Method for optimizing structure and performances of N-type Bi2Te3-based thermoelectric material

A kind of thermoelectric material, N-type technology, applied in the direction of metal selenide/telluride, binary selenium/telluride compound, etc., can solve the problems of complex process, high investment cost of production equipment, unsuitable for large-scale commercial production, etc., to achieve Optimization of thermoelectric properties, optimization of thermoelectric and mechanical properties, effect of mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An optimized N-type Bi 2 Te 3 The structure and performance method of the base thermoelectric material, the specific steps are as follows:

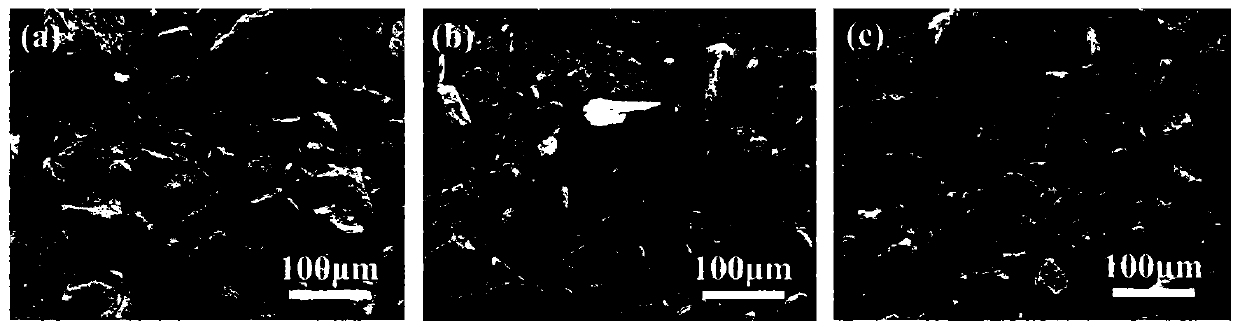

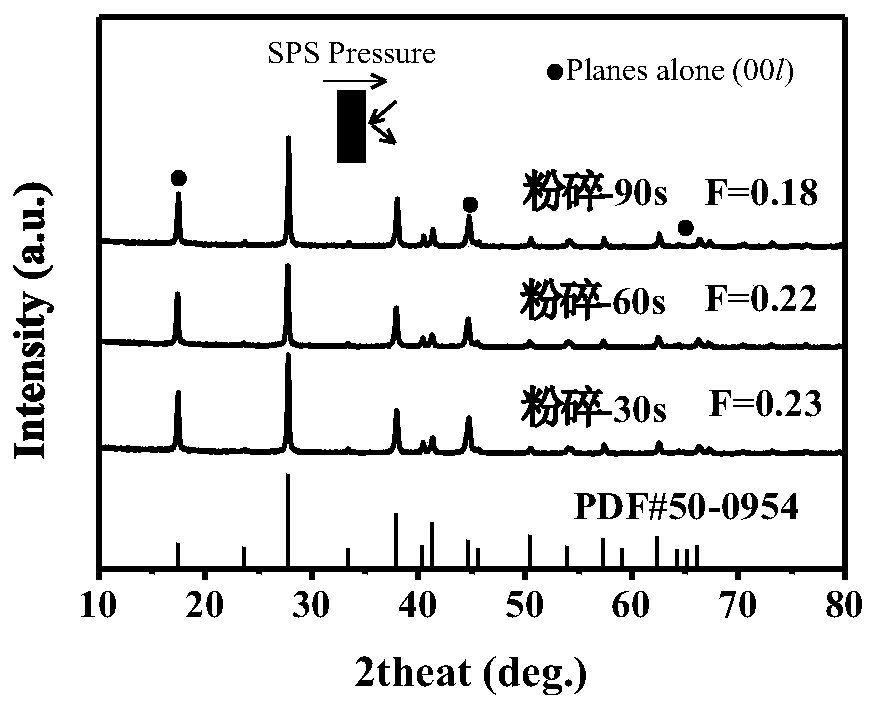

[0027] (1) N-type Bi 2 Te 2.7 Se 0.3 Alloy ingots are continuously crushed on the mechanical pulverizer for 30s, 60s, or 90s respectively, and then sieved with 75 meshes to remove coarse particle materials and make alloy powder;

[0028] Among them, the mechanical pulverizer adopts a small mechanical pulverizer model JYL-C012E; the N-type Bi that is put into the mechanical pulverizer 2 Te 2.7 Se 0.3 The mass of the alloy ingot is 30g, and the grain size is 4mm-6mm.

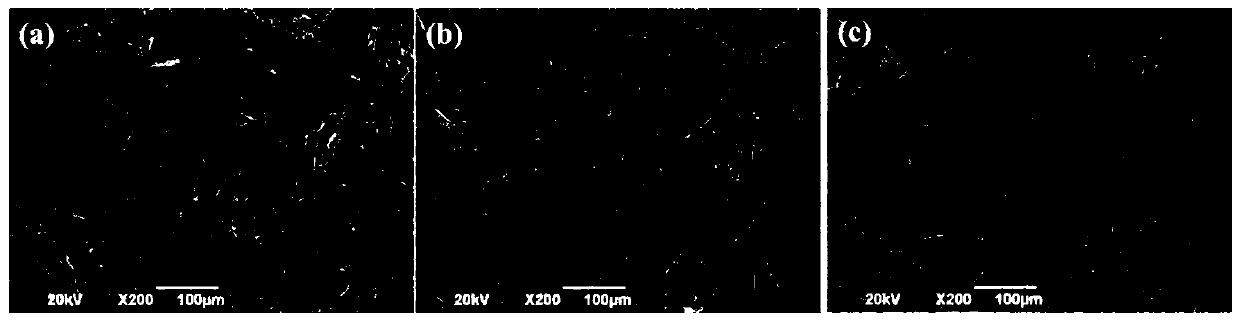

[0029] (2) The prepared N-type Bi 2 Te 2.7 Se 0.3 The alloy powder is placed in a graphite mold, and the bulk thermoelectric material is prepared by SPS sintering technology. Among them, the SPS sintering process is: the sintering pressure is 40MPa, the temperature is raised to 400°C at a heating rate of 50°C / min, and the pressure is kept for 5 minutes, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com