Preparation method of modified carbon nanosphere lubricating oil additive

A technology of lubricating oil additives and nanospheres, which is applied in the direction of additives, nanocarbons, lubricating compositions, etc., can solve problems such as unsatisfactory dispersion effects, dispersion problems, ineffective stability, entanglement dispersion, etc., to reduce the friction coefficient and bite load, easy to control, and the effect of improving the load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

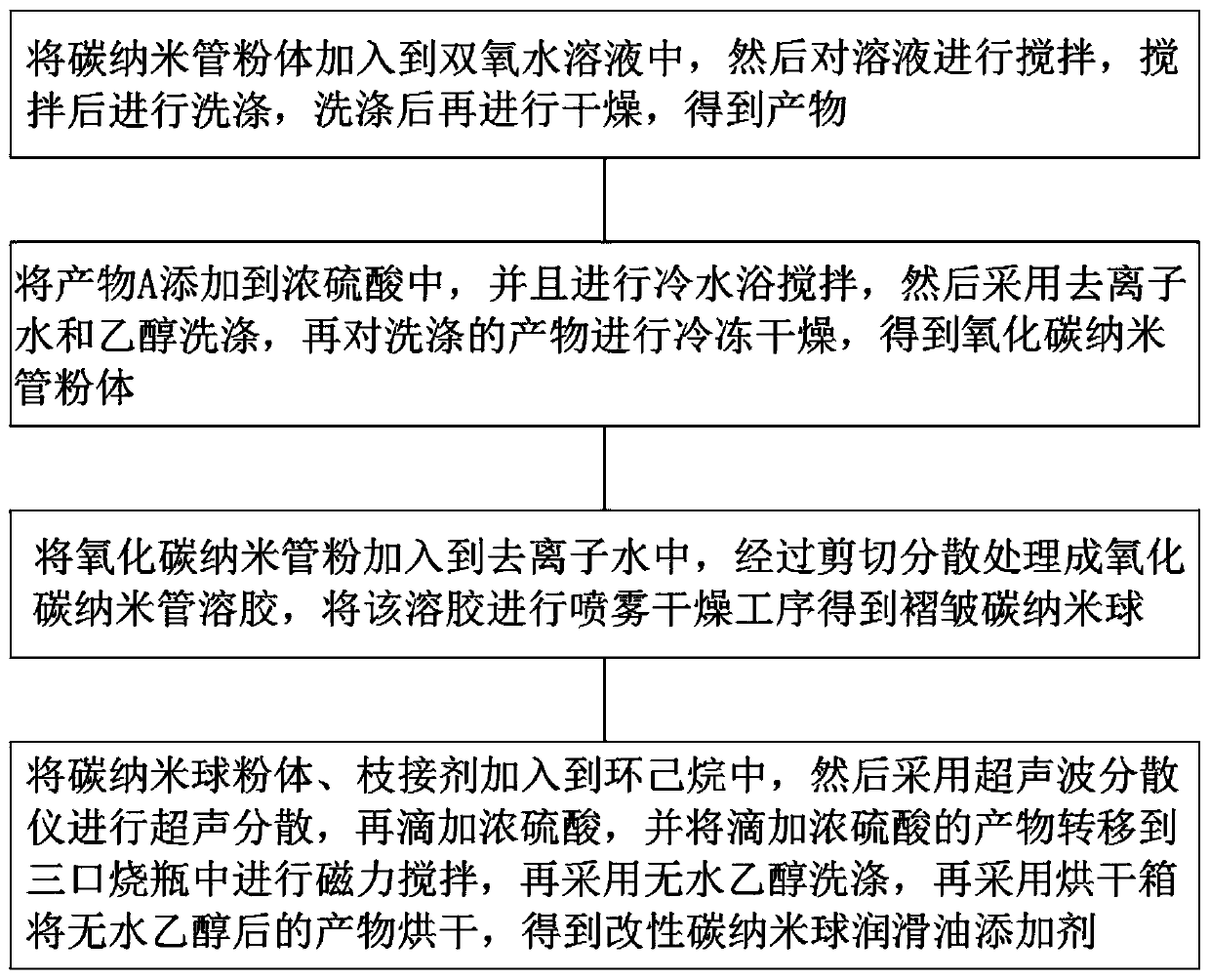

[0027] In this example, the preparation method of the modified carbon nanosphere lubricating oil is as follows:

[0028] (1) Add 1 g of multi-walled carbon nanotube powder into 150 mL of hydrogen peroxide solution, stir at 80° C. for 8 hours, then wash with deionized water three times, and dry at 60° C. for 8 hours to obtain product A.

[0029] (2) Add product A to 200mL sulfuric acid solution, stir in a cold water bath (2-10°C) for 12 hours, wash with deionized water and ethanol for 5 times, and freeze-dry at -15°C for 12 hours to obtain oxidized carbon nanotube powder ;

[0030] (3), adding deionized water to the oxidized carbon nanotube powder, processed into 50mL oxidized carbon nanotube sol (8mg / mL) through shear dispersion, the shear dispersion rate was 10000r / min, and the shear time was 1 hour. The sol was spray-dried to obtain a wrinkled carbon nanotube sphere powder, and the spray-drying temperature was 150° C.

