Automation device for online machining wheel chamfering

An automatic device and wheel technology, applied in positioning devices, feeding devices, metal processing equipment, etc., can solve the problems of prolonging the total machining cycle, reducing production efficiency, taking a long time, etc., to achieve automatic processing and improve processing efficiency. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

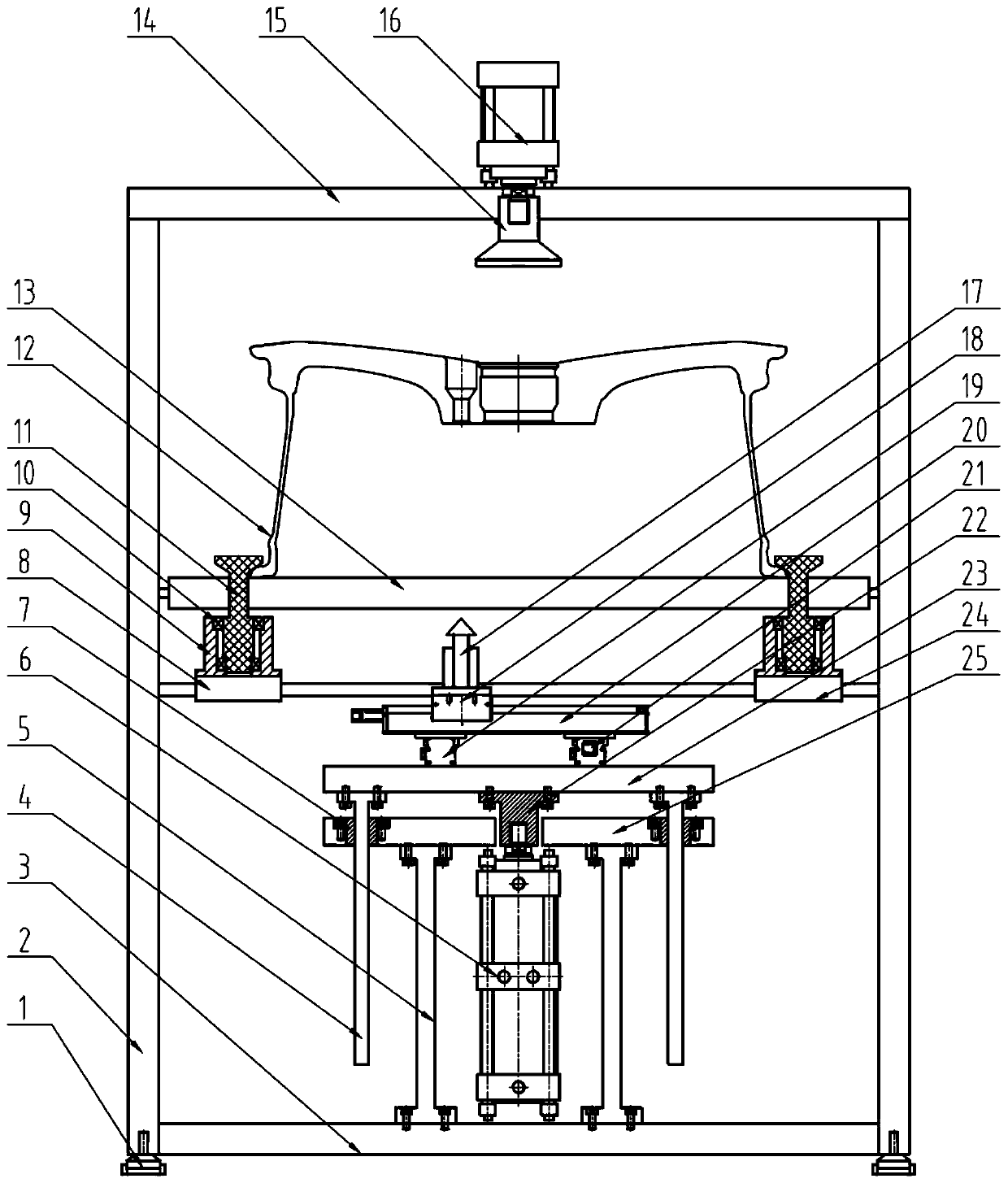

