Device and method for auxiliary laser back etching of low-taper glass deep hole by means of liquid flowing coating

An auxiliary laser and coating technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of damage to the surface quality of import and export, low laser absorption efficiency, and large surface chipping caused by blasting, so as to reduce Effects of internal stress accumulation, crack reduction, and taper reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

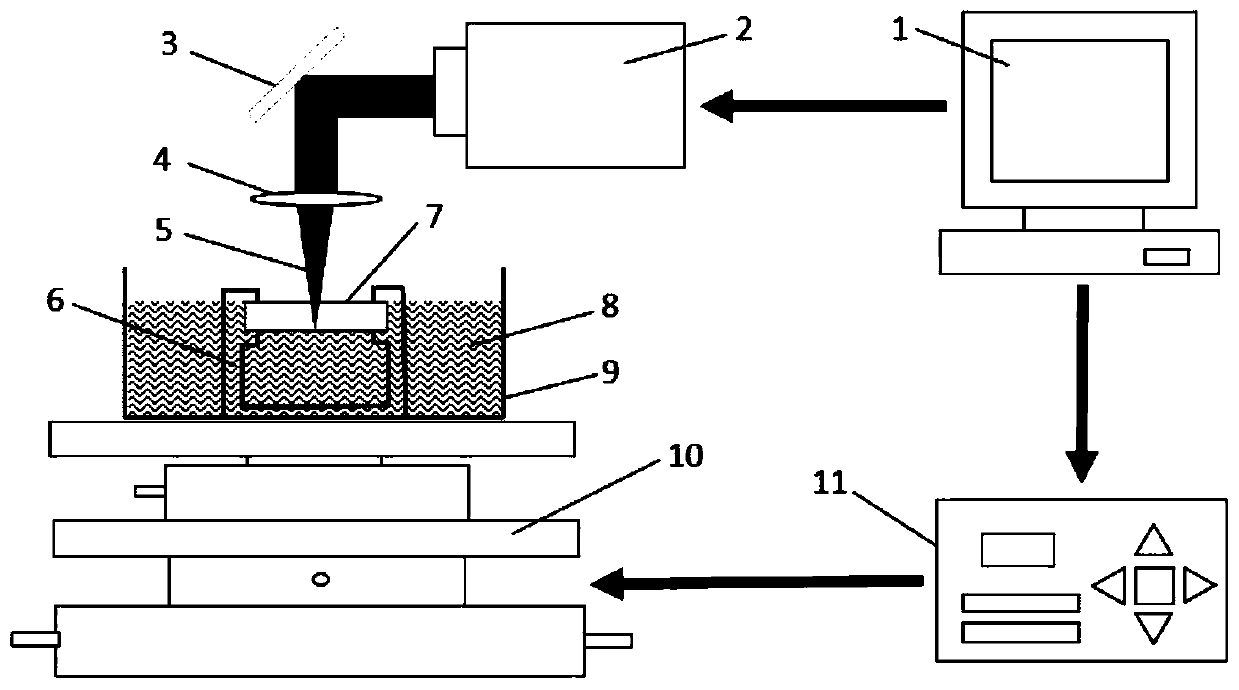

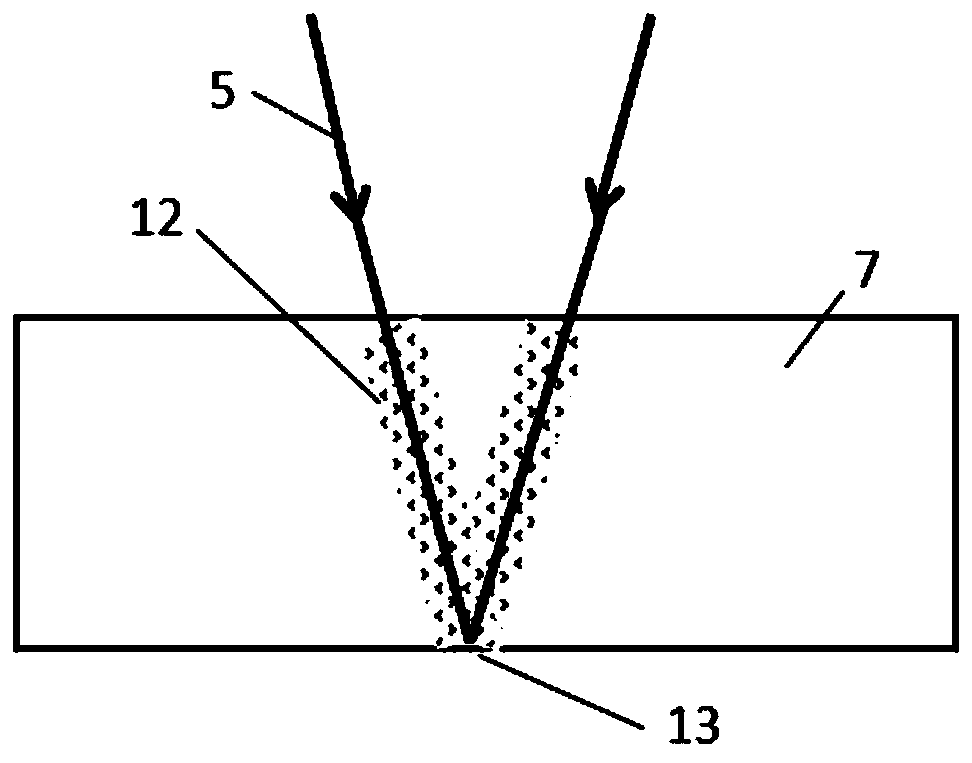

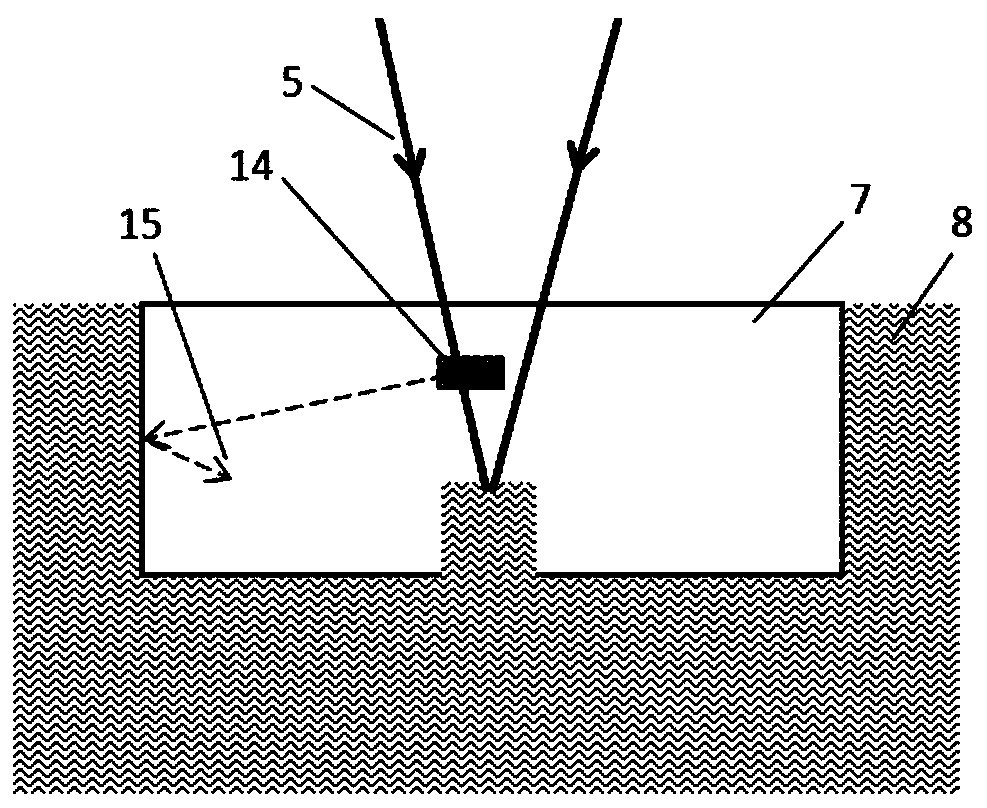

[0034] combined with figure 1 As shown, a device and method for processing low-taper glass deep holes by liquid flow coating assisted laser back wet etching, including a laser chemical composite processing system and a control system. The processing system includes a pulsed laser 2, a mirror 3, a focusing lens 4, a fixture 6, a sample 7, a water tank 9 and the like. The light beam 5 emitted by the laser 2 is irradiated on the lower surface of the sample 7 after being changed by the reflector 3 and focused by the focusing lens 4; the sample 7 is placed horizontally and fixed on the fixture 6; the fixture 6 is placed in the water tank 9 Bottom; the chemical solution 8 in the water tank 9 is close to the upper surface of the sample 7; the control system includes a computer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com