Method of transferring slurry, method of producing polyolefin and use thereof

A slurry and aliphatic hydrocarbon technology, applied in the transfer of slurry, the manufacture and utilization of polyolefins, can solve the problems of inability to transfer slurry, transfer, and completely eliminate clogging, and achieve the goal of preventing clogging and reducing raw material loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121] Examples of the metallocene compound used in the preparation of the metallocene-based solid catalyst include transition metal compounds represented by the following general formula.

[0122] L x m

[0123] (In the formula, M represents a transition metal compound. x represents a numerical value that satisfies the atomic valence of the transition metal M. L is a ligand coordinated with the transition metal, and at least one of L is a ligand having a cyclopentadiene skeleton .)

[0124] As said M, atoms of Groups 3 to 6 of the Periodic Table of Elements (IUPAC 1989) are preferable, and titanium, zirconium, and hafnium are more preferable.

[0125] Ligands having a cyclopentadienyl skeleton as L include (substituted) cyclopentadienyl, (substituted) indenyl, (substituted) fluorenyl, etc. Specifically, cyclopentadienyl, methyl Cyclopentadienyl, tert-butylcyclopentadienyl, dimethylcyclopentadienyl, tert-butylmethylcyclopentadienyl, methylisopropylcyclopentadienyl, trimethy...

Embodiment 1

[0186] (1) Preparation of solid catalyst components

[0187] After replacing the 100 mL flask equipped with the stirrer, dropping funnel, and thermometer with nitrogen, 36.0 mL of toluene and 22.5 mL of titanium tetrachloride were put into this flask, and it stirred. After setting the temperature in the flask to 0° C., 1.88 g of magnesium ethoxide was added at intervals of 30 minutes at this temperature, four times in total, and then stirred at 0° C. for 1.5 hours. Next, 0.60 mL of ethyl 2-ethoxymethyl-3,3-dimethylbutyrate was put into the flask, and thereafter, the temperature in the flask was raised to 10°C. Thereafter, the mixture was stirred at this temperature for 2 hours, and 9.8 mL of toluene was added. Next, the temperature in the flask was raised at a rate of 1.2 K / min, and 3.15 mL of ethyl 2-ethoxymethyl-3,3-dimethylbutyrate was put into the flask at a time of 60° C., and the temperature was raised to 110°C. The components put into the flask were stirred at this t...

Embodiment 2

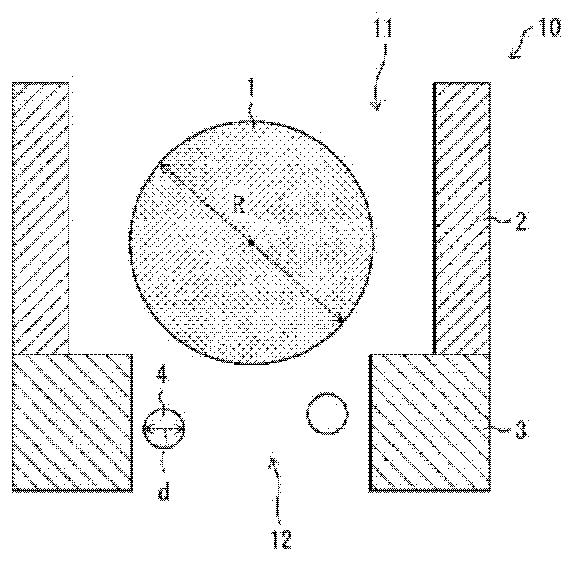

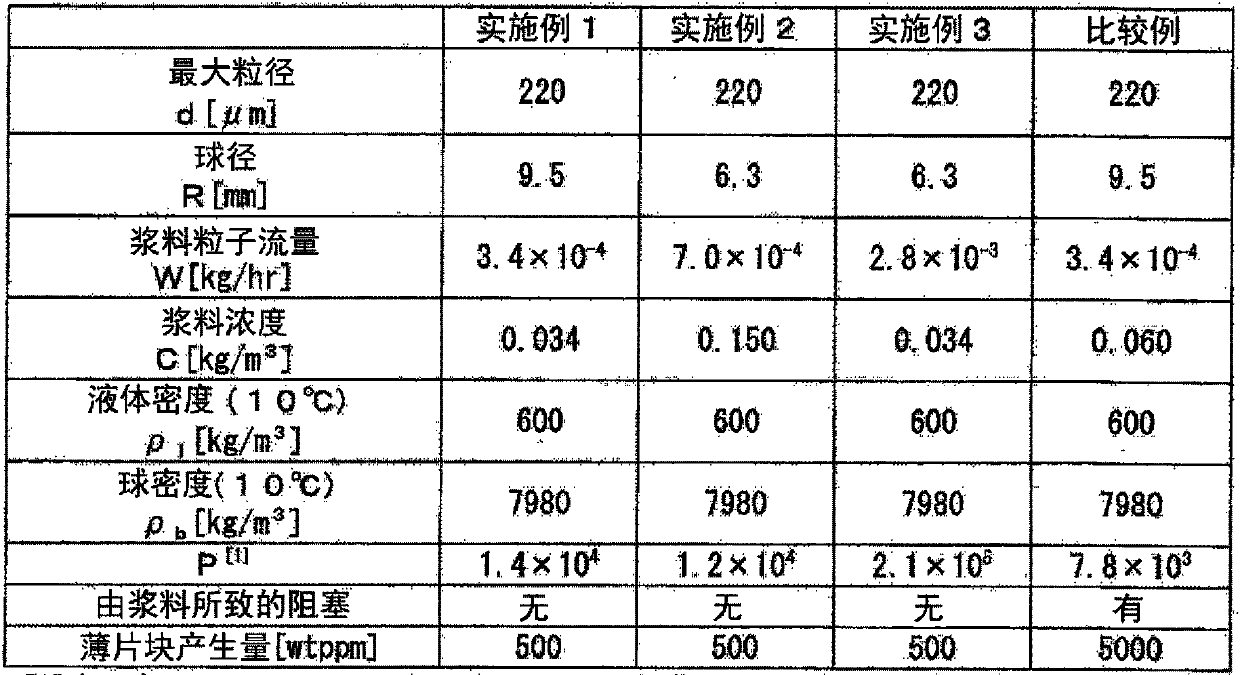

[0200] In the preparation of the above (2) prepolymerization catalyst, the slurry concentration C of the prepolymerization catalyst is adjusted to 0.150kg / m 3 , in the transfer of the above (3-1) slurry, the diameter R of the ball in the plunger pump is set to 6.3 mm, and in the above (3-2) polymerization of polypropylene, the slurry transferred to the first tank The particle flow W of the material is set to 7.0×10 -4 kg / hr, except that, the same operation as in Example 1 was carried out to produce a polypropylene powder. To illustrate, using P=W(ρ l / (ρ b -ρ l )) 0.5 / (C d(d+R)R 0.5 ) calculated value is 1.2×10 4 , satisfying the conditions of formulas (1)-(3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com