Ultrathin solar black silicon wave absorber and preparation method thereof

A technology of sunlight and wave absorbers, applied in the field of silicon materials, can solve the problems of high manufacturing cost, complex structure design, and narrow operating frequency band of electromagnetic wave absorbers, and achieve the effect of low cost, simple structure, and enhanced coupling absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

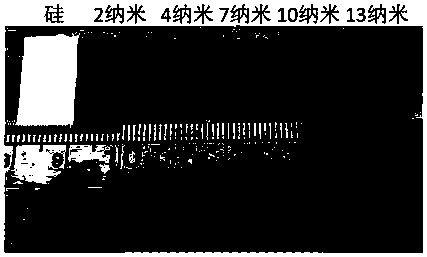

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The ultra-thin solar black silicon absorber of the present invention can be prepared according to the following steps:

[0031] Step 1. Prepare silicon wafers, ultrasonically clean them with absolute ethanol, acetone, and deionized water in sequence, and then dry them to obtain pure silicon wafers;

[0032] Step 2, coating a layer of gold nano film on the surface of the pure silicon wafer by magnetron sputtering technology to obtain SI-Au samples;

[0033] Step 3. Put the SI-Au sample into the muffle furnace, and perform constant temperature and timing heat treatment. The metal film becomes the metal particle layer, and the SI-AuNPs sample is obtained. The metal particles in the metal particle layer are of different sizes and have a radius of 50 nanometers to 200 nanometers;

[0034] Step 4, immerse the SI-AuNPs sample in a new etching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com