Oxidation resisting andrias davidianus peptide Jiang-flavor wine and preparation method thereof

A giant salamander peptide sauce fragrant wine and anti-oxidation technology, which is applied in the preparation and fermentation of alcoholic beverages, can solve problems such as unrealizable and no temperature data is given, and achieve the effect of improving antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 Antioxidant giant salamander peptide sauce-flavored wine:

[0015] Its preparation method is as follows:

[0016] (1) Wash and chop giant salamander meat;

[0017] (2) Mix the ground salamander meat with water at a material-to-liquid ratio of 1:3, and adjust the initial pH to 5;

[0018] (3) Add papain according to the ratio of 6200U / g, and hydrolyze at 60°C for 4.5h;

[0019] (4) Enzyme inactivation: after the completion of hydrolysis, inactivate the enzyme at 100°C for 10 minutes;

[0020] (5) Filtrate the feed liquid after deactivating the enzyme, and collect the hydrolysis filtrate;

[0021] (6) subjecting the polypeptide hydrolyzate to vacuum freeze-drying under reduced pressure to obtain freeze-dried powder of giant salamander polypeptide;

[0022] (7) Mix 2% with 38-53% vol Maotai-flavored liquor, precipitate, and centrifuge to prepare clear and transparent giant salamander peptide Maotai-flavored liquor.

Embodiment 2

[0024] (1) Wash and chop giant salamander meat;

[0025] (2) Mix the ground salamander meat with water at a material-to-liquid ratio of 1:5, and adjust the initial pH to 4.5;

[0026] (3) Add papain according to the ratio of 5900U / g, and hydrolyze at 50°C for 4.5h;

[0027] (4) Enzyme inactivation: after the completion of hydrolysis, inactivate the enzyme at 100°C for 10 minutes;

[0028] (5) Filtrate the feed liquid after deactivating the enzyme, and collect the hydrolysis filtrate;

[0029] (6) subjecting the polypeptide hydrolyzate to vacuum freeze-drying under reduced pressure to obtain freeze-dried powder of giant salamander polypeptide;

[0030] (7) Mix 1% with 38-53% vol Maotai-flavored liquor, precipitate, and centrifuge to prepare clear and transparent giant salamander peptide Maotai-flavored liquor.

Embodiment 3

[0032] (1) Wash and chop giant salamander meat;

[0033] (2) Mix the ground salamander meat with water at a material-to-liquid ratio of 1:4, and adjust the initial pH to 4;

[0034] (3) Add papain according to the ratio of 6000U / g, and hydrolyze at 55°C for 4h;

[0035] (4) Enzyme inactivation: after the completion of hydrolysis, inactivate the enzyme at 100°C for 10 minutes;

[0036] (5) Filtrate the feed liquid after deactivating the enzyme, and collect the hydrolysis filtrate;

[0037] (6) subjecting the polypeptide hydrolyzate to vacuum freeze-drying under reduced pressure to obtain freeze-dried powder of giant salamander polypeptide;

[0038] (7) Mix 1.5% with 38-53% vol Maotai-flavored liquor, precipitate, and centrifuge to prepare clear and transparent giant salamander peptide Maotai-flavored liquor.

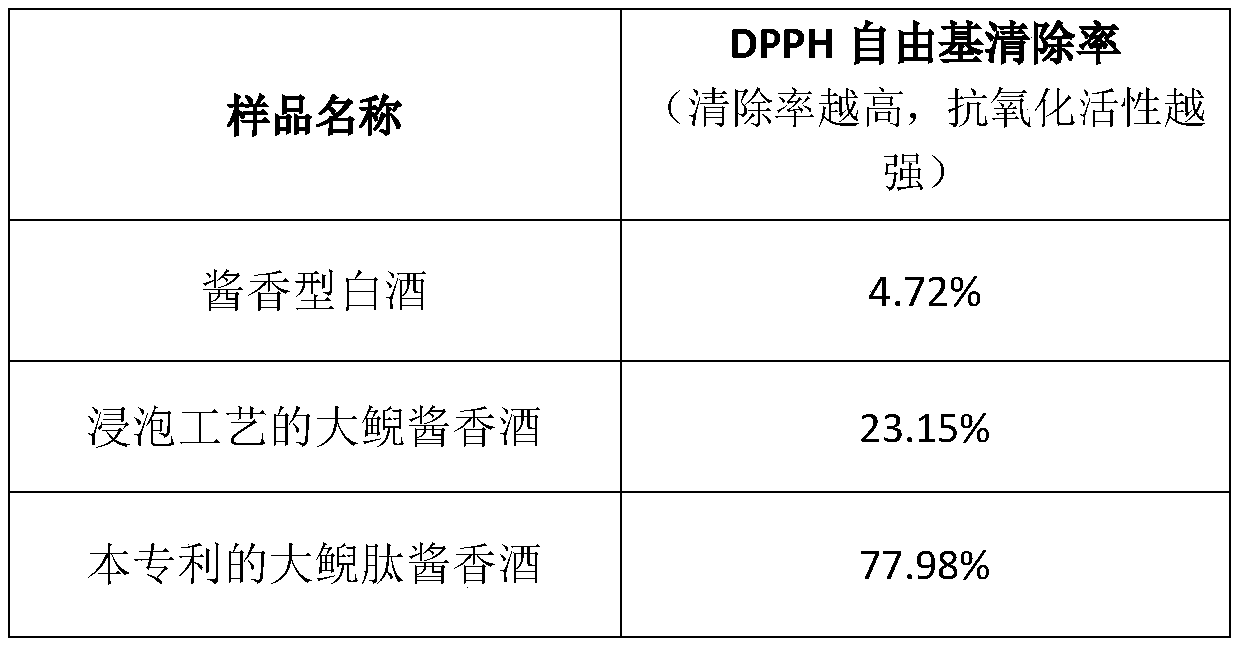

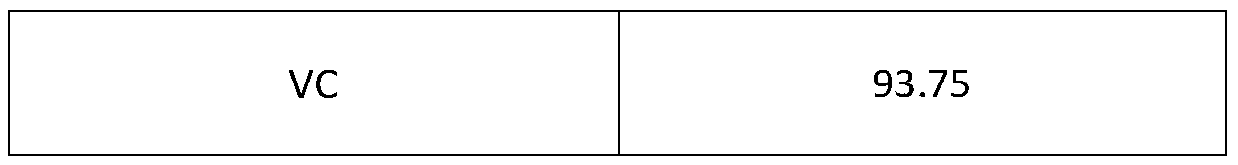

[0039] Comparative data on antioxidant activity of giant salamander sauce-flavored wine

[0040]

[0041]

[0042] It can be seen from the data in the above tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com