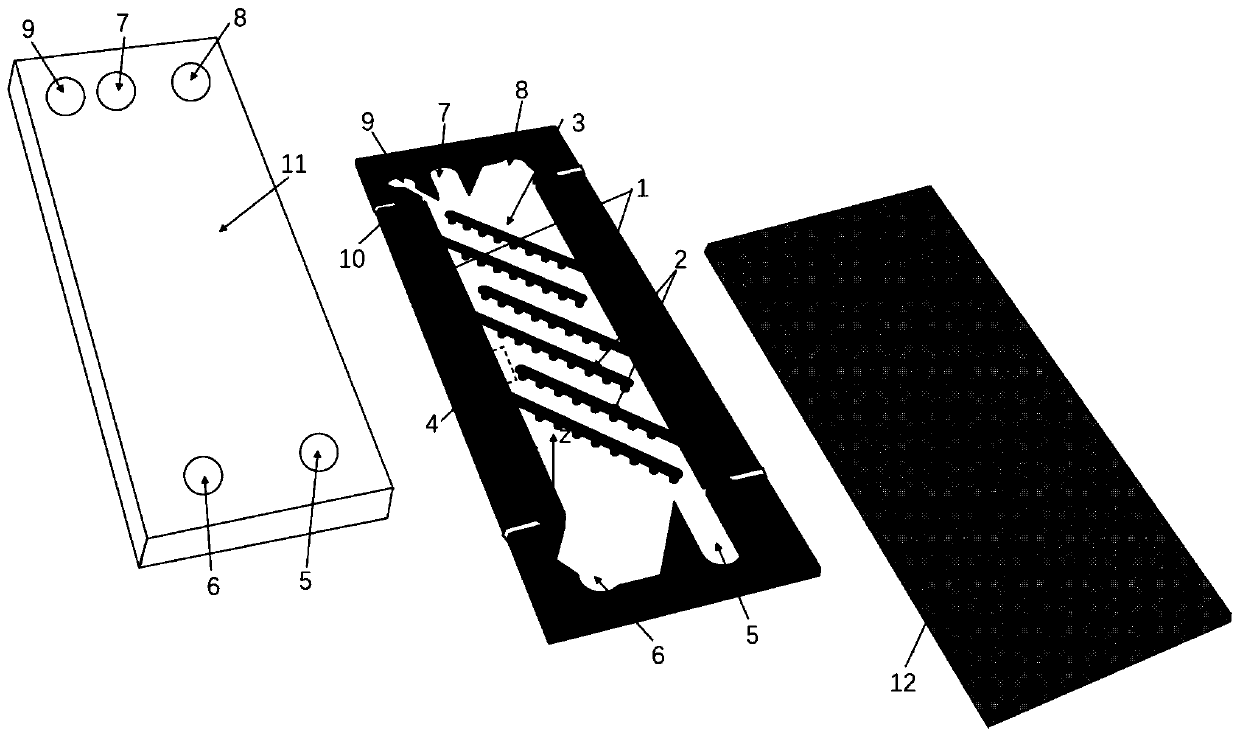

Slide rail type dielectrophoresis electrode structure for high-throughput continuous flow cell separation

An electrode structure and slide rail technology, applied in the field of cell sorting, can solve the problems of controlling cell trajectory, complex silicon-based electrode processing technology, and low work efficiency, so as to improve work efficiency, realize three-dimensional control and separation, and improve separation The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