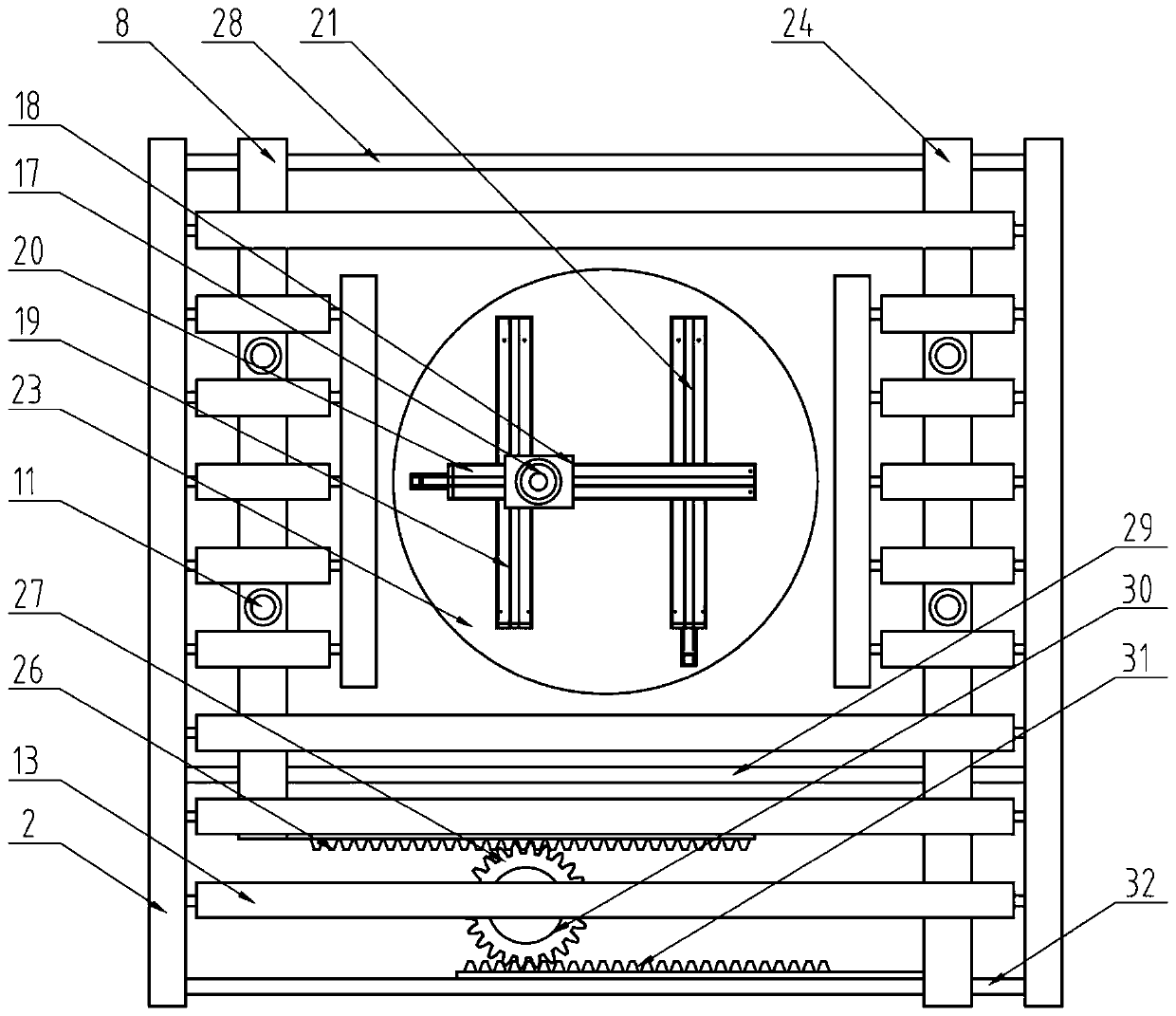

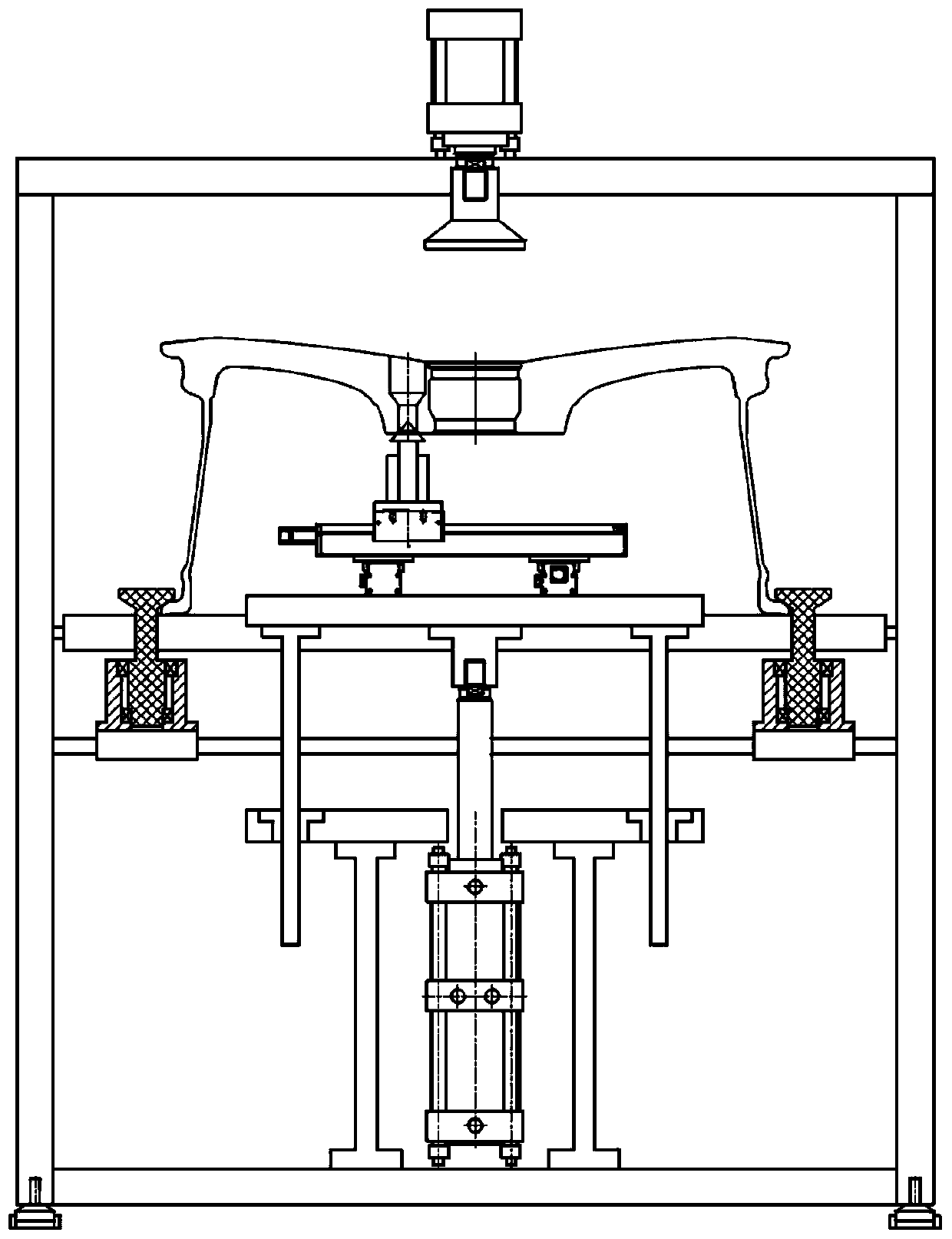

[0062] An automatic device for on-line processing wheel chamfering, which consists of pad iron 1, side vertical plate 2, lower bottom plate 3, guide column I4, pillar 5, cylinder I6, copper sleeve 7, beam I8, shaft sleeve 9, bearing 10, and rotating shaft Body 11, wheel 12, roller body 13, upper base plate 14, smart camera 15, camera bracket 16, pneumatic drill 17, slider 18, linear guide rail 19, linear module I20, linear module II21, connection block 22, circle Plate 23, beam II24, support plate 25, rack I26, gear 27, guide post II28, guide post III29, motor 30, rack II31, guide post IV32 form.

[0063] Such as figure 1 As shown, the automatic device for processing wheel chamfering on-line according to the present invention includes a frame, which has an upper base plate 14, a lower base plate 3 and two side risers 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com