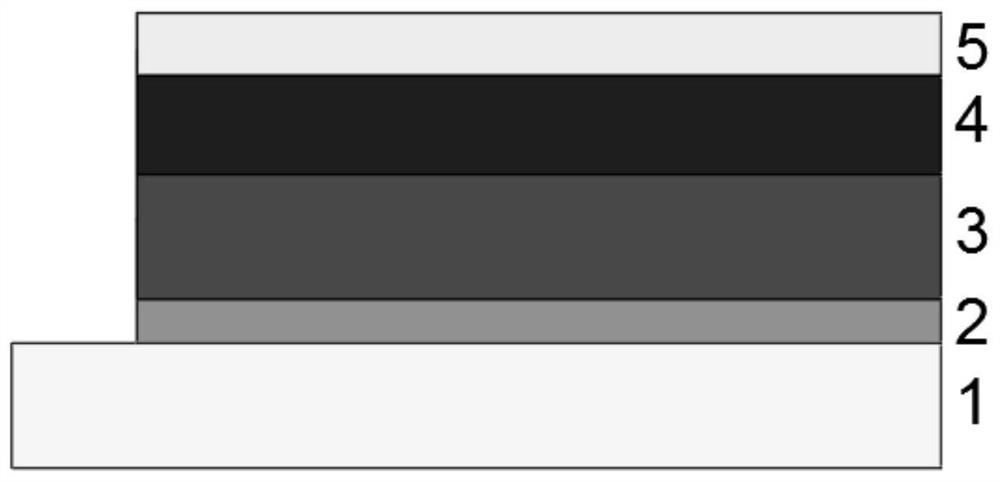

A kind of all-inorganic perovskite solar cell and preparation method thereof

A solar cell and inorganic calcium technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of photovoltaic performance attenuation, poor structural stability of solar cells, etc., achieve less defect state density, excellent air stability, and increase current flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

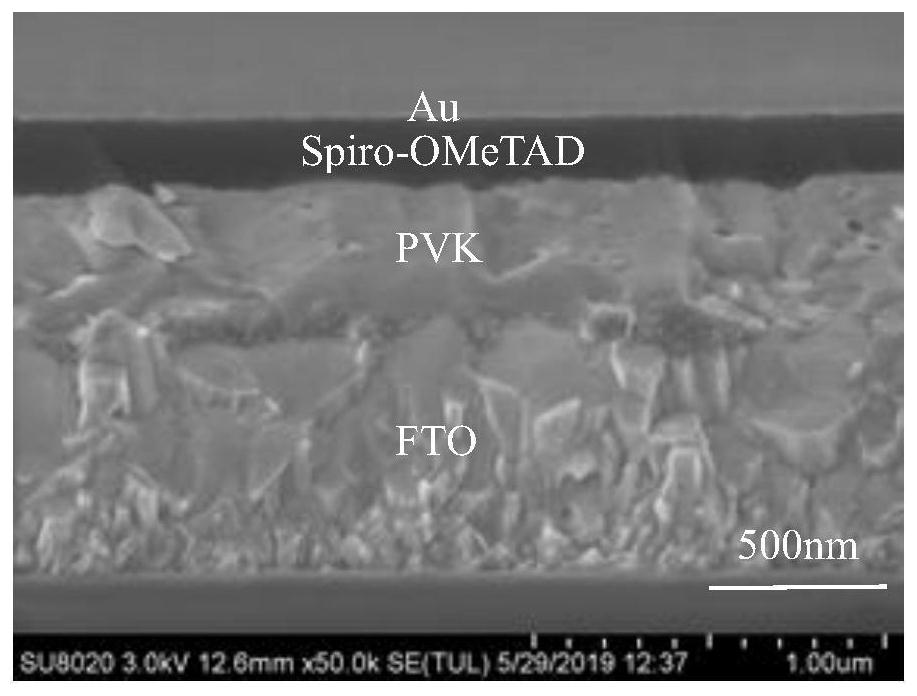

Method used

Image

Examples

Embodiment 1

[0052] First, the complex PbI 2 (DMSO) preparation: 4.84g PbI 2 Dissolve in 15mL DMSO, heat to PbI at 60°C 2 Dissolve completely, and then slowly add about 35mL of toluene to it, and a white precipitate appears. After the precipitate is completely precipitated, filter the precipitate, place the precipitate at room temperature for 3 hours, and then dry it in vacuum at 60°C for 24 hours to obtain PbI 2 (DMSO) complex.