[0031] (4) Add 0.5g of carbon nanotube sphere powder,...

Embodiment 2

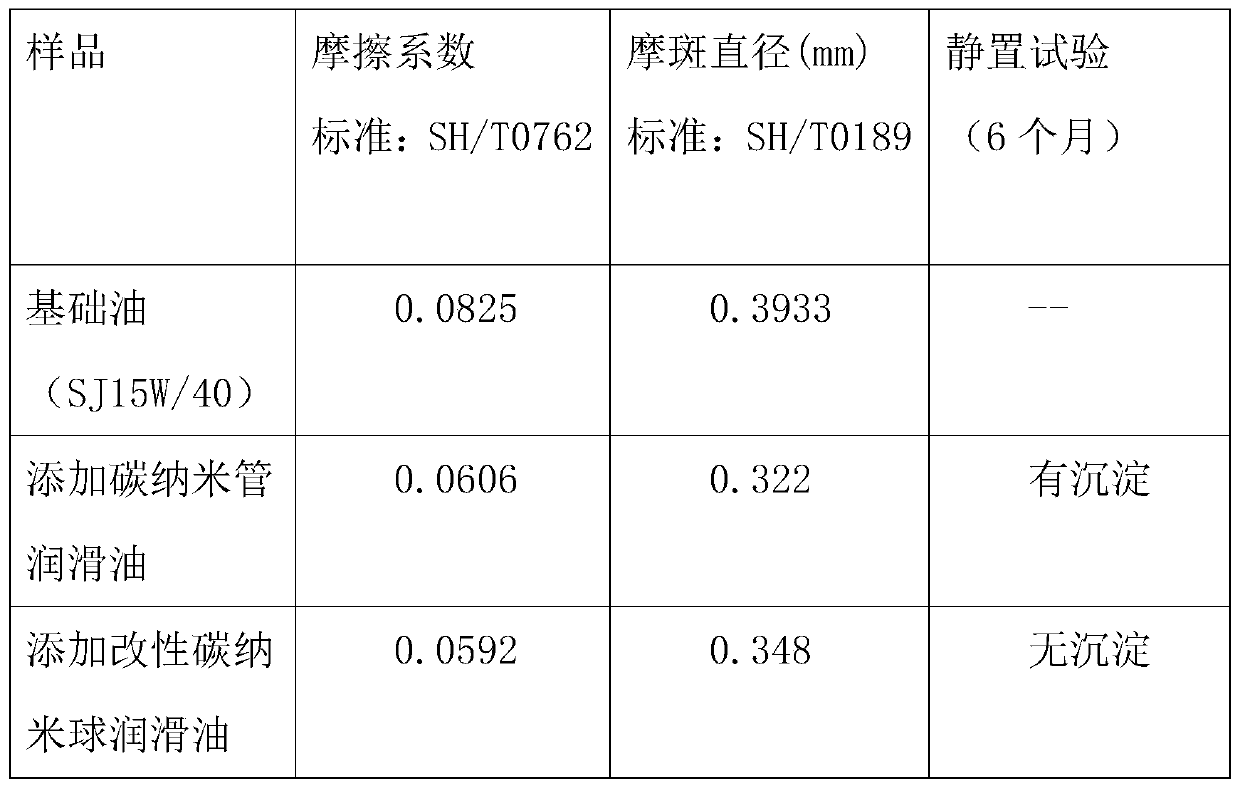

[0033] Add 0.005g of modified carbon nanospheres (modified carbon nano-lubricating oil additive) and 0.005g of carbon nanotubes to 50mL of base lubricating oil (SJ15W / 40), disperse at a high speed of 5000r / min for 30min, and then 10000r / min After cutting for 30 minutes, two kinds of carbon nano-lubricating oil products were obtained. After being tested by a four-ball machine, the modified carbon nano-ball lubricating oil did not settle after standing for 6 months, and the friction coefficient was better than that of carbon nano-tube lubricating oil and base oil.

Embodiment 3

[0035] Add 3.5g of modified carbon nanospheres (modified carbon nano-lubricating oil additive) to 4L of base lubricating oil, disperse at a high speed of 5000r / min for 30min, and then shear at 10000r / min for 1h to obtain a finished carbon nano-lubricating oil; The base oil added with lubricating oil is compared with the road test test, and the test results show that the oil saving rate of the modified carbon nanosphere lubricating oil compared with the base oil is 4-5%.

[0036] From the experimental data in Table 2 and Table 3, it can be seen that the preparation method of the modified carbon nanosphere lubricating oil additive of the present invention is mainly based on the principle of adjusting the microscopic linear structure of carbon nanotubes into a spherical structure, relying on the synergistic effect of chemical modification and physical granulation , transforming carbon nanotubes from a linear structure into a three-dimensional wrinkled spherical structure, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com