Chalcogenide glass and its preparation method and device

A technology of chalcogenide glass and preparation equipment, which is applied in glass manufacturing equipment, glass furnace equipment, glass forming, etc., which can solve the problems of difficulty in controlling the consistency of composition and performance and low melting efficiency, so as to ensure the consistency of composition and performance , long equipment life, eliminate the effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

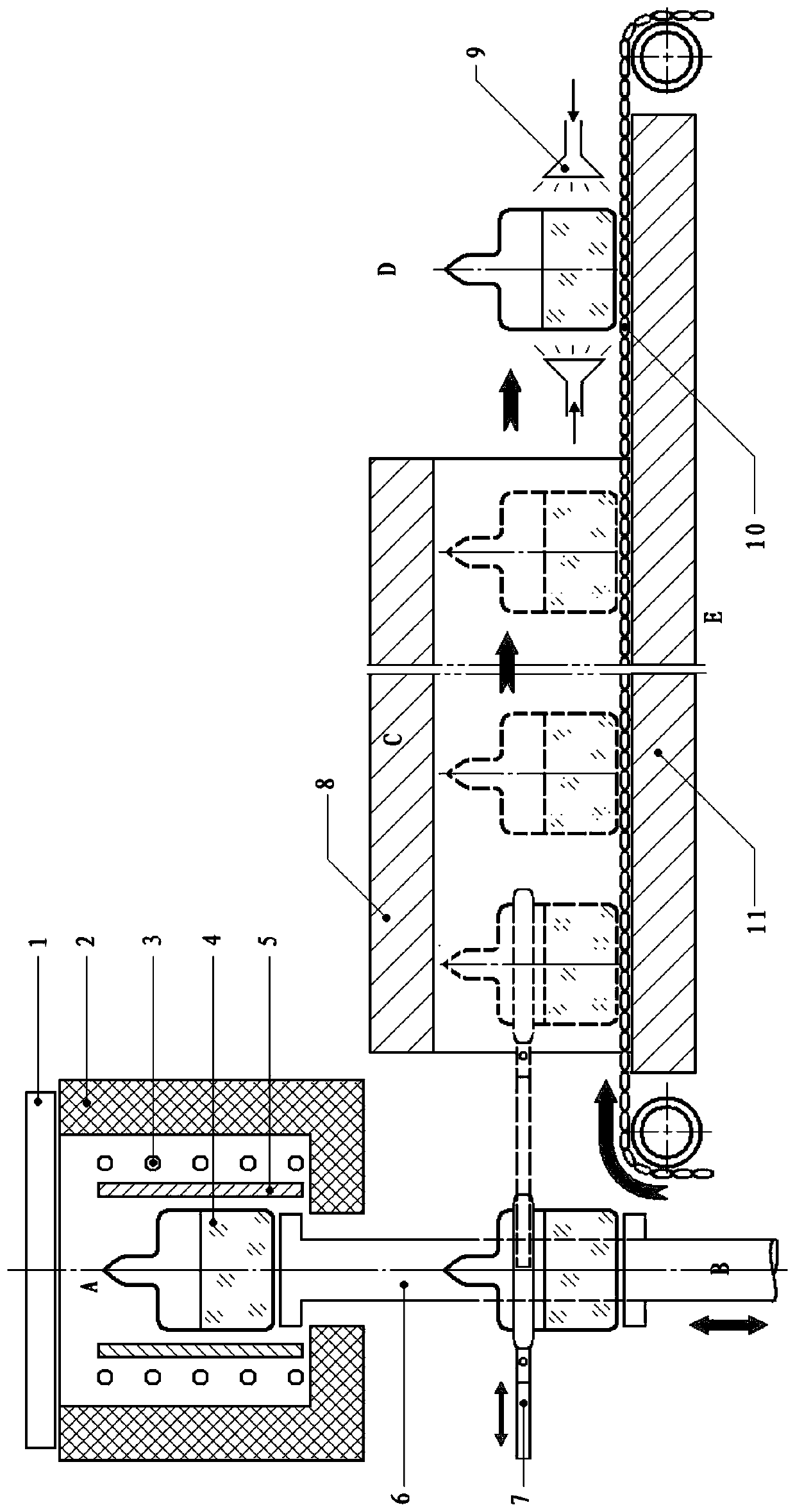

[0035] The present invention provides a preparation device for chalcogenide glass, including a melting module, a lifting module, a homogenizing module, a cooling module, a transmission module and a crucible, wherein the melting module includes a furnace cover, a furnace body, an intermediate frequency induction coil and Induction heating element, the furnace cover and the furnace body constitute a melting cavity, the bottom of the melting cavity is open, the intermediate frequency induction coil is located in the melting cavity, and the intermediate frequency induction coil makes the The heating element is heated by induction; the lifting module includes a lifting rod and a lifting control system, and the lifting module is used to drive the crucible to perform the first movement; the homogenizing module includes a holding furnace and a temperature control system; The transmission module includes a conveyor belt and a speed control system, and the transmission module is used to ...

Embodiment

[0054] This embodiment provides a process for preparing chalcogenide glass using the device for preparing chalcogenide glass provided by the present invention. Chalcogenide glass preparation equipment such as figure 1 shown.

[0055] Purification of ingredients: According to the design ratio, the required chalcogenide glass raw materials are weighed in the anaerobic and anaerobic glove boxes, mixed with the oxygen scavenger to form a batch, and loaded into the quartz glass crucible 4 . The purity of the raw materials used is better than 99.999%, and the particle size of the material is 2-5mm. In this embodiment, the quality of the raw material is 2 kg, and the volume of the crucible is 1.5 liters.

[0056] The quartz glass crucible is evacuated, and the vacuum degree is not more than 10 -3 Pa, and then bake the evacuated quartz glass crucible at 200-400° C. for 3-10 hours to purify the raw materials. After the purification is completed, the quartz glass crucible 4 is vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com