[0053] Second, the complex PbBr 2 (DMSO) preparation: 3.85g PbBr 2 Dissolve in 15mL DMSO, heat to PbBr at 60°C 2 Completely dissolve, then slowly add about 35mL of hot acetone to it, and a white precipitate appears. After the precipitate is completely precipitated, filter the precipitate, place the precipitate at room temperature for 3 hours, and then dry it in vacuum at 60°C for 24 hours to obtain PbI 2 (DMSO) complex.

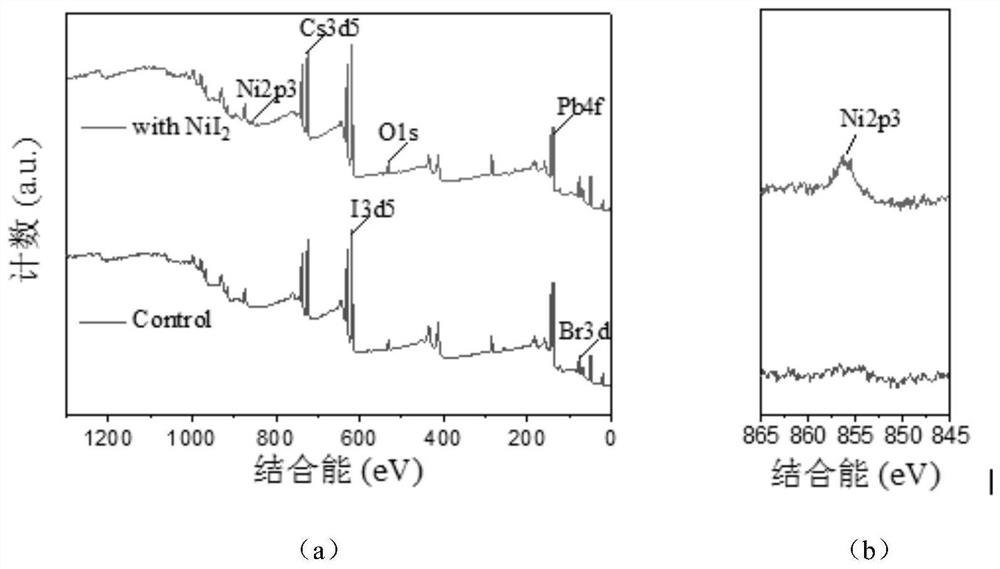

[0054] Third, 0.242g complex PbI 2 (DMSO), 0.200g complex PbBr 2 (DMSO) and 0.234g CsI dissolved in 150μL DMSO and 850μL DMF, where CsP...

Embodiment 2

[0074] In the present embodiment, the thickness of the gold electrode is 70nm, and the content of doped Ni is 0.0028g, in terms of moles, NiI 2 The amount added is CsPbI 2 1% (mol fraction) of Pb content in the Br precursor solution, other steps are identical with embodiment 1. In this example, the efficiency of the inorganic perovskite solar cell was 14.26%.

Embodiment 3

[0076]In this embodiment, the thickness of the gold electrode is 90nm, and the specific spin-coating process of the Ni-doped inorganic perovskite precursor solution is 1000rpm low-speed spin-coating for 10s, and 4000rpm high-speed spin-coating for 30s. Other steps are identical with embodiment 1. In this example, the efficiency of the inorganic perovskite solar cell was 15.77%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com