HB460MPa-grade high-strength high-tenacity fire-crack-resisting wear-resistant steel and producing method thereof

A high-strength, high-toughness technology, applied in the field of HB460MPa grade high-strength and high-toughness fire-crack-resistant wear-resistant steel, can solve the problems of reduced service life and safety factor, easy cracking of wear-resistant steel, and reduced crack resistance. Achieve the effect of making up for the decrease in strength and wear resistance, improving strength and wear resistance, and improving wear resistance and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

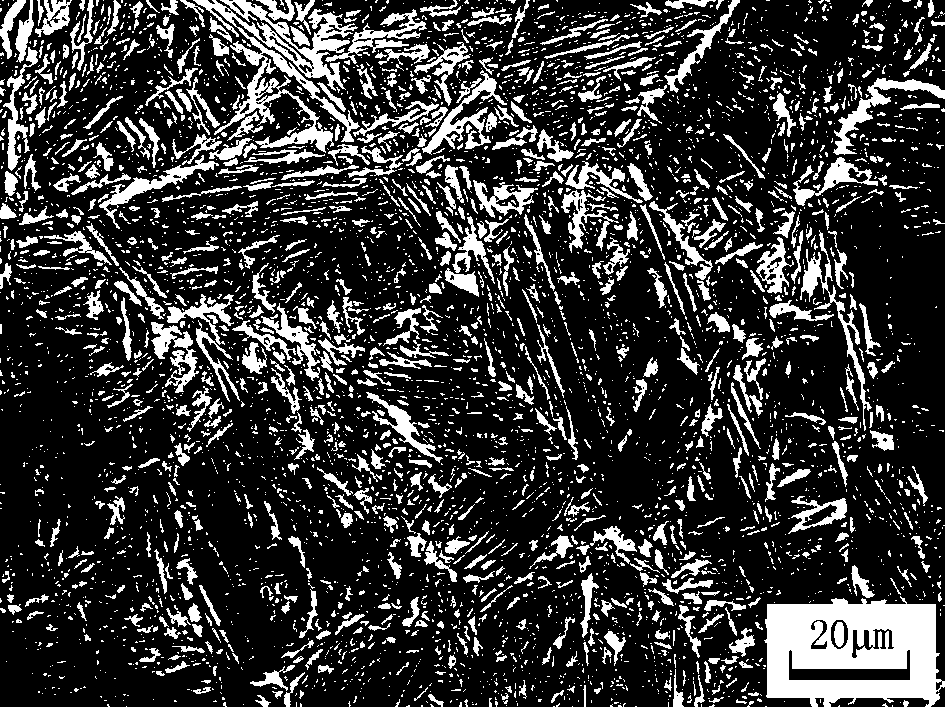

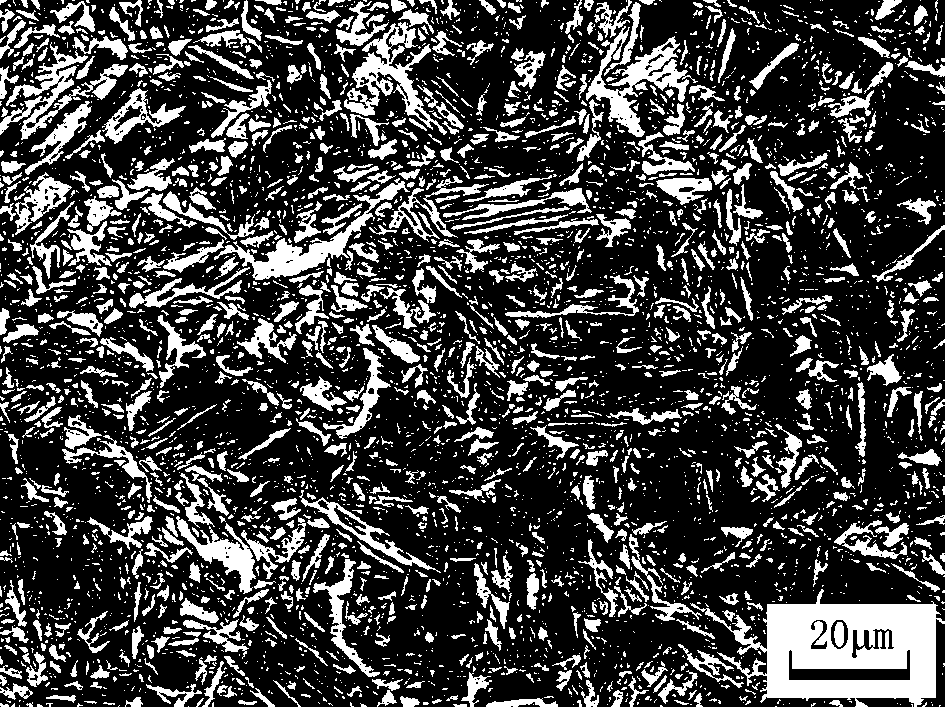

Image

Examples

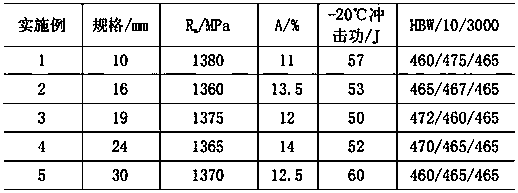

Embodiment 1

[0037] A HB460MPa-grade high-strength, high-toughness fire-cut crack-resistant wear-resistant steel, the steel contains the following chemical components in mass percentages: C: 0.15%, Si: 0.45%, Mn: 1.60%, P: 0.012%, S : 0.010%, Cr: 0.36%, Mo: 0.72%, Nb: 0.043%, Ti: 0.019%, B: 0.0025%, Als: 0.035%, N: 0.0032%, and the rest are Fe and trace impurity elements.

[0038] A production method of HB460MPa grade high-strength high-toughness fire-cut crack-resistant wear-resistant steel, the main production process steps are as follows:

[0039] (1) Slab: Converter smelting-LF furnace refining-RH vacuum treatment, and continuous casting into 200mm thick continuous casting slab, the superheat of molten steel in the tundish is 5°C, the thickness of liquid slag layer is 9mm, and the casting slab casting speed is 0.8m / min;

[0040] (2) Billet heating: set the billet heating temperature to 1200°C, hold time for 3.54 hours, and the upper heating temperature of the heating furnace is 10°C ...

Embodiment 2

