Corrosion-resistant high-performance wrought magnesium alloy and preparation method thereof

A wrought magnesium alloy, high-performance technology, applied in the field of magnesium alloy materials, to achieve the effects of excellent corrosion resistance, easy availability of equipment, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the N 2 +0.15% HFC-125 (vol.%) under the protection of mixed gas, smelt high-purity ZK60 magnesium alloy ingredients according to the normal smelting process (the impurity content of each component is not higher than 1wt.%), after fully dissolving, at 780 ºC Add the Mg-Yb high-purity master alloy (the impurity content is not higher than 1wt.%) with the Yb content of the final smelted alloy design mass percentage content of 2.0%, and use the spiral electromagnetic field to continuously stir for 10 minutes, and then let it stand at 730 ºC after melting Keep it warm for 30 minutes to remove the slag, then pour it out of the furnace and cool it down to room temperature naturally.

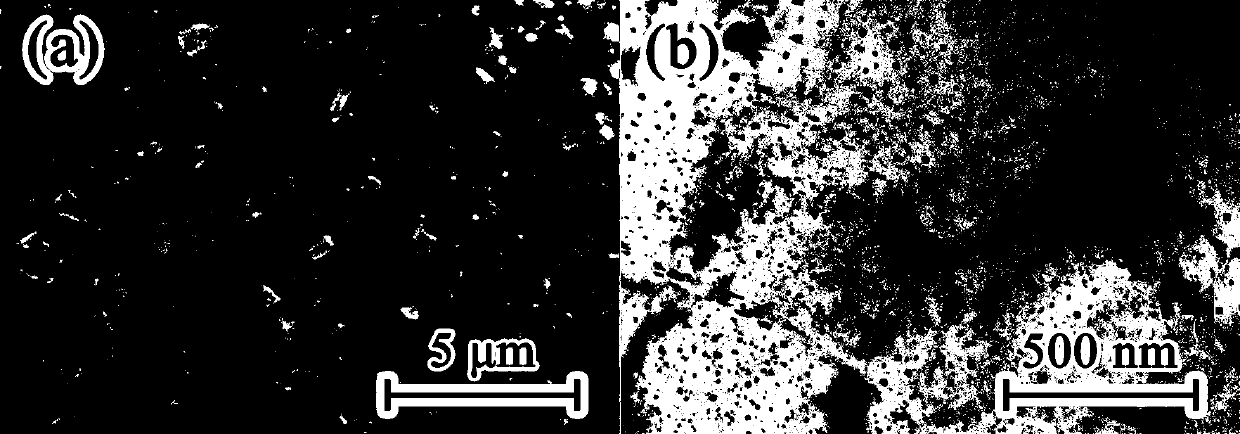

[0029] Subsequently, the ingot was heat-preserved at 450 °C for 24 h in argon, and then water-cooled to room temperature to ensure that the second phase was fully re-dissolved into the matrix and the grains were not overheated or burned.

[0030] Reheat the billet after solut...

Embodiment 2

[0033] In this embodiment, the N 2 +0.15% HFC-125 (vol.%) under the protection of mixed gas, smelt high-purity ZK60 magnesium alloy ingredients according to the normal smelting process (the impurity content of each component is not higher than 1wt.%), after fully dissolving, at 780 ºC Add the Mg-Yb high-purity master alloy (the impurity content is not higher than 1wt.%) whose Yb content is 1.8% of the final smelted alloy design mass percentage content, stir continuously for 10 min using a spiral electromagnetic field, and stand at 730 ºC after melting Keep it warm for 30 minutes to remove the slag, then pour it out of the furnace and cool it down to room temperature naturally.

[0034]Subsequently, the ingot was heat-preserved at 450 °C for 24 h in argon, and then water-cooled to room temperature to ensure that the second phase was fully re-dissolved into the matrix and the grains were not overheated or burned.

[0035] Reheat the billet after solution treatment to 280 °C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com