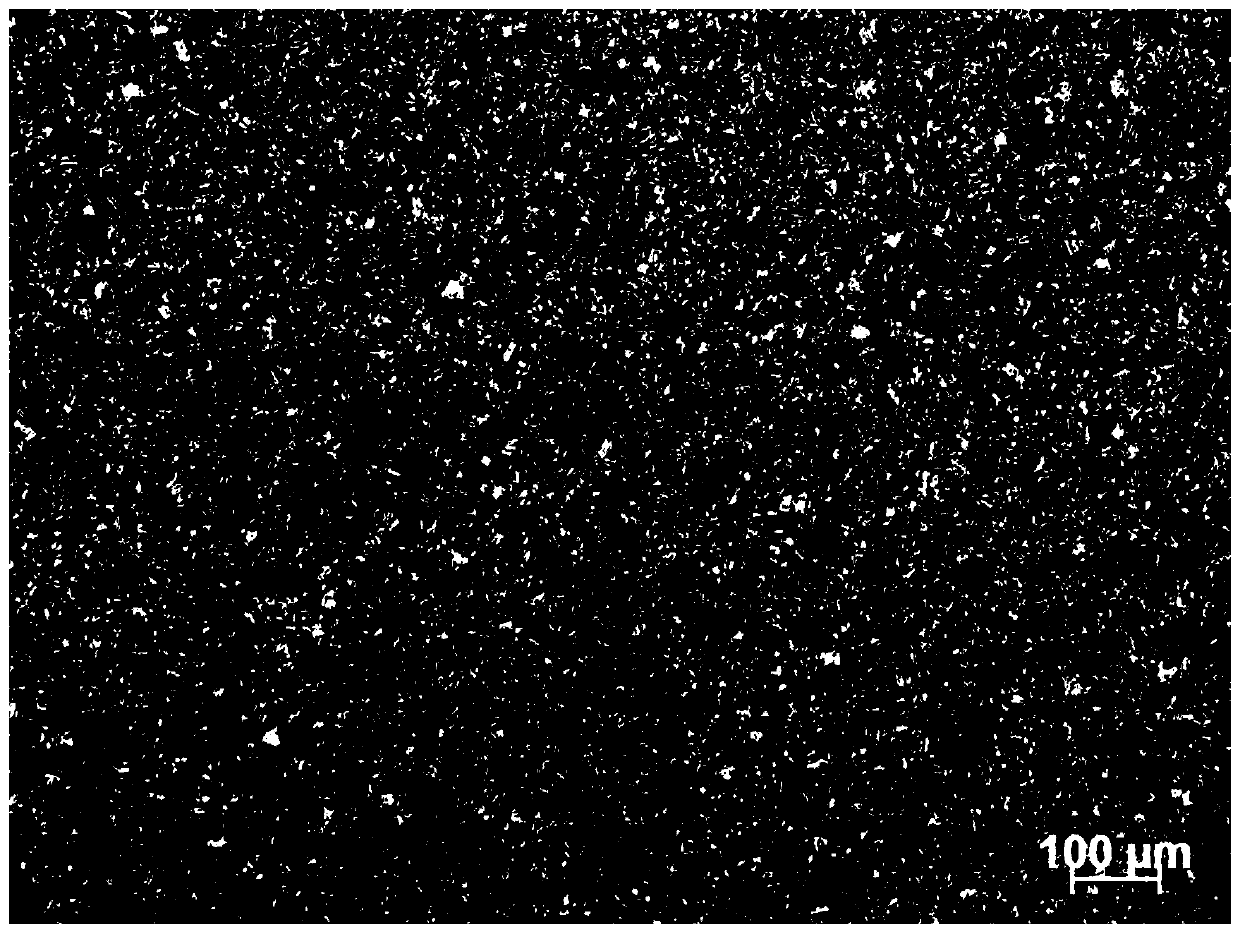

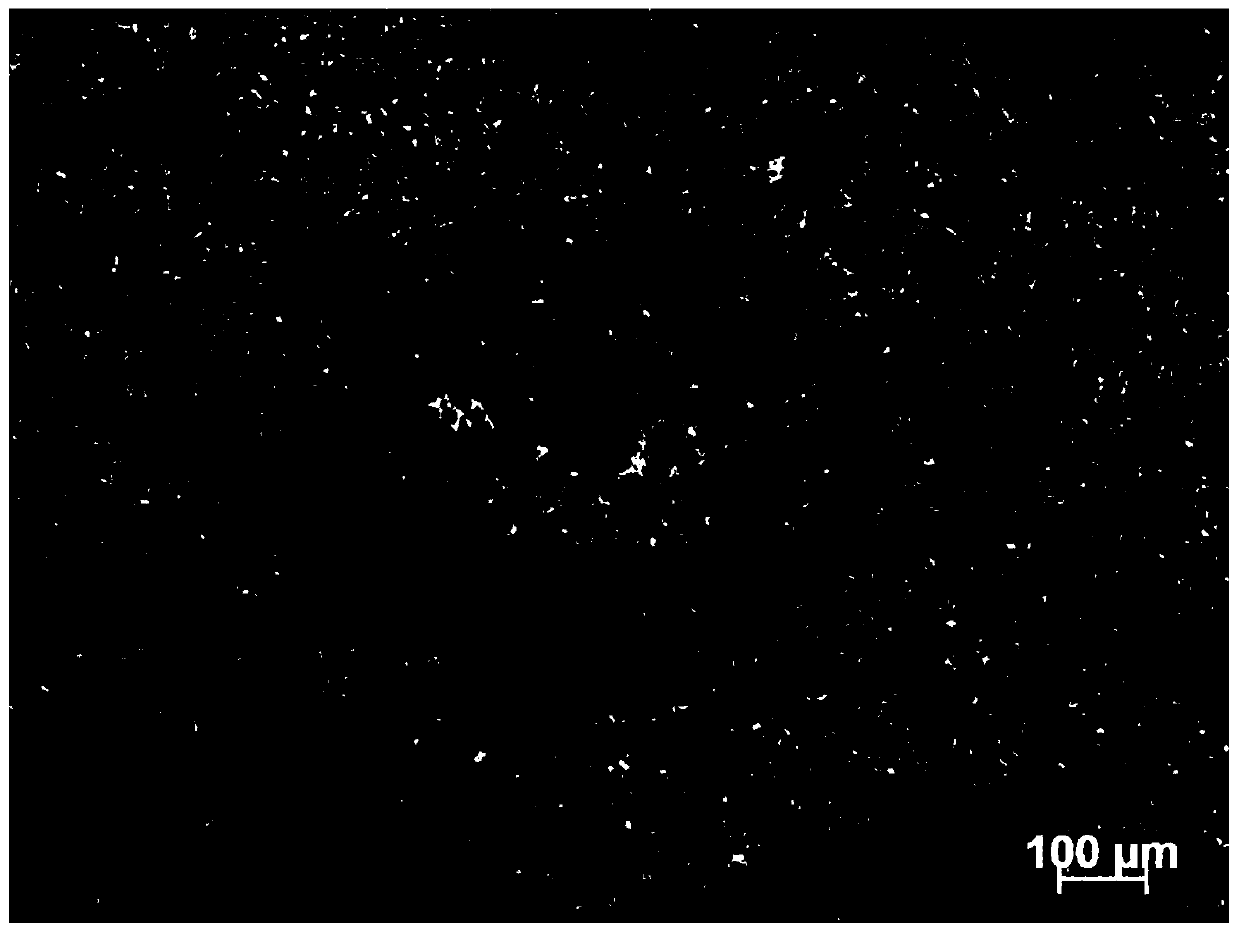

Image

Examples

Embodiment Construction

[0052] The element composition of the present invention contains: C: 0.38-0.45%, Si: 0.20-0.35%, Mn: 0.60-0.80%, P≤0.015%, S≤0.010%, Cr: 0.95-1.20%, Mo : 0.18-0.30%, Ni: 0.10-0.25%, Nb: 0.02-0.08%, Al: 0.020-0.050%, N≤0.008%, the balance is Fe and unavoidable impurities; Permeability formula:

[0053]

[0054] in:

[0055]

[0056] D. i =25.4×(0.171+0.001×C+0.265×C 2 )×(1.000+3.333×Mn)×(1.000+0.700×Si)×(1.000+0.363×Ni)×(1.000+2.160×Cr)×(1.000+3.000×Mo)×(1.000+0.365×Cu)

[0057] b=0.22Di-0.34

[0058] In the formula, x is the end quenching distance, the hardness distribution is J(x), C is the carbon content, Di is the depth from the end to the half martensite (50% martensite), b is the end to the full martensite The depth of the body (100% martensite).

[0059] In order to verify that the limited range of each element in the present invention can achieve technical effects, according to the above element composition requirements, 6 furnaces of the steel for wind powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com