Method for improving large-specification electrically-upset end face concave and promoting grain refining

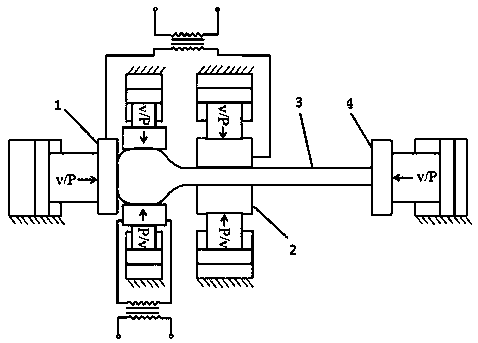

A large-scale, end-face technology, applied in the direction of manufacturing tools, forging presses, forging/pressing/hammer devices, etc., can solve the problems of grain coarsening, uneven material deformation, and large sinking depth of electric upsetting deformed bodies, and achieve The effect of reducing the sinking depth, increasing the degree of uniform refinement, and slowing down the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Both Example 1 and Example 2 use the electric upsetting finite element model to simulate the electric upsetting process. The material is Nimonic80A superalloy, the diameter of the rod is 85mm, the length is 3700mm, and the total stroke of the rod is 2350mm. For this kind of super-sized air valve billet with long rods, a lot of aggregates, and a large variable section ratio, under the condition of ensuring that the electric upsetting process is not unstable, the maximum upsetting force used in the electric upsetting process is 1030KN. , the maximum current is 28.6KA, and the maximum temperature during the electrical upsetting simulation process is 1130°C.

[0046] Example 1

[0047] (1) At 725 seconds, the simulated shapes of electric upsetting of planar anvil electrode and concave anvil electrode are as follows: Figure 6 and Figure 7 As shown.

[0048] At 725 seconds, there is little difference in the simulated temperature of electric upsetting for the two types of...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is only that: the combined form of material reduction and the rounded corner of the aggregate end are 28mm.

[0060] refer to Figure 12 As shown, after the electric upsetting is completed, the diameter of the electric upsetting garlic head using the concave anvil is 198.28mm, and the sinking depth is only 4.64mm. The diameter of the electric upsetting garlic head of the flat anvil is 196.88mm, and the sinking depth is 8.3mm. Compared with the planar anvil, the diameter of the electric upsetting garlic head becomes larger, and the sinking depth decreases.

Embodiment 3

[0062] The difference between this embodiment and embodiment 2 is only that the rounded corner of the aggregate end is 35 mm.

[0063] refer to Figure 13 As shown, after the electric upsetting is completed, the diameter of the electric upsetting garlic head using the concave anvil is 195.12mm, and the sinking depth is 8.27mm. The diameter of the electric upsetting garlic head of the flat anvil is 196.88mm, and the sinking depth is 8.3mm. Compared with the planar anvil, the diameter of the electric upsetting garlic head becomes smaller, and the sinking depth decreases.

[0064] From the experimental results of Examples 1 to 3, it can be seen that the combination of the concave anvil and the material reduction treatment can always reduce the sinking depth. Under the synergistic effect with the concave anvil, with the increase of R1, the diameter of the electric upsetting garlic gradually decreases, the shape transition of the electric upsetting is relatively smooth, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com