High-temperature energy-saving anticorrosive coating material for sintering pallet metal baffle, and applications thereof

A technology for sintering trolleys and anti-corrosion coatings, applied in anti-corrosion coatings, fireproof coatings, coatings, etc., can solve the problems of aggravated corrosion of metal baffles and decreased life of baffles, and achieve reduced sintering energy consumption, increased service life, and multiple The effect of comprehensive benefits

Active Publication Date: 2019-12-31

BAOSHAN IRON & STEEL CO LTD

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, due to the recycling of dust in the sinter, a large amount of K, Na, Pb, Zn and other harmful elements are enriched. These harmful elements intensify the corrosion of the metal baffle, and also cause the life of the baffle to decrease.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

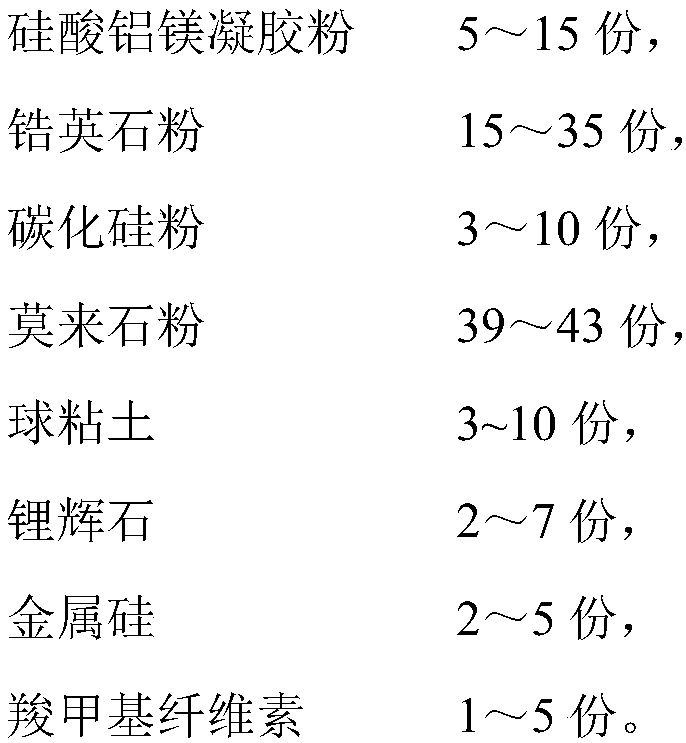

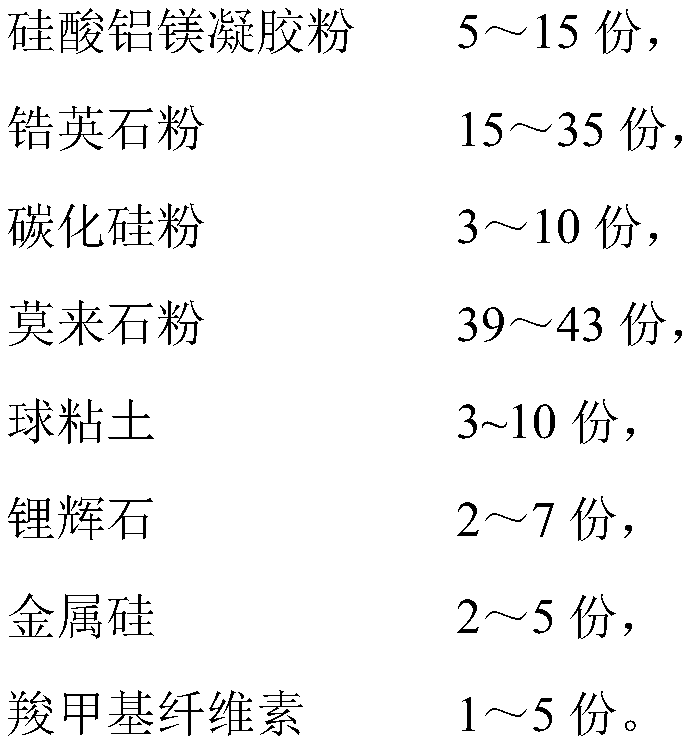

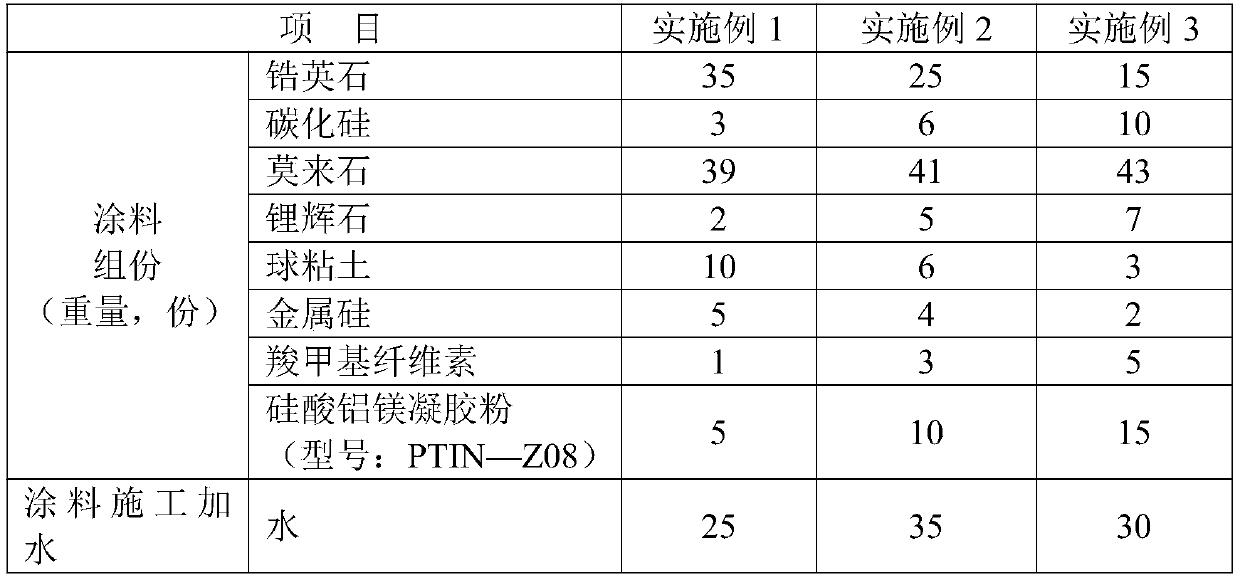

[0026] Prepare according to the following table 1 raw material:

[0027] The coating composition of table 1 embodiment 1-3

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a high-temperature energy-saving anticorrosive coating material for a sintering pallet metal baffle, and an application method thereof, wherein the coating material comprises,by weight, 15-35 parts of zirconite powder, 3-10 parts of silicon carbide powder, 39-43 parts of mullite powder, 3-10 parts of ball clay, 2-7 parts of spodumene, 2-5 parts of metal silicon and 5-15 parts of magnesium aluminum silicate gel powder. During the application, water is added to the coating material to prepare a fine slurry, the surface of a metal baffle is sprayed or coated with the fine