LPSO-phase strengthening high-damping rare earth magnesium alloy and preparation method thereof

A rare-earth master alloy and rare-earth magnesium technology, which is applied in the field of LPSO phase-strengthened high-damping rare-earth magnesium alloy and its preparation, can solve the problems of poor corrosion resistance, limited application prospects, poor mechanical properties, and low damping performance, and achieve excellent comprehensive mechanics The effect of performance, wide application, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

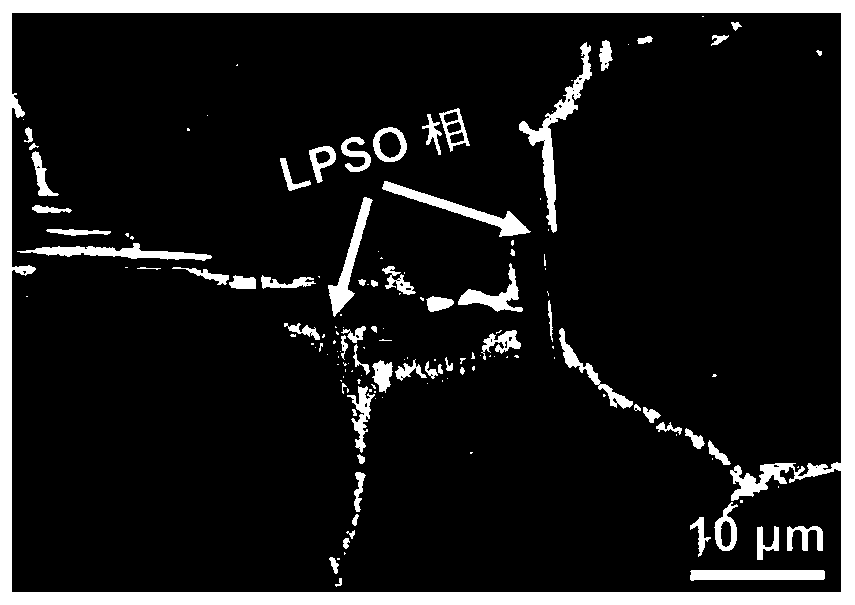

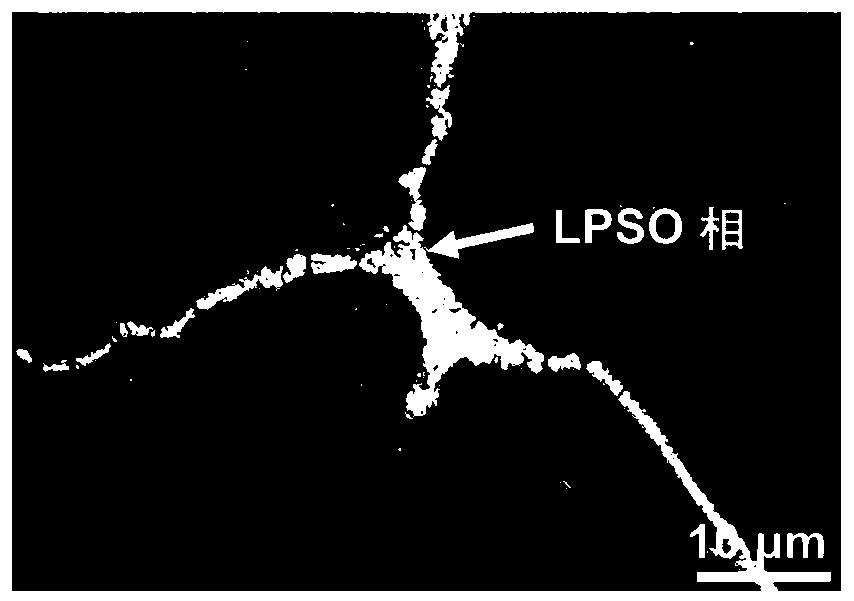

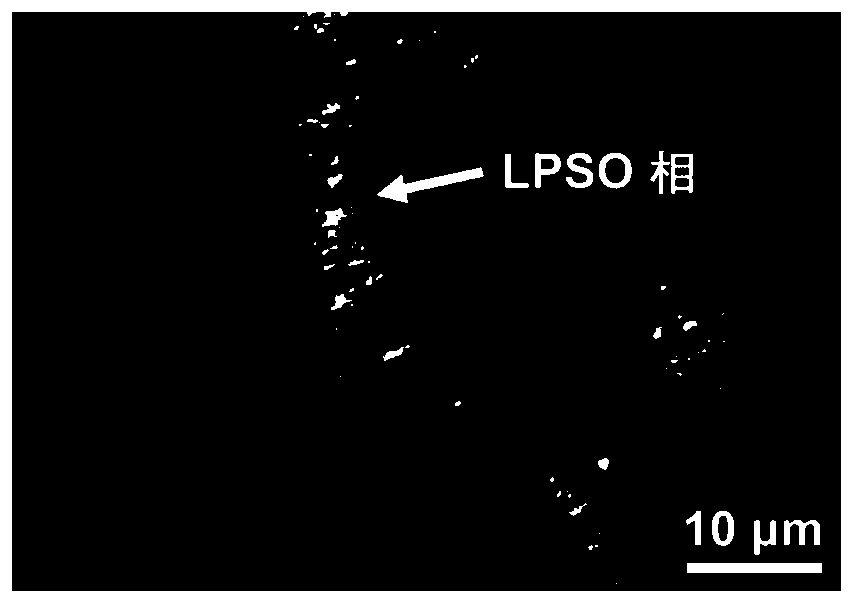

Image

Examples

Embodiment 1

[0040] This embodiment provides an LPSO phase-strengthened high-damping rare earth magnesium alloy. The raw material composition and weight percentage content are: rare earth elements: 2.7%, Zn: 0.8%, Mn: 0.5%, and the balance is Mg.

[0041] The rare earth elements in this embodiment include Y and Ce, the content of Y in the magnesium alloy is 2.2% by weight, and the content of Ce in the magnesium alloy is 0.5% by weight. Wherein the mass ratio of Y and Zn is 2.75.

[0042] The preparation method of the LPSO phase strengthened high damping rare earth magnesium alloy comprises the following steps:

[0043] Step 1: with pure magnesium ingot (more than 99.5wt%), pure Zn ingot (more than 99.5wt%), Mg-25Y master alloy (that is, the composition content of the master alloy is: 25wt% Y, the balance is Mg) and Mg- 20Ce master alloy and MnCl 2 Particles are raw materials, weighed and prepared according to the mass percentage of Y2.2wt%, Ce 0.5wt%, Zn 0.8wt%, Mn 0.5wt%, and the balanc...

Embodiment 2

[0047] This embodiment provides an LPSO phase-strengthened high-damping rare-earth magnesium alloy. The raw material composition and weight percentage content are: rare earth elements: 3.2%, Zn: 1.0%, Mn: 0.6%, and the balance is Mg.