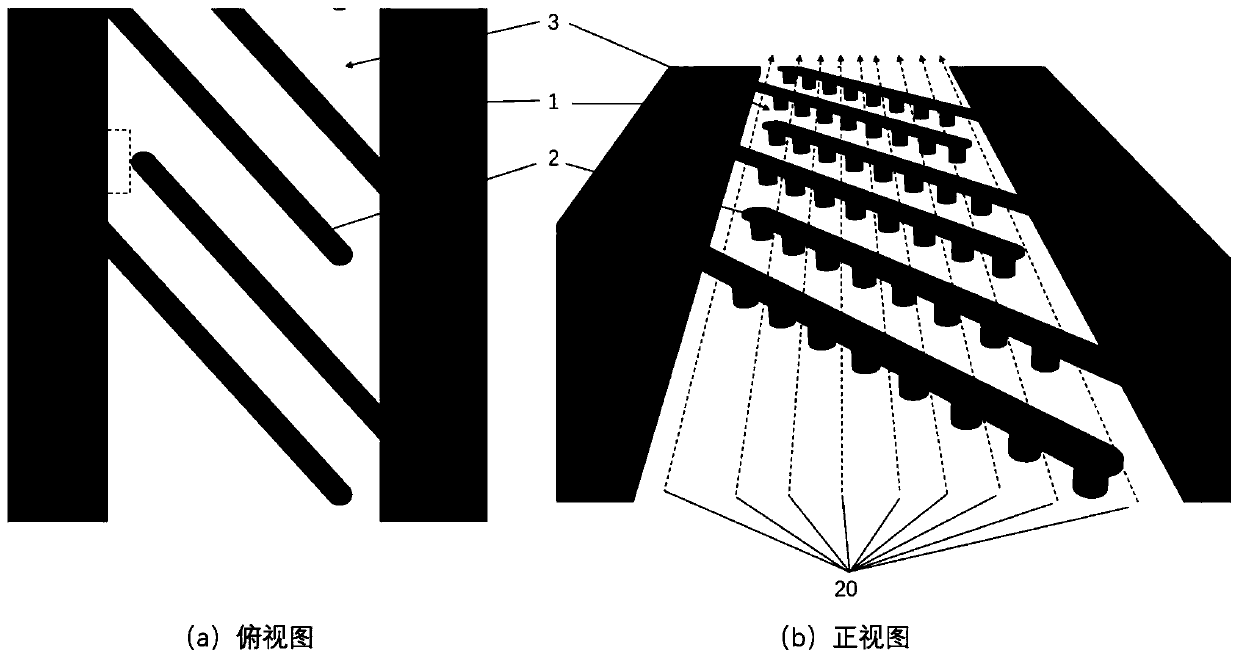

Method used

Image

Examples

Embodiment 1

[0072] In this example, the microchip prepared by the slide-rail electrode structure obtained in the above embodiment and live / dead HeLa cells were used to test the effect of cell separation. The specific steps are as follows:

[0073] Extract the adherent HeLa cells and suspend them in the cell culture medium, take out about 1.5ml of the cell suspension and place it in a small centrifuge tube with a volume of 1.5ml, and treat it in a water bath environment at 65°C for 15 minutes. To kill the cells, centrifuge the treated cells and replace the solution with a 300 mM D-mannitol solution, then use propidium iodide (PI) to stain the dead cells for two minutes; add calcein to the remaining live cell suspension to Live cells were stained for 10 min. The live / dead cells after staining are mixed in the 300mM D-mannitol solution with a conductivity of 0.01S / m according to the concentration ratio of live cells: dead cells = 10:1, and the concentration of live cells in the resulting mix...

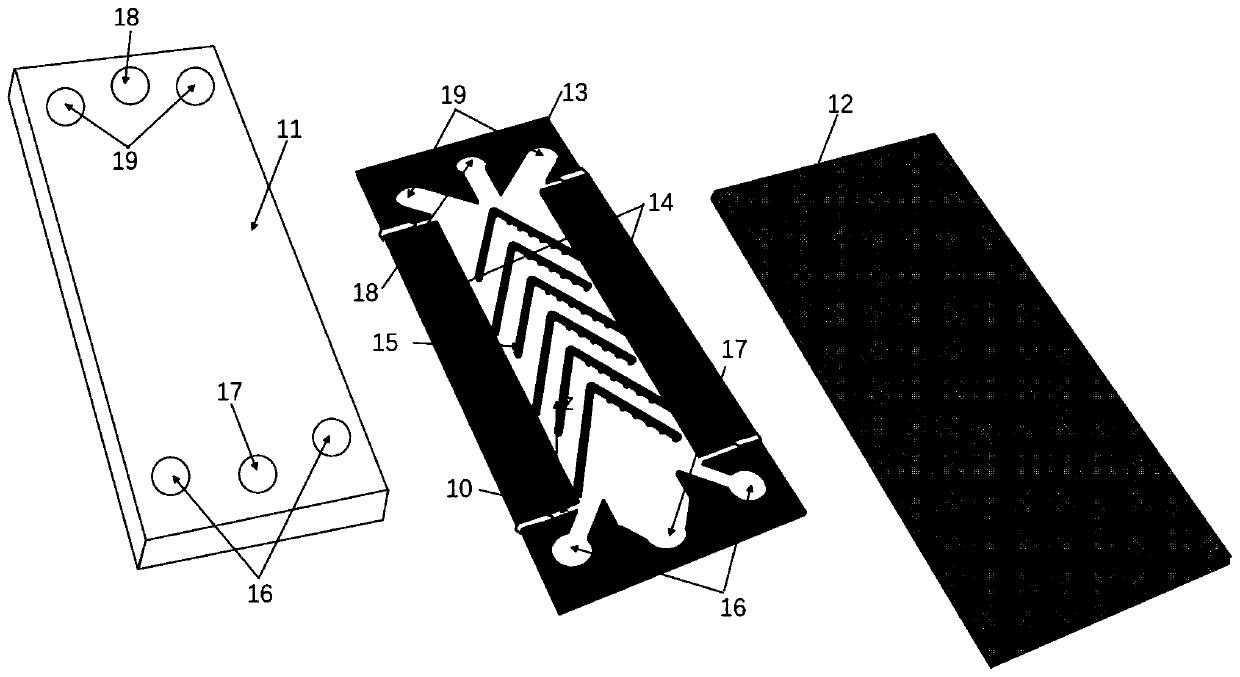

Embodiment 2

[0076] In this example, the microfluidic chip prepared by the V-shaped slide rail electrode structure obtained in the above embodiment and the mixed solution of HeLa cells and polystyrene microspheres were used to test the effect of particle sorting. The specific steps are as follows:

[0077] Extract adherent HeLa cells and suspend them in cell culture medium, add calcein for 10 minutes of staining, then centrifuge the cell suspension and replace the solution with 300mM D-mannitol with a conductivity of 0.01S / m solution. After centrifugation, 7 μm microspheres were added to the cell solution to obtain a cell concentration of 1.2×10 7 A / ml, 7μm microsphere concentration is 1×10 6 A / ml mixed solution. The solution is injected into the above-mentioned microfluidic chip from the middle sample inlet 18 at a flow rate of 1.2ml / h, and the buffer solution (0.01S / m 300mM D-mannitol solution). A sinusoidal signal with an amplitude of 35Vpp and a frequency of 400kHz is input from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com