Modified graphite flame retardant, all-water-blown polyurethane foam prepared from modified graphite flame retardant, and preparation method of all-water-blown polyurethane foam

A technology of polyurethane foam and full water foaming, which is applied in the field of polyurethane foam to achieve the effect of increased oxygen index, less additive amount and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

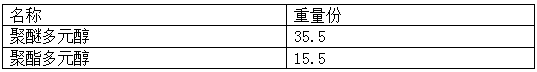

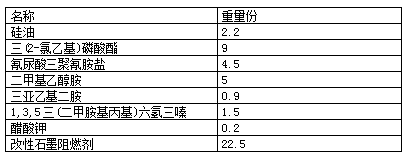

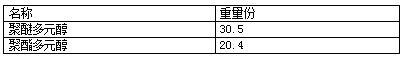

[0025] A kind of all-water foaming polyurethane foam containing modified graphite flame retardant, it is characterized in that described this all-water foaming polyurethane foam is made of polyether polyol, polyester polyol, catalyst, silicone oil, modified graphite flame-retardant agent, synergistic flame retardant, foaming agent, stabilizer, and polymerized isocyanate, the mass parts of the above components are: 20-40 parts of polyether polyol, 15-45 parts of polyester polyol, 2-6 parts of catalyst 1.5-2.5 parts of silicone oil, 20-40 parts of modified graphite flame retardant, 6-20 parts of synergistic flame retardant, 3-7 parts of foaming agent, 5-8 parts of stabilizer, 0.8-1.5 parts of polymerized isocyanate , the polyether polyol refers to a polyether polyol with an average hydroxyl functionality of 2-8 and a hydroxyl value of 200-800 mgKOH / g; the polyester polyol refers to an average hydroxyl functionality of 2-5, A polyester polyol with a hydroxyl value of 150-400 mgKO...

Embodiment 1

[0033] (1) Preparation of modified expandable graphite: a. Shaping process: put the expandable graphite into a mechanical impact mill for shaping, then classify with a vibrating screen, return to re-production if it is less than 80 mesh, and only enter 80-150 mesh In the next modification section, more than 150 mesh will be processed separately; b. Modification process: put the 80-150 mesh expandable graphite obtained in step a into the mixer, and perform low-speed stirring at a speed of 50-85r / min. Molecular surface modifier, after stirring for 10-15 minutes, increase the speed to 150-200r / min, stir for 20-30 minutes, and then sieve through 80 meshes to obtain modified expandable graphite. The polymer surface modification Polyvinylpyrrolidone is used as an agent;

[0034] (2) Preparation of expandable graphite flame retardant: add the modified expandable graphite in step (1) to a dispersing suspending agent, and mix evenly in a stainless steel stirrer at a low speed below 500...

Embodiment 2

[0042] (1) Preparation of modified expandable graphite: a. Shaping process: put the expandable graphite into a mechanical impact mill for shaping, then classify with a vibrating screen, return to re-production if it is less than 80 mesh, and only enter 80-150 mesh In the next modification section, more than 150 mesh will be processed separately; b. Modification process: put the 80-150 mesh expandable graphite obtained in step a into the mixer, and perform low-speed stirring at a speed of 50-85r / min. Molecular surface modifier, after stirring for 10-15 minutes, increase the speed to 150-200r / min, stir for 20-30 minutes, and then sieve through 80 meshes to obtain modified expandable graphite. The polymer surface modification Polyethylene glycol for agent;

[0043] (2) Preparation of expandable graphite flame retardant: add the modified expandable graphite in step (1) to a dispersing suspending agent, and mix evenly in a stainless steel stirrer at a low speed below 500r / min to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com