slurry, and the coating is firmly attached to the surface of the metal baffle after drying and heat treatment so as to form a high-temperature-resistant energy-saving anti-corrosion ceramic coating.According to the invention, the coating material can reflect the heat of the material layer, reduce the temperature of the inner wall of the baffle, and protect the inner wall surface of the metal baffle from being corroded so as to prolong the service life of the baffle, achieve the energy-saving effect and easily reduce the production cost of sintered ore.

Description

technical field [0001] The invention belongs to the technical field of inorganic materials, in particular to the field of anti-corrosion coatings, and more specifically relates to a high-temperature energy-saving anti-corrosion coating for sintering trolley baffles. Background technique [0002] The most widely used sintering equipment in ironworks is the belt sintering machine, and the sintering machine trolley is composed of the trolley body, baffle plate, heat insulation pad, grate bars, wheels and so on. The baffle of the belt sintering machine trolley is one of the main wearing parts. The baffle is generally cast with ferritic ductile iron. Due to the harsh working conditions, it is easy to deform and crack when working under high temperature and severe cold and hot conditions, and the service life is generally shortened by 3 to 6 months. Therefore improving the service life of the baffle plate is one of the urgent problems to be solved in the production of the sinteri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D1/00C09D5/08C09D7/61C09D7/65

CPCC09D1/00C09D5/08C09D5/18C09D7/61C09D7/65

Inventor 甘菲芳李咸伟毛晓明向家发胡子国

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com