[0048] The rare earth elements in this embodiment include Y and Ce, the content of Y in the magnesium alloy is 2.5% by weight, and the content of Ce in the magnesium alloy is 0.8% by weight. Wherein the mass ratio of Y and Zn is 2.5.

[0049] The preparation method of the LPSO phase strengthened high damping rare earth magnesium alloy comprises the following steps:

[0050] Step 1: with pure magnesium ingot (above 99.5wt%), pure Zn ingot (above 99.5wt%), Mg-25Y master alloy and Mg-20Ce master alloy and MnCl 2 Particles are raw materials, weighed and prepared according to the weight percentage of Y 2.5wt%, Ce 0.8wt%, Zn 1.0wt%, Mn0.6wt%, and the balance is Mg, and the total amount of raw materials is 1kg;

[0051] Step 2: Preheat and dry the pu...

Embodiment 3

[0054] This embodiment provides an LPSO phase-strengthened high-damping rare earth magnesium alloy. The raw material composition and weight percentage content are: rare earth elements: 3.8%, Zn: 1.2%, Mn: 1.0%, and the balance is Mg.

[0055] The rare earth elements in this embodiment include Y and Ce, the content of Y in the magnesium alloy is 2.8% by weight, and the content of Ce in the magnesium alloy is 1.0% by weight. Wherein the mass ratio of Y and Zn is about 2.33.

[0056] The preparation method of the LPSO phase strengthened high damping rare earth magnesium alloy comprises the following steps:

[0057] Step 1: with pure magnesium ingot (above 99.5wt%), pure Zn ingot (above 99.5wt%), Mg-25Y master alloy and Mg-20Ce master alloy and MnCl 2 Particles are used as raw materials, and the raw materials are weighed and prepared according to the weight percentage of Y 2.8wt%, Ce 1.0wt%, Zn 1.2wt%, Mn1.0wt%, and the balance is Mg. The total amount of raw materials is 1kg;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com