[0045] A crack-resistant high-strength wear-resistant steel with a Brinell hardness of 450 and its processing method, its components and weight percentages: C: 0.24%, Si: 0.25%, Mn: 1.35%, P: 0.014%, S: ≤ 0.009%, Cr: 0.30%, Mo: 0.65%, Nb: 0.053%, Ti: 0.028%, B: 0.0035%, Als: 0.038%, N: 0.0030%, and the rest are Fe and trace impurity elements.

[0046] A production method of HB460MPa grade high-strength high-toughness fire-cut crack-resistant wear-resistant steel, the main production process steps are as follows:

[0047] (1) Slab: Converter smelting-LF furnace refining-RH vacuum treatment, and continuous casting into 200mm thick continuous casting slab, tundish molten steel superheat 8℃, liquid slag layer thickness 10mm, casting slab casting speed 0.85m / min;

[0048] (2) Billet heating: set the billet heating temperature to 1215°C, holding time for 3.8 hours, and the upper heating temperature of the heating furnace is 16°C higher than the lower heating temperature;

[0049]...

Embodiment 3

[0053] A crack-resistant high-strength wear-resistant steel with a Brinell hardness of 450 and its processing method, its components and weight percentages: C: 0.19%, Si: 0.37%, Mn: 1.53%, P: 0.012%, S: ≤ 0.008%, Cr: 0.42%, Mo: 0.56%, Nb: 0.048%, Ti: 0.023%, B: 0.0024%, Als: 0.029%, N: 0.0028%, and the rest are Fe and trace impurity elements.

[0054] A production method of HB460MPa grade high-strength high-toughness fire-cut crack-resistant wear-resistant steel, the main production process steps are as follows:

[0055] (1) Slab: Converter smelting-LF furnace refining-RH vacuum treatment, and continuous casting into 200mm thick continuous casting slab, tundish molten steel superheat 15℃, liquid slag layer thickness 14mm, casting slab casting speed 0.9m / min;

[0056] (2) Billet heating: set the billet heating temperature to 1220°C, holding time for 3.7 hours, and the upper heating temperature of the heating furnace is 20°C higher than the lower heating temperature